Related Research Articles

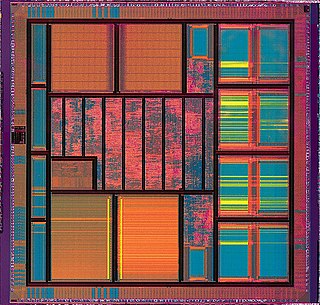

An integrated circuit (IC), also known as a microchip, computer chip, or simply chip, is a small electronic device made up of multiple interconnected electronic components such as transistors, resistors, and capacitors. These components are etched onto a small piece of semiconductor material, usually silicon. Integrated circuits are used in a wide range of electronic devices, including computers, smartphones, and televisions, to perform various functions such as processing and storing information. They have greatly impacted the field of electronics by enabling device miniaturization and enhanced functionality.

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuits (ICs) such as computer processors, microcontrollers, and memory chips. It is a multiple-step photolithographic and physio-chemical process during which electronic circuits are gradually created on a wafer, typically made of pure single-crystal semiconducting material. Silicon is almost always used, but various compound semiconductors are used for specialized applications.

Very-large-scale integration (VLSI) is the process of creating an integrated circuit (IC) by combining millions or billions of MOS transistors onto a single chip. VLSI began in the 1970s when MOS integrated circuit chips were developed and then widely adopted, enabling complex semiconductor and telecommunication technologies. The microprocessor and memory chips are VLSI devices.

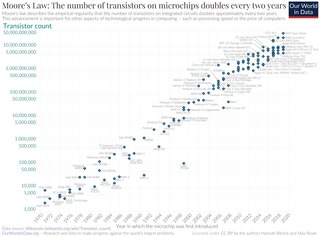

Moore's law is the observation that the number of transistors in an integrated circuit (IC) doubles about every two years. Moore's law is an observation and projection of a historical trend. Rather than a law of physics, it is an empirical relationship linked to gains from experience in production.

National Semiconductor was an American semiconductor manufacturer which specialized in analog devices and subsystems, formerly with headquarters in Santa Clara, California. The company produced power management integrated circuits, display drivers, audio and operational amplifiers, communication interface products and data conversion solutions. National's key markets included wireless handsets, displays and a variety of broad electronics markets, including medical, automotive, industrial and test and measurement applications.

Capital intensity is the amount of fixed or real capital present in relation to other factors of production, especially labor. At the level of either a production process or the aggregate economy, it may be estimated by the capital to labor ratio, such as from the points along a capital/labor isoquant. The inverse of capital intensity is labor intensity. Capital intensity is sometimes associated with industrialism, while labor intensity is sometimes associated with agrarianism.

Taiwan Semiconductor Manufacturing Company Limited is a Taiwanese multinational semiconductor contract manufacturing and design company. It is the world's second-most valuable semiconductor company, the world's largest dedicated independent ("pure-play") semiconductor foundry, and its country's largest company, with headquarters and main operations located in the Hsinchu Science Park in Hsinchu, Taiwan. It is majority owned by foreign investors, and the central government of Taiwan is the largest shareholder. In 2023, the company was ranked 44th in the Forbes Global 2000.

The semiconductor industry is the aggregate of companies engaged in the design and fabrication of semiconductors and semiconductor devices, such as transistors and integrated circuits. It formed around 1960, once the fabrication of semiconductor devices became a viable business. The industry's annual semiconductor sales revenue has since grown to over $481 billion, as of 2018.

Fabless manufacturing is the design and sale of hardware devices and semiconductor chips while outsourcing their fabrication to a specialized manufacturer called a semiconductor foundry. These foundries are typically, but not exclusively, located in the United States, China, and Taiwan. Fabless companies can benefit from lower capital costs while concentrating their research and development resources on the end market. Some fabless companies and pure play foundries may offer integrated-circuit design services to third parties.

Arthur Rock is an American businessman and investor. Based in Silicon Valley, California, he was an early investor in major firms including Intel, Apple, Scientific Data Systems and Teledyne.

The 65 nm process is an advanced lithographic node used in volume CMOS (MOSFET) semiconductor fabrication. Printed linewidths can reach as low as 25 nm on a nominally 65 nm process, while the pitch between two lines may be greater than 130 nm.

Semiconductor Manufacturing International Corporation (SMIC) is a partially state-owned publicly listed Chinese pure-play semiconductor foundry company. It is the largest contract chip maker in mainland China.

In the microelectronics industry, a semiconductor fabrication plant is a factory for semiconductor device fabrication.

PWRficient is a microprocessor series by P.A. Semi where the PA6T-1682M was the only one that became an actual product.

The "14 nanometer process" refers to a marketing term for the MOSFET technology node that is the successor to the "22 nm" node. The "14 nm" was so named by the International Technology Roadmap for Semiconductors (ITRS). Until about 2011, the node following "22 nm" was expected to be "16 nm". All "14 nm" nodes use FinFET technology, a type of multi-gate MOSFET technology that is a non-planar evolution of planar silicon CMOS technology.

The term die shrink refers to the scaling of metal–oxide–semiconductor (MOS) devices. The act of shrinking a die creates a somewhat identical circuit using a more advanced fabrication process, usually involving an advance of lithographic nodes. This reduces overall costs for a chip company, as the absence of major architectural changes to the processor lowers research and development costs while at the same time allowing more processor dies to be manufactured on the same piece of silicon wafer, resulting in less cost per product sold.

ASM is a Dutch headquartered multinational corporation that specializes in the design, manufacturing, sales and service of semiconductor wafer processing equipment for the fabrication of semiconductor devices. ASM's products are used by semiconductor manufacturers in front-end wafer processing in their semiconductor fabrication plants. ASM's technologies include atomic layer deposition, epitaxy, chemical vapor deposition and diffusion.

Vishay Intertechnology, Inc. is an American manufacturer of discrete semiconductors and passive electronic components founded by Polish-born businessman Felix Zandman. Vishay has manufacturing plants in Israel, Asia, Europe, and the Americas where it produces rectifiers, diodes, MOSFETs, optoelectronics, selected integrated circuits, resistors, capacitors, and inductors. Vishay Intertechnology revenues for 2023 were $3.4 billion. At the end of 2023, Vishay had approximately 23,500 full-time employees.

Semiconductor consolidation is the trend of semiconductor companies collaborating in order to come to a practical synergy with the goal of being able to operate in a business model that can sustain profitability.

In the early twenty-first century; foreign investment, government regulations and incentives promoted growth in the Indian electronics industry. The semiconductor industry, which is its most important and resource-intensive sector, profited from the rapid growth in domestic demand. Many industries, including telecommunications, information technology, automotive, engineering, medical electronics, electricity and solar photovoltaic, defense and aerospace, consumer electronics, and appliances, required semiconductors. However, as of 2015, progress was threatened by the talent gap in the Indian sector, since 65 to 70 percent of the market was dependent on imports.

References

- ↑ "FAQs". India Electronics & Semiconductor Association. Archived from the original on 2017-11-20. Retrieved 2013-04-09.

- ↑ Armasu, Lucian (8 May 2015). "Samsung's New $14 Billion Chip Plant To Manufacture DRAM, Processors In 2017". Tom's Hardware. Reuters.

- ↑ Dorsch, Jeff. "Does Moore's Law Still Hold Up?" (PDF). Edavision.com. Archived from the original on 6 May 2006.

{{cite web}}: CS1 maint: bot: original URL status unknown (link) - ↑ Schaller, Bob (1996). "The Origin, Nature, and Implications of 'Moore's Law'". Research.Microsoft.com. Archived from the original on 13 November 2008.

{{cite web}}: CS1 maint: bot: original URL status unknown (link) - ↑ Tremblay, Jean-François (26 June 2006). "Riding On Flat Panels". Chemical & Engineering News. 84 (26): 13–16. doi:10.1021/cen-v084n026.p013.

- 1 2 Ross, Philip E. (2003). "5 Commandments: The rules engineers live by weren't always set in stone". IEEE Spectrum.