An engineering drawing, a type of technical drawing, is used to fully and clearly define requirements for engineered items.

Engineering tolerance is the permissible limit or limits of variation in:

- a physical dimension;

- a measured value or physical property of a material, manufactured object, system, or service;

- other measured values ;

- in engineering and safety, a physical distance or space (tolerance), as in a truck (lorry), train or boat under a bridge as well as a train in a tunnel ;

- in mechanical engineering the space between a bolt and a nut or a hole, etc.

Fibre-reinforced plastic (FRP) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass, carbon, aramid, or basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use.

A datum reference or just datum is some important part of an object—such as a point, line, plane, hole, set of holes, or pair of surfaces—that serves as a reference in defining the geometry of the object and (often) in measuring aspects of the actual geometry to assess how closely they match with the nominal value, which may be an ideal, standard, average, or desired value. For example, on a car's wheel, the lug nut holes define a bolt circle that is a datum from which the location of the rim can be defined and measured. This matters because the hub and rim need to be concentric to within close limits. The concept of datums is used in many fields, including carpentry, metalworking, needlework, geometric dimensioning and tolerancing (GD&T), aviation, surveying, and others.

The ABEC scale is an industry accepted standard for the tolerances of a ball bearing. It was developed by the Annular Bearing Engineering Committee (ABEC) of the American Bearing Manufacturers Association (ABMA). The ABEC scale is designed to provide bearing manufacturers dimensional specifications that meet the standards of precision bearings in a specified class. Manufacturers who produce equipment that require bearings must also know the dimensional tolerances to design parts that will accommodate a bearing.

Nominal Pipe Size (NPS) is a North American set of standard sizes for pipes used for high or low pressures and temperatures. "Nominal" refers to pipe in non-specific terms and identifies the diameter of the hole with a non-dimensional number. Specific pipe is identified by pipe diameter and another non-dimensional number for wall thickness referred to as the Schedule. NPS is often incorrectly called National Pipe Size, due to confusion with the American standard for pipe threads, "national pipe straight", which also abbreviates as "NPS". The European and international designation equivalent to NPS is DN, in which sizes are measured in millimetres, see ISO 6708. The term NB is also frequently used interchangeably with DN.

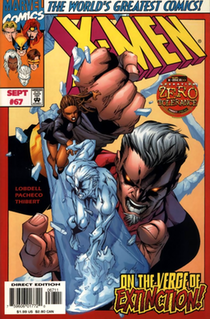

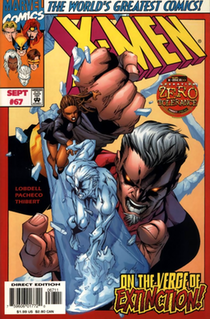

"Operation: Zero Tolerance" was a crossover storyline that ran through Marvel Comics' X-Men related titles during 1997. The story followed from the "Onslaught Saga" and focused on individuals, including Bastion and Henry Peter Gyrich, within the United States government and their attempts to use their positions to hunt down all mutants across the country. Within the story, the program is known as "Operation: Zero Tolerance".

Position Tolerance is a geometric dimensioning and tolerancing (GD&T) location control used on engineering drawings to specify desired location, as well as allowed deviation to the position of a feature on a part. Position tolerance must only be applied to features of size, which requires that the feature have at least two opposable points.

IT Grade refers to the International Tolerance Grade of an industrial process defined in ISO 286. This grade identifies what tolerances a given process can produce for a given dimension.

In a technical drawing, a basic dimension is a theoretically exact dimension, given from a datum to a feature of interest. In Geometric dimensioning and tolerancing, basic dimensions are defined as a numerical value used to describe the theoretically exact size, profile, orientation or location of a feature or datum target.

Engineering fits are generally used as part of geometric dimensioning and tolerancing when a part or assembly is designed. In engineering terms, the "fit" is the clearance between two mating parts, and the size of this clearance determines whether the parts can move independently from each other, or are then temporarily or even permanently joined. Engineering fits are generally described as a "shaft and hole" but are not limited to just round components. ISO is the internationally accepted standard for defining engineering fits, but ANSI is often still used in North America.

In engineering and machining, an allowance is a planned deviation between an exact dimension and a nominal or theoretical dimension, or between an intermediate-stage dimension and an intended final dimension. The unifying abstract concept is that a certain amount of difference allows for some known factor of compensation or interference. For example, an area of excess metal may be left because it is needed to complete subsequent machining. Common cases are listed below. An allowance, which is a planned deviation from an ideal, is contrasted with a tolerance, which accounts for expected but unplanned deviations.

Engineering drawing abbreviations and symbols are used to communicate and detail the characteristics of an engineering drawing. This list includes abbreviations common to the vocabulary of people who work with engineering drawings in the manufacture and inspection of parts and assemblies.

The distinction between real value and nominal value occurs in many fields. From a philosophical viewpoint, nominal value represents an accepted condition, which is a goal or an approximation, as opposed to the real value, which is always present.

The Office for Democratic Institutions and Human Rights (ODIHR) is the principal institution of the Organization for Security and Cooperation in Europe (OSCE) dealing with the "human dimension" of security. The Office, originally named Office for Free Elections, was created in 1990 by the Charter of Paris and established in 1991. The name of the office was changed in 1992 to reflect the broadened mandate it received at the 1992 Helsinki Summit.

ISO 128 is an international standard (ISO), about the general principles of presentation in technical drawings, specifically the graphical representation of objects on technical drawings.

Production drawings are complete sets of drawings that detail the manufacturing and assembly of products.

Herbert Marcuse was a German-American philosopher, sociologist, and political theorist, associated with the Frankfurt School of Critical Theory. Born in Berlin, Marcuse studied at the Humboldt University of Berlin and then at Freiburg, where he received his PhD. He was a prominent figure in the Frankfurt-based Institute for Social Research – what later became known as the Frankfurt School. He was married to Sophie Wertheim (1924–1951), Inge Neumann (1955–1973), and Erica Sherover (1976–1979). In his written works, he criticized capitalism, modern technology, historical materialism and entertainment culture, arguing that they represent new forms of social control.