A scleroscope is a device used to measure rebound hardness. It consists of a steel ball dropped from a fixed height. The device was invented in 1907. As an improvement on this rough method, the Leeb Rebound Hardness Test, invented in the 1970s, uses the ratio of impact and rebound velocities (as measured by a magnetic inducer) to determine hardness.

A ruler, sometimes called a rule, line gauge, or scale, is an instrument used to make distance measurements whereby a user estimates a distance by reading from a series of markings called "rules" along an edge of the device. Commonly the instrument is rigid and the edge itself is a straightedge which additionally allows one to draw straight lines. Some rulers such as cloth or paper tape measures are non-rigid. Specialty rulers exist that have flexible edges that retain a chosen shape and these find use in sewing, arts, and crafts.

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load compared to the penetration made by a preload. There are different scales, denoted by a single letter, that use different loads or indenters. The result is a dimensionless number noted as HRA, HRB, HRC, etc., where the last letter is the respective Rockwell scale. Higher numbers correspond to harder materials.

A hygrometer is an instrument which measures the humidity of air or some other gas: that is, how much water vapor it contains. Humidity measurement instruments usually rely on measurements of some other quantities such as temperature, pressure, mass, a mechanical or electrical change in a substance as moisture is absorbed. By calibration and calculation, these measured quantities can lead to a measurement of humidity. Modern electronic devices use the temperature of condensation, or they sense changes in electrical capacitance or resistance to measure humidity differences. A crude hygrometer was invented by Leonardo da Vinci in 1480. Major leaps came forward during the 1600s; Francesco Folli invented a more practical version of the device, while Robert Hooke improved a number of meteorological devices including the hygrometer. A more modern version was created by Swiss polymath Johann Heinrich Lambert in 1755. Later, in the year 1783, Swiss physicist and Geologist Horace Bénédict de Saussure invented the first hygrometer using human hair to measure humidity.

The Brinell scale characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science.

A jewel bearing is a plain bearing in which a metal spindle turns in a jewel-lined pivot hole. The hole is typically shaped like a torus and is slightly larger than the shaft diameter. The jewels are typically made from the mineral corundum, usually either synthetic sapphire or synthetic ruby. Jewel bearings are used in precision instruments where low friction, long life, and dimensional accuracy are important. Their main use is in mechanical watches.

The sclerometer, also known as the Turner-sclerometer, is an instrument used by metallurgists, material scientists and mineralogists to measure the scratch hardness of materials. It was invented in 1896 by Thomas Turner (1861–1951), the first Professor of metallurgy in Britain, at the University of Birmingham.

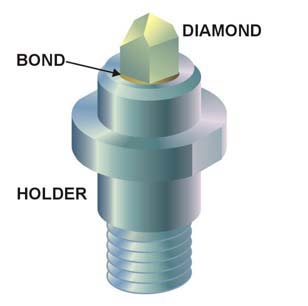

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of hardness, is to observe a material's ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH). The hardness number can be converted into units of pascals, but should not be confused with pressure, which uses the same units. The hardness number is determined by the load over the surface area of the indentation and not the area normal to the force, and is therefore not pressure.

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on a macroscopic or microscopic scale.

The hardenability of a metal alloy is the depth to which a material is hardened after putting it through a heat treatment process. It should not be confused with hardness, which is a measure of a sample's resistance to indentation or scratching. It is an important property for welding, since it is inversely proportional to weldability, that is, the ease of welding a material.

The Knoop hardness test is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed into the polished surface of the test material with a known load, for a specified dwell time, and the resulting indentation is measured using a microscope. The geometry of this indenter is an extended pyramid with the length to width ratio being 7:1 and respective face angles are 172 degrees for the long edge and 130 degrees for the short edge. The depth of the indentation can be approximated as 1/30 of the long dimension. The Knoop hardness HK or KHN is then given by the formula:

In materials science, hardness is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion. In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as sodium and metallic tin, or wood and common plastics. Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, hardness can be measured in different ways, such as scratch hardness, indentation hardness, and rebound hardness. Hardness is dependent on ductility, elastic stiffness, plasticity, strain, strength, toughness, viscoelasticity, and viscosity. Common examples of hard matter are ceramics, concrete, certain metals, and superhard materials, which can be contrasted with soft matter.

A Schmidt hammer, also known as a Swiss hammer or a rebound hammer or concrete hammer test, is a device to measure the elastic properties or strength of concrete or rock, mainly surface hardness and penetration resistance. It was invented by Ernst Heinrich Wilhelm Schmidt, a Swiss engineer.

Nanoindentation, also called instrumented indentation testing, is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material.

The Shore durometer is a device for measuring the hardness of a material, typically of polymers.

A Berkovich tip is a type of nanoindenter tip used for testing the indentation hardness of a material. It is a three-sided pyramid which is geometrically self-similar. The popular Berkovich now has a very flat profile, with a total included angle of 142.3 degrees and a half angle of 65.27 degrees, measured from the axis to one of the pyramid flats. This Berkovich tip has the same projected area-to-depth ratio as a Vickers indenter. The original tip shape was invented by Russian scientist E.S. Berkovich in the USSR c. 1950, which has a half angle of 65.03 degrees.

A Persoz pendulum is a device used for measuring hardness of materials. The instrument consists of a pendulum which is free to swing on two balls resting on a coated test panel. The pendulum hardness test is based on the principle that the amplitude of the pendulum's oscillation will decrease more quickly when supported on a softer surface. The hardness of any given coating is given by the number of oscillations made by the pendulum within the specified limits of amplitude determined by accurately positioned photo sensors. An electronic counter records the number of swings made by the pendulum

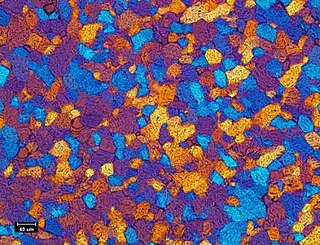

Ceramography is the art and science of preparation, examination and evaluation of ceramic microstructures. Ceramography can be thought of as the metallography of ceramics. The microstructure is the structure level of approximately 0.1 to 100 µm, between the minimum wavelength of visible light and the resolution limit of the naked eye. The microstructure includes most grains, secondary phases, grain boundaries, pores, micro-cracks and hardness microindentations. Most bulk mechanical, optical, thermal, electrical and magnetic properties are significantly affected by the microstructure. The fabrication method and process conditions are generally indicated by the microstructure. The root cause of many ceramic failures is evident in the microstructure. Ceramography is part of the broader field of materialography, which includes all the microscopic techniques of material analysis, such as metallography, petrography and plastography. Ceramography is usually reserved for high-performance ceramics for industrial applications, such as 85–99.9% alumina (Al2O3) in Fig. 1, zirconia (ZrO2), silicon carbide (SiC), silicon nitride (Si3N4), and ceramic-matrix composites. It is seldom used on whiteware ceramics such as sanitaryware, wall tiles and dishware.

The Meyer hardness test is a hardness test based upon projected area of an impression. The hardness, , is defined as the maximum load, divided by the projected area of the indent, .

A nanoindenter is the main component for indentation hardness tests used in nanoindentation. Since the mid-1970s nanoindentation has become the primary method for measuring and testing very small volumes of mechanical properties. Nanoindentation, also called depth sensing indentation or instrumented indentation, gained popularity with the development of machines that could record small load and displacement with high accuracy and precision. The load displacement data can be used to determine modulus of elasticity, hardness, yield strength, fracture toughness, scratch hardness and wear properties.

The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces.