Gallery

- Hydraulic system testing

- Drop test of shipping container for missile

- Engineers in NASA dynamic test chamber

- Crash test of car striking a wall

- Fire testing materials and structures

A physical test is a qualitative or quantitative procedure that consists of determination of one or more characteristics of a given product, process or service according to a specified procedure. [1] Often this is part of an experiment.

Physical testing is common in physics, engineering, and quality assurance.

Physical testing might have a variety of purposes, such as:

Some physical testing is performance testing which covers a wide range of engineering or functional evaluations where a material, product, or system is not specified by detailed material or component specifications. Rather, emphasis is on the final measurable performance characteristics. Testing can be a qualitative or quantitative procedure. Many Acceptance testing protocols employ performance testing e.g. In the stress testing of a new design of chair.

Configuration management (CM) is a systems engineering process for establishing and maintaining consistency of a product's performance, functional, and physical attributes with its requirements, design, and operational information throughout its life. The CM process is widely used by military engineering organizations to manage changes throughout the system lifecycle of complex systems, such as weapon systems, military vehicles, and information systems. Outside the military, the CM process is also used with IT service management as defined by ITIL, and with other domain models in the civil engineering and other industrial engineering segments such as roads, bridges, canals, dams, and buildings.

Rebar, known when massed as reinforcing steel or reinforcement steel, is a steel bar or mesh of steel wires used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has weak tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface is often "deformed" with ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

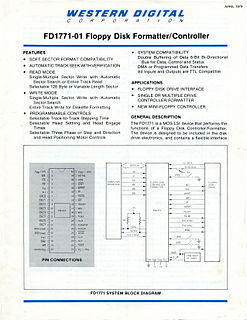

A datasheet, data-sheet, or spec sheet is a document that summarizes the performance and other characteristics of a product, machine, component, material, subsystem, or software in sufficient detail that allows a buyer to understand what the product is and a design engineer to understand the role of the component in the overall system. Typically, a datasheet is created by the manufacturer and begins with an introductory page describing the rest of the document, followed by listings of specific characteristics, with further information on the connectivity of the devices. In cases where there is relevant source code to include, it is usually attached near the end of the document or separated into another file. Datasheets are created, stored, and distributed via product information management or product data management systems.

Engineering tolerance is the permissible limit or limits of variation in:

In chemistry, a chemical test is a qualitative or quantitative procedure designed to identify, quantify, or characterise a chemical compound or chemical group.

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time.

A United States defense standard, often called a military standard, "MIL-STD", "MIL-SPEC", or (informally) "MilSpecs", is used to help achieve standardization objectives by the U.S. Department of Defense.

Environmental stress screening (ESS) refers to the process of exposing a newly manufactured or repaired product or component to stresses such as thermal cycling and vibration in order to force latent defects to manifest themselves by permanent or catastrophic failure during the screening process. The surviving population, upon completion of screening, can be assumed to have a higher reliability than a similar unscreened population.

A measurement systems analysis (MSA) is a thorough assessment of a measurement process, and typically includes a specially designed experiment that seeks to identify the components of variation in that measurement process.

The Air Movement and Control Association International, Inc. (AMCA) is a long-established American trade body that sets standards for Heating, Ventilation and Air Conditioning (HVAC) equipment. It is best known for its ratings in fan balance and vibration, aerodynamic performance, air density, speed and efficiency.

A test method is a method for a test in science or engineering, such as a physical test, chemical test, or statistical test. It is a definitive procedure that produces a test result. In order to ensure accurate and relevant test results, a test method should be "explicit, unambiguous, and experimentally feasible.", as well as effective and reproducible.

An independent test organization is an organization, person, or company that tests products, materials, software, etc. according to agreed requirements. The test organization can be affiliated with the government or universities or can be an independent testing laboratory. They are independent because they are not affiliated with the producer nor the user of the item being tested: no commercial bias is present. These "contract testing" facilities are sometimes called "third party" testing or evaluation facilities.

A specification often refers to a set of documented requirements to be satisfied by a material, design, product, or service. A specification is often a type of technical standard.

A technical standard is an established norm or requirement for a repeatable technical task. It is usually a formal document that establishes uniform engineering or technical criteria, methods, processes, and practices. In contrast, a custom, convention, company product, corporate standard, and so forth that becomes generally accepted and dominant is often called a de facto standard.

MIL-PRF-38535 is a United States military specification that establishes the general performance and verification requirements of single die integrated circuit device type electronics. It is a performance-based specification document defining the general requirements, as well as the quality assurance and reliability requirements, for the manufacture of microelectronic or integrated circuits used in military applications and high-reliability microcircuit application programs.

British Approvals Service for Cables is an independent accredited certification body headquartered in Milton Keynes, United Kingdom. Here, the organization's dedicated testing laboratory also operates which is believed to be the largest of its type in Europe. BASEC was established in 1971 and principally provides product certification services for all types of cable and wire, ancillary products and management systems within the cable industry. The organization maintains operations throughout the world including Africa, Middle East, America, Asia and Europe.

Acceptance sampling uses statistical sampling to determine whether to accept or reject a production lot of material. It has been a common quality control technique used in industry. It is usually done as products leaves the factory, or in some cases even within the factory. Most often a producer supplies a consumer a number of items and a decision to accept or reject the items is made by determining the number of defective items in a sample from the lot. The lot is accepted if the number of defects falls below where the acceptance number or otherwise the lot is rejected.

Package testing or packaging testing involves the measurement of a characteristic or property involved with packaging. This includes packaging materials, packaging components, primary packages, shipping containers, and unit loads, as well as the associated processes.

Tensile testing, also known as tension testing, is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum elongation and reduction in area. From these measurements the following properties can also be determined: Young's modulus, Poisson's ratio, yield strength, and strain-hardening characteristics. Uniaxial tensile testing is the most commonly used for obtaining the mechanical characteristics of isotropic materials. Some materials use biaxial tensile testing. The main difference between these testing machines being how load is applied on the materials.

Analytical quality control, commonly shortened to AQC, refers to all those processes and procedures designed to ensure that the results of laboratory analysis are consistent, comparable, accurate and within specified limits of precision. Constituents submitted to the analytical laboratory must be accurately described to avoid faulty interpretations, approximations, or incorrect results. The qualitative and quantitative data generated from the laboratory can then be used for decision making. In the chemical sense, quantitative analysis refers to the measurement of the amount or concentration of an element or chemical compound in a matrix that differs from the element or compound. Fields such as industry, medicine, and law enforcement can make use of AQC.