Computer-Aided Design (CAD) is the use of computers to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software help protect products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer-aided design and drafting (CADD) are also used.

Computer-aided engineering can be defined as the general usage of technology to aid in tasks related to engineering analysis. Any use of technology to solve or assist engineering issues falls under this umbrella.

NASTRAN is a finite element analysis (FEA) program that was originally developed for NASA in the late 1960s under United States government funding for the aerospace industry. The MacNeal-Schwendler Corporation (MSC) was one of the principal and original developers of the publicly available NASTRAN code. NASTRAN source code is integrated in a number of different software packages, which are distributed by a range of companies.

Mesh generation is the practice of creating a mesh, a subdivision of a continuous geometric space into discrete geometric and topological cells. Often these cells form a simplicial complex. Usually the cells partition the geometric input domain. Mesh cells are used as discrete local approximations of the larger domain. Meshes are created by computer algorithms, often with human guidance through a GUI, depending on the complexity of the domain and the type of mesh desired. A typical goal is to create a mesh that accurately captures the input domain geometry, with high-quality (well-shaped) cells, and without so many cells as to make subsequent calculations intractable. The mesh should also be fine in areas that are important for the subsequent calculations.

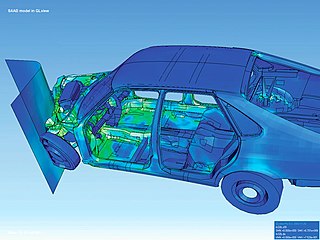

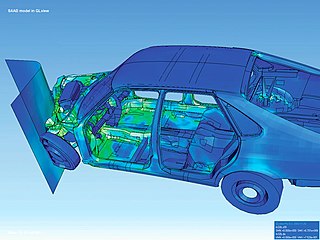

A crash simulation is a virtual recreation of a destructive crash test of a car or a highway guard rail system using a computer simulation in order to examine the level of safety of the car and its occupants. Crash simulations are used by automakers during computer-aided engineering (CAE) analysis for crashworthiness in the computer-aided design (CAD) process of modelling new cars. During a crash simulation, the kinetic energy, or energy of motion, that a vehicle has before the impact is transformed into deformation energy, mostly by plastic deformation (plasticity) of the car body material, at the end of the impact.

Dassault Systèmes Simulia Corp. is a computer-aided engineering (CAE) vendor. Formerly known as Abaqus Inc. and previously Hibbitt, Karlsson & Sorensen, Inc., (HKS), the company was founded in 1978 by David Hibbitt, Bengt Karlsson and Paul Sorensen, and has its headquarters in Providence, Rhode Island.

Altair Engineering Inc. is an American multinational information technology company headquartered in Troy, Michigan. It provides software and cloud solutions for simulation, IoT, high performance computing (HPC), data analytics, and artificial intelligence (AI). Altair Engineering is the creator of the HyperWorks CAE software product, among numerous other software packages and suites. The company was founded in 1985 and went public in 2017. It is traded on the Nasdaq stock exchange under the stock ticker symbol ALTR.

Virtual engineering (VE) is defined as integrating geometric models and related engineering tools such as analysis, simulation, optimization, and decision making tools, etc., within a computer-generated environment that facilitates multidisciplinary collaborative product development. Virtual engineering shares many characteristics with software engineering, such as the ability to obtain many different results through different implementations.

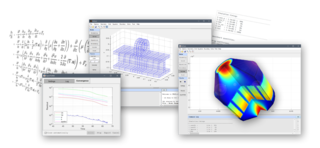

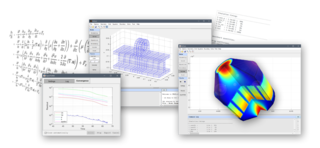

Abaqus FEA is a software suite for finite element analysis and computer-aided engineering, originally released in 1978. The name and logo of this software are based on the abacus calculation tool. The Abaqus product suite consists of five core software products:

- Abaqus/CAE, or "Complete Abaqus Environment". It is a software application used for both the modeling and analysis of mechanical components and assemblies (pre-processing) and visualizing the finite element analysis result. A subset of Abaqus/CAE including only the post-processing module can be launched independently in the Abaqus/Viewer product.

- Abaqus/Standard, a general-purpose Finite-Element analyzer that employs implicit integration scheme (traditional).

- Abaqus/Explicit, a special-purpose Finite-Element analyzer that employs explicit integration scheme to solve highly nonlinear systems with many complex contacts under transient loads.

- Abaqus/CFD, a Computational Fluid Dynamics software application which provides advanced computational fluid dynamics capabilities with extensive support for preprocessing and postprocessing provided in Abaqus/CAE - discontinued in Abaqus 2017 and further releases.

- Abaqus/Electromagnetic, a Computational electromagnetics software application which solves advanced computational electromagnetic problems.

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential.

hp-FEM is a generalization of the finite element method (FEM) for solving partial differential equations numerically based on piecewise-polynomial approximations. hp-FEM originates from the discovery by Barna A. Szabó and Ivo Babuška that the finite element method converges exponentially fast when the mesh is refined using a suitable combination of h-refinements and p-refinements .The exponential convergence of hp-FEM has been observed by numerous independent researchers.

Synopsys Simpleware ScanIP is a 3D image processing and model generation software program developed by Synopsys Inc. to visualise, analyse, quantify, segment and export 3D image data from magnetic resonance imaging (MRI), computed tomography (CT), microtomography and other modalities for computer-aided design (CAD), finite element analysis (FEA), computational fluid dynamics (CFD), and 3D printing. The software is used in the life sciences, materials science, nondestructive testing, reverse engineering and petrophysics.

SVFLUX is a finite element seepage analysis program developed by SoilVision Systems Ltd.. The software is designed to analyze both saturated and unsaturated flow through the ground through the solving of Richard's equation. The program is used in the fields of civil engineering and hydrology in order to analyze seepage and groundwater regional flow. The software is used for the calculation of flow rates, pore-water pressures, and pumping rates associated with regional groundwater flow. The software can be coupled with CHEMFLUX in order to calculate diffusion, advection, and decay rates or with SVHEAT in order to calculate thermal gradients and freeze/thaw fronts.

JMAG is a simulation software used for the development and design of electrical devices. JMAG was originally released in 1983 as a tool to support the design of devices such as motors, actuators, circuit components, and antennas.

ADINA is a commercial engineering simulation software program that is developed and distributed worldwide by ADINA R & D, Inc. The company was founded in 1986 by Dr. Klaus-Jürgen Bathe, and is headquartered in Watertown, Massachusetts, United States. On April 7, 2022, Bentley Systems acquired ADINA R&D, Inc.

Simulation modeling is the process of creating and analyzing a digital prototype of a physical model to predict its performance in the real world. Simulation modeling is used to help designers and engineers understand whether, under what conditions, and in which ways a part could fail and what loads it can withstand. Simulation modeling can also help to predict fluid flow and heat transfer patterns. It analyses the approximate working conditions by applying the simulation software.

FEMtools is a multi-functional, cross-platform and solver-independent family of CAE software programs providing analysis and scripting solutions for many different types of engineering simulation applications. The program is developed, supported and licensed by Dynamic Design Solutions ("DDS") NV, located in Leuven, Belgium.

VisualFEA is a finite element analysis software program for Microsoft Windows and Mac OS X. It is developed and distributed by Intuition Software, Inc. of South Korea, and used chiefly for structural and geotechnical analysis. Its strongest point is its intuitive, user-friendly design based on graphical pre- and postprocessing capabilities. It has educational features for teaching and learning structural mechanics, and finite element analysis through graphical simulation. It is widely used in college-level courses related to structural mechanics and finite element methods.

C3D Toolkit is a proprietary cross-platform geometric modeling kit software developed by Russian by C3D Labs. It's written in C++. It can be licensed by other companies for use in their 3D computer graphics software products. The most widely known software in which C3D Toolkit is typically used are computer aided design (CAD), computer-aided manufacturing (CAM), and computer-aided engineering (CAE) systems.

FEATool Multiphysics is a physics, finite element analysis (FEA), and partial differential equation (PDE) simulation toolbox. FEATool Multiphysics features the ability to model fully coupled heat transfer, fluid dynamics, chemical engineering, structural mechanics, fluid-structure interaction (FSI), electromagnetics, as well as user-defined and custom PDE problems in 1D, 2D (axisymmetry), or 3D, all within a graphical user interface (GUI) or optionally as script files. FEATool has been employed and used in academic research, teaching, and industrial engineering simulation contexts.