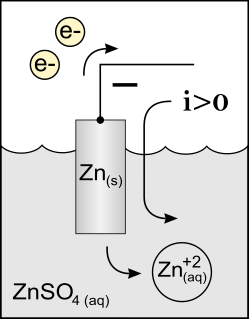

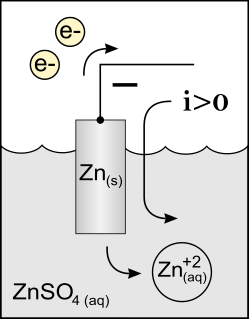

An anode is an electrode through which the conventional current enters into a polarized electrical device. This contrasts with a cathode, an electrode through which conventional current leaves an electrical device. A common mnemonic is ACID for "anode current into device". The direction of conventional current in a circuit is opposite to the direction of electron flow, so electrons flow out the anode into the outside circuit. In a galvanic cell, the anode is the electrode at which the oxidation reaction occurs.

A cathode is the electrode from which a conventional current leaves a polarized electrical device. This definition can be recalled by using the mnemonic CCD for Cathode Current Departs. A conventional current describes the direction in which positive charges move. Electrons have a negative electrical charge, so the movement of electrons is opposite to that of the conventional current flow. Consequently, the mnemonic cathode current departs also means that electrons flow into the device's cathode from the external circuit.

Electrochemistry is the branch of physical chemistry that studies the relationship between electricity, as a measurable and quantitative phenomenon, and identifiable chemical change, with either electricity considered an outcome of a particular chemical change or vice versa. These reactions involve electric charges moving between electrodes and an electrolyte. Thus electrochemistry deals with the interaction between electrical energy and chemical change.

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit. The word was coined by William Whewell at the request of the scientist Michael Faraday from two Greek words: elektron, meaning amber, and hodos, a way.

Electroplating is a process that uses an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode. The term is also used for electrical oxidation of anions on to a solid substrate, as in the formation of silver chloride on silver wire to make silver/silver-chloride electrodes. Electroplating is primarily used to change the surface properties of an object, but may also be used to build up thickness on undersized parts or to form objects by electroforming.

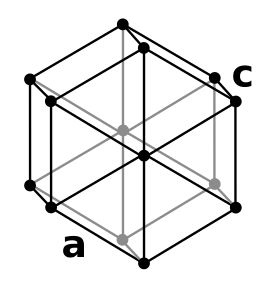

The Hall–Héroult process is the major industrial process for smelting aluminium. It involves dissolving aluminium oxide (alumina) in molten cryolite, and electrolysing the molten salt bath, typically in a purpose-built cell. The Hall–Héroult process applied at industrial scale happens at 940–980°C and produces 99.5–99.8% pure aluminium. Recycled aluminum requires no electrolysis, thus it does not end up in this process.

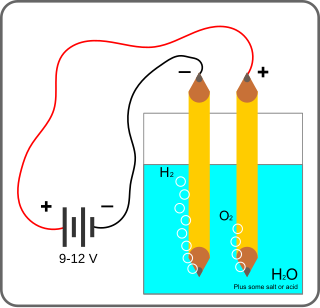

An electrolytic cell is an electrochemical cell that drives a non-spontaneous redox reaction through the application of electrical energy. They are often used to decompose chemical compounds, in a process called electrolysis—the Greek word lysis means to break up.

Copper extraction refers to the methods used to obtaining copper from its ores. The conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.

The electrolysis of brine is an industrial process for the electrolysis of sodium chloride solutions. It is the technology used to produce chlorine and sodium hydroxide, which are commodity chemicals required by industry. 35 million tons of chlorine were prepared by this process in 1987. Industrial scale production began in 1892.

A regenerative fuel cell or reverse fuel cell (RFC) is a fuel cell run in reverse mode, which consumes electricity and chemical B to produce chemical A. By definition, the process of any fuel cell could be reversed. However, a given device is usually optimized for operating in one mode and may not be built in such a way that it can be operated backwards. Standard fuel cells operated backwards generally do not make very efficient systems unless they are purpose-built to do so as with high-pressure electrolysers, regenerative fuel cells, solid-oxide electrolyser cells and unitized regenerative fuel cells.

The Betts electrolytic process is an industrial process for purification of lead from bullion. Lead obtained from its ores is impure because lead is a good solvent for many metals. Often these impurities are tolerated, but the Betts electrolytic process is used when high purity lead is required, especially for bismuth-free lead.

The Castner process is a process for manufacturing sodium metal by electrolysis of molten sodium hydroxide at approximately 330 °C. Below that temperature, the melt would solidify; above that temperature, the molten sodium would start to dissolve in the melt.

Electrowinning, also called electroextraction, is the electrodeposition of metals from their ores that have been put in solution via a process commonly referred to as leaching. Electrorefining uses a similar process to remove impurities from a metal. Both processes use electroplating on a large scale and are important techniques for the economical and straightforward purification of non-ferrous metals. The resulting metals are said to be electrowon.

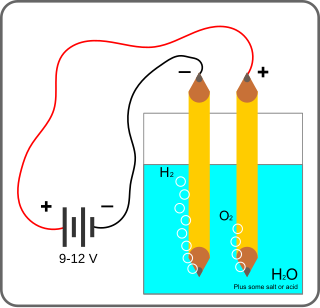

Electrolysis of water is the decomposition of water into oxygen and hydrogen gas due to the passage of an electric current. The reaction has a standard potential of −1.23 V, meaning it ideally requires a potential difference of 1.23 volts to split water.

In metallurgy, refining consists of purifying an impure metal. It is to be distinguished from other processes such as smelting and calcining in that those two involve a chemical change to the raw material, whereas in refining, the final material is usually identical chemically to the original one, only it is purer. The processes used are of many types, including pyrometallurgical and hydrometallurgical techniques.

Aluminium smelting is the process of extracting aluminium from its oxide, alumina, generally by the Hall-Héroult process. Alumina is extracted from the ore bauxite by means of the Bayer process at an alumina refinery.

This article presents the industrial and laboratory methods to prepare elemental chlorine.

The IsaKidd Technology is a copper electrorefining and electrowinning technology that was developed independently by Copper Refineries Proprietary Limited (“CRL”), a Townsville, Queensland subsidiary of MIM Holdings Limited, and at the Falconbridge Limited (“Falconbridge”) now-dismantled Kidd Creek refinery that was at Timmins, Ontario. It is based around the use of reusable cathode starter sheets for copper electrorefining and the automated stripping of the deposited “cathode copper” from them.

Galvanic corrosion is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. A similar galvanic reaction is exploited in primary cells to generate a useful electrical voltage to power portable devices.