Related Research Articles

Thallium is a chemical element with the symbol Tl and atomic number 81. It is a gray post-transition metal that is not found free in nature. When isolated, thallium resembles tin, but discolors when exposed to air. Chemists William Crookes and Claude-Auguste Lamy discovered thallium independently in 1861, in residues of sulfuric acid production. Both used the newly developed method of flame spectroscopy, in which thallium produces a notable green spectral line. Thallium, from Greek θαλλός, thallós, meaning "green shoot" or "twig", was named by Crookes. It was isolated by both Lamy and Crookes in 1862; Lamy by electrolysis, and Crookes by precipitation and melting of the resultant powder. Crookes exhibited it as a powder precipitated by zinc at the international exhibition, which opened on 1 May that year.

Wrought iron is an iron alloy with a very low carbon content in contrast to that of cast iron. It is a semi-fused mass of iron with fibrous slag inclusions, which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welded, but is more difficult to weld electrically.

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

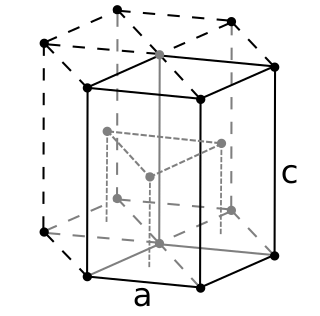

Refractory metals are a class of metals that are extraordinarily resistant to heat and wear. The expression is mostly used in the context of materials science, metallurgy and engineering. The definition of which elements belong to this group differs. The most common definition includes five elements: two of the fifth period and three of the sixth period. They all share some properties, including a melting point above 2000 °C and high hardness at room temperature. They are chemically inert and have a relatively high density. Their high melting points make powder metallurgy the method of choice for fabricating components from these metals. Some of their applications include tools to work metals at high temperatures, wire filaments, casting molds, and chemical reaction vessels in corrosive environments. Partly due to the high melting point, refractory metals are stable against creep deformation to very high temperatures.

Forge welding (FOW), also called fire welding, is a solid-state welding process that joins two pieces of metal by heating them to a high temperature and then hammering them together. It may also consist of heating and forcing the metals together with presses or other means, creating enough pressure to cause plastic deformation at the weld surfaces. The process, although challenging, has been a method of joining metals used since ancient times and is a staple of traditional blacksmithing. Forge welding is versatile, being able to join a host of similar and dissimilar metals. With the invention of electrical welding and gas welding methods during the Industrial Revolution, manual forge-welding has been largely replaced, although automated forge-welding is a common manufacturing process.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

A safety lamp is any of several types of lamp that provides illumination in places such as coal mines where the air may carry coal dust or a build-up of inflammable gases, which may explode if ignited, possibly by an electric spark. Until the development of effective electric lamps in the early 1900s, miners used flame lamps to provide illumination. Open flame lamps could ignite flammable gases which collected in mines, causing explosions; safety lamps were developed to enclose the flame to prevent it from igniting the explosive gases. Flame safety lamps have been replaced for lighting in mining with sealed explosion-proof electric lights, but continue to be used to detect gases.

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disadvantage is that some results are only comparative. The test was pivotal in understanding the fracture problems of ships during World War II.

Titanium hydride normally refers to the inorganic compound TiH2 and related nonstoichiometric materials. It is commercially available as a stable grey/black powder, which is used as an additive in the production of Alnico sintered magnets, in the sintering of powdered metals, the production of metal foam, the production of powdered titanium metal and in pyrotechnics.

Magnalium is an aluminium alloy with 5% magnesium and 95% aluminum.

CSA was a division of Cambridge Information Group and provider of online databases, based in Bethesda, Maryland, before merging with ProQuest of Ann Arbor, Michigan, in 2007. CSA hosted databases of abstracts and developed taxonomic indexing of scholarly articles. These databases were hosted on the CSA Illumina platform and were available alongside add-on products like CSA Illustrata. The company produced numerous bibliographic databases in different fields of the arts and humanities, natural and social sciences, and technology. Thus, coverage included materials science, environmental sciences and pollution management, biological sciences, aquatic sciences and fisheries, biotechnology, engineering, computer science, sociology, linguistics, and other areas.

A dust explosion is the rapid combustion of fine particles suspended in the air within an enclosed location. Dust explosions can occur where any dispersed powdered combustible material is present in high-enough concentrations in the atmosphere or other oxidizing gaseous medium, such as pure oxygen. In cases when fuel plays the role of a combustible material, the explosion is known as a fuel-air explosion.

Exothermic welding, also known as exothermic bonding, thermite welding (TW), and thermit welding, is a welding process that employs molten metal to permanently join the conductors. The process employs an exothermic reaction of a thermite composition to heat the metal, and requires no external source of heat or current. The chemical reaction that produces the heat is an aluminothermic reaction between aluminium powder and a metal oxide.

Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide (FeO), iron(III) oxide, and iron(II,III) oxide.

The Monza ampullae form the largest collection of a specific type of Early Medieval pilgrimage ampullae or small flasks designed to hold holy oil from pilgrimage sites in the Holy Land related to the life of Jesus. They were made in Palestine, probably in the fifth to early seventh centuries, and have been in the Treasury of Monza Cathedral north of Milan in Italy since they were donated by Theodelinda, queen of the Lombards,. Since the great majority of surviving examples of such flasks are those in the Monza group, the term may be used to cover this type of object in general.

Fletcher, Burrows and Company was a coal mining company that owned collieries and cotton mills in Atherton, Greater Manchester, England. Gibfield, Howe Bridge and Chanters collieries exploited the coal mines (seams) of the middle coal measures in the Manchester Coalfield. The Fletchers built company housing at Hindsford and a model village at Howe Bridge which included pithead baths and a social club for its workers. The company became part of Manchester Collieries in 1929. The collieries were nationalised in 1947 becoming part of the National Coal Board.

A spark is an incandescent particle. Sparks may be produced by pyrotechnics, by metalworking or as a by-product of fires, especially when burning wood.

Kenneth Claughan Mills, was head of the Slags group at the National Physical Laboratory and a visiting professor in the Department of Materials at Imperial College London.

References

- ↑ Bill Gunston (27 April 1972). "Mills and Boon monographs and technical library". New Scientist: 219–220.