Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other dross, which makes it brittle and not useful directly as a material except for limited applications.

Wrought iron is an iron alloy with a very low carbon content in contrast to that of cast iron. It is a semi-fused mass of iron with fibrous slag inclusions, which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welded, but is more difficult to weld electrically.

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe

3O

4, 72.4% Fe), hematite (Fe

2O

3, 69.9% Fe), goethite (FeO(OH), 62.9% Fe), limonite (FeO(OH)·n(H2O), 55% Fe), or siderite (FeCO3, 48.2% Fe).

Slag is a by-product of smelting (pyrometallurgical) ores and recycled metals. Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be classified as ferrous, ferroalloy or non-ferrous/base metals. Within these general categories, slags can be further categorized by their precursor and processing conditions. "Slag generated from the EAF process can contain toxic metals, which can be hazardous to human and environmental health".

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being supplied above atmospheric pressure.

Hossein Khosrow Ali Vaziri, better known by his ring name the Iron Sheik, was an Iranian professional wrestler, amateur wrestler, and actor. He was the first, and so far only, Iranian champion in WWE history, having won the WWF World Heavyweight Championship in 1983.

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper ores consists of a series of physical, chemical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.

In materials science, a refractory is a material that is resistant to decomposition by heat or chemical attack that retains its strength and rigidity at high temperatures. They are inorganic, non-metallic compounds that may be porous or non-porous, and their crystallinity varies widely: they may be crystalline, polycrystalline, amorphous, or composite. They are typically composed of oxides, carbides or nitrides of the following elements: silicon, aluminium, magnesium, calcium, boron, chromium and zirconium. Many refractories are ceramics, but some such as graphite are not, and some ceramics such as clay pottery are not considered refractory. Refractories are distinguished from the refractory metals, which are elemental metals and their alloys that have high melting temperatures.

An open-hearth furnace or open hearth furnace is any of several kinds of industrial furnace in which excess carbon and other impurities are burnt out of pig iron to produce steel. Because steel is difficult to manufacture owing to its high melting point, normal fuels and furnaces were insufficient for mass production of steel, and the open-hearth type of furnace was one of several technologies developed in the nineteenth century to overcome this difficulty. Compared with the Bessemer process, which it displaced, its main advantages were that it did not expose the steel to excessive nitrogen, was easier to control, and permitted the melting and refining of large amounts of scrap iron and steel.

Streak or streaking may refer to:

Dross is a mass of solid impurities floating on a molten metal or dispersed in the metal, such as in wrought iron. It forms on the surface of low-melting-point metals such as tin, lead, zinc or aluminium or alloys by oxidation of the metal. For higher melting point metals and alloys such as steel and silver, oxidized impurities melt and float making them easy to pour off.

An electric arc furnace (EAF) is a furnace that heats material by means of an electric arc.

A bloomery is a type of metallurgical furnace once used widely for smelting iron from its oxides. The bloomery was the earliest form of smelter capable of smelting iron. Bloomeries produce a porous mass of iron and slag called a bloom. The mix of slag and iron in the bloom, termed sponge iron, is usually consolidated and further forged into wrought iron. Blast furnaces, which produce pig iron, have largely superseded bloomeries.

Electrometallurgy is a method in metallurgy that uses electrical energy to produce metals by electrolysis. It is usually the last stage in metal production and is therefore preceded by pyrometallurgical or hydrometallurgical operations. The electrolysis can be done on a molten metal oxide which is used for example to produce aluminium from aluminium oxide via the Hall-Hérault process. Electrolysis can be used as a final refining stage in pyrometallurgical metal production (electrorefining) and it is also used for reduction of a metal from an aqueous metal salt solution produced by hydrometallurgy (electrowinning).

A cupola or cupola furnace is a melting device used in foundries that can be used to melt cast iron, Ni-resist iron and some bronzes. The cupola can be made almost any practical size. The size of a cupola is expressed in diameters and can range from 1.5 to 13 feet. The overall shape is cylindrical and the equipment is arranged vertically, usually supported by four legs. The overall look is similar to a large smokestack.

José Ibarra is a Mexican Luchador (wrestler) who is best known as Escoria / Dark Escoria, a face character that works for Lucha Libre AAA Worldwide (AAA). Ibarra has been part of The Black Family since it was formed, but left the stable in October 2010. During his time in the Black Family, Escoria was also a member of Lucha Libre Latina (LLL) and La Secta del Mesias, its predecessor La Secta Cibernetica and La Legión Extranjera.

Archaeometallurgical slag is slag discovered and studied in the context of archaeology. Slag, the byproduct of iron-working processes such as smelting or smithing, is left at the iron-working site rather than being moved away with the product. As it weathers well, it is readily available for study. The size, shape, chemical composition and microstructure of slag are determined by features of the iron-working processes used at the time of its formation.

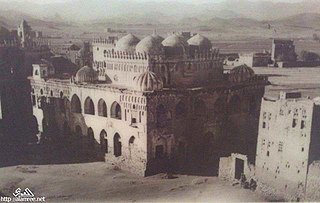

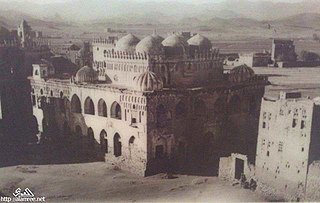

Qadad or qudad is a waterproof plaster surface, made of a lime plaster treated with slaked lime and oils and fats. The technique is over a thousand years old, with the remains of this early plaster still seen on the standing sluices of the ancient Marib Dam.

Kemondo Iron Age Sites or KM2 and KM3 are Early Iron Age complex industrial archaeological sites in Kemondo ward, Bukoba Rural District, Kagera Region, Tanzania, excavated by a team led by archaeologist Peter Schmid in the late 1970s and 1980s. The excavations aimed at better understanding the iron smelting process and its ritual aspects in East Africa. At the KM2 and KM3 sites, Schmidt tested the hypothesis that the high combustion temperature of furnaces, discovered to be between 1,350–1,400 °C (2,460–2,550 °F), was caused by the preheating of air blasts. Preheating has been suggested to be a distinct feature of African Early Iron Age smelting techniques by ethnographic observations of the Haya people of northwestern Tanzania.

Scoria bricks are a type of blue-grey brick made from slag, originally manufactured from the waste of the steelworks of Teesside, common across the North-East of England. The bricks were also exported around the world and can be found in Canada, West Indies, Netherlands, United States, India and South America.