A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature where it becomes easier to shape by forging, or to the point where work hardening no longer occurs. The metal is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. However, depending on the metal type, it may require an oil quench or a salt brine instead; many metals require more than plain water hardening. The slack tub also provides water to control the fire in the forge.

Coke is a grey, hard, and porous fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air — a destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern.

A lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide). The chemical equation for this reaction is

Anthracite, often referred to as hard coal, is a hard, compact variety of coal that has a submetallic luster. It has the highest carbon content, the fewest impurities, and the highest energy density of all types of coal and is the highest ranking of coals.

Incineration is a waste treatment process that involves the combustion of organic substances contained in waste materials. Incineration and other high-temperature waste treatment systems are described as "thermal treatment". Incineration of waste materials converts the waste into ash, flue gas and heat. The ash is mostly formed by the inorganic constituents of the waste and may take the form of solid lumps or particulates carried by the flue gas. The flue gases must be cleaned of gaseous and particulate pollutants before they are dispersed into the atmosphere. In some cases, the heat generated by incineration can be used to generate electric power.

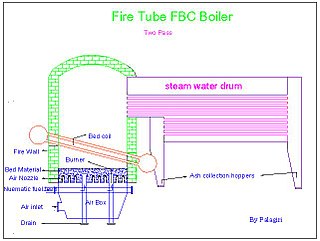

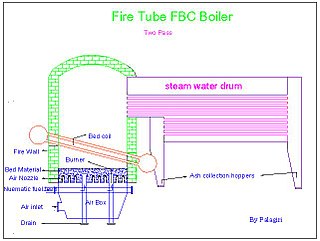

Fluidized bed combustion (FBC) is a combustion technology used to burn solid fuels.

A stove is an enclosed space in which fuel is burned to heat either the space in which the stove is situated, or items placed on the heated stove.

A briquette is a compressed block of coal dust or other combustible biomass material such as charcoal, sawdust, wood chips, peat, or paper used for fuel and kindling to start a fire. The term derives from the French word brique meaning brick.

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler. Most are somewhat box-shaped, hence the name. The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler.

A waste-to-energy plant is a waste management facility that combusts wastes to produce electricity. This type of power plant is sometimes called a trash-to-energy, municipal waste incineration, energy recovery, or resource recovery plant.

A fossil fuel power station is a thermal power station which burns a fossil fuel such as coal, natural gas, or petroleum to produce electricity. Central station fossil fuel power plants are designed on a large scale for continuous operation. In many countries, such plants provide most of the electrical energy used. Fossil fuel power stations have machinery to convert the heat energy of combustion into mechanical energy, which then operates an electrical generator. The prime mover may be a steam turbine, a gas turbine or, in small plants, a reciprocating internal combustion engine. All plants use the energy extracted from expanding gas, either steam or combustion gases.

Although different energy conversion methods exist, all thermal power station conversion methods have efficiency limited by the Carnot efficiency and therefore produce waste heat.

A fire iron is any metal instrument for tending a fire.

A pulverized coal-fired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal that is blown into the firebox.

Co-firing is the combustion of two different types of materials at the same time. One of the advantages of co-firing is that an existing plant can be used to burn a new fuel, which may be cheaper or more environmentally friendly. For example, biomass is sometimes co-fired in existing coal plants instead of new biomass plants. Another example is that biomass primary fuel fractions can be cofired with waste-derived fuels in biomass plants leading to an environmentally friendly destruction of waste fractions and cost-effective heat and power production. Co-firing can also be used to improve the combustion of fuels with low energy content. For example, landfill gas contains a large amount of carbon dioxide, which is non-combustible. If the landfill gas is burned without removing the carbon dioxide, the equipment may not perform properly or emissions of pollutants may increase. Co-firing it with natural gas increases the heat content of the fuel and improves combustion and equipment performance. As long as the electricity or heat produced with the biomass and landfill gas was otherwise going to be produced with non-renewable fuels, the benefits are essentially equivalent whether they are cofired or combusted alone. Also, co-firing can be used to lower the emission of some pollutants. For example, co-firing biomass with coal results in less sulfur emissions than burning coal by itself.

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steam-generating furnaces of fossil fuel power plants.

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates. Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant. As the main energy-consuming and greenhouse-gas–emitting stage of cement manufacture, improvement of kiln efficiency has been the central concern of cement manufacturing technology.

JEA Northside Generating Station in Jacksonville, Florida is a major power plant, one of the three power plants owned and operated by JEA, Jacksonville's municipal utilities service. It produces electricity by burning coal and petroleum coke at Units 1 and 2, formerly the largest circulating fluidized-bed combustors, (CFBs), in the world. These combustors, completed in 2002 and rated at 297.5 megawatts each, produce enough electricity to light more than 250,000 households. In addition, Unit ST3 produces 505 megawatts of electricity by burning residual fuel oil and/or natural gas.

A wood-burning stove is a heating appliance capable of burning wood fuel and wood-derived biomass fuel, such as sawdust bricks. Generally the appliance consists of a solid metal closed firebox, often lined by fire brick, and one or more air controls. The first wood burning stove was patented in Strasbourg in 1557, two centuries before the Industrial Revolution, which would make iron an inexpensive and common material, so such stoves were high end consumer items and only gradually spread in use.

A multi-fuel stove is similar to a wood-burning stove in appearance and design. Multifuel refers to the capability of the stove to burn wood and also coal, wood pellets, or peat. Stoves that have a grate for the fire to burn on and a removable ash pan are generally considered multi-fuel stoves. If the fire simply burns on a bed of ash, it is a wood-only fuelled appliance, and cannot be used for coal or peat.

The circulating fluidized bed (CFB) is a developing technology for coal combustion to achieve lower emission of pollutants. By using this technology, up to 95% of pollutants can be absorbed before being emitted to the atmosphere.