Related Research Articles

Spicules are any of various small needle-like anatomical structures occurring in organisms

A test tube, also known as a culture tube or sample tube, is a common piece of laboratory glassware consisting of a finger-like length of glass or clear plastic tubing, open at the top and closed at the bottom.

Fiberglass or fibreglass is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic.

Corning Incorporated is an American multinational technology company that specializes in specialty glass, ceramics, and related materials and technologies including advanced optics, primarily for industrial and scientific applications. The company was named Corning Glass Works until 1989. Corning divested its consumer product lines in 1998 by selling the Corning Consumer Products Company subsidiary to Borden.

The Venus' flower basket is a glass sponge in the phylum Porifera. It is a marine sponge found in the deep waters of the Pacific ocean, usually at depths below 500 meters. Like other sponges, they feed by filtering sea water to capture plankton and marine snow. Similar to other glass sponges, they build their skeletons out of silica, which forms a unique lattice structure of spicules. The sponges are usually between 10 cm and 30 cm tall, and their bodies act as refuge for their mutualist shrimp partners. This body structure is of great interest in materials science as the optical and mechanical properties are in some ways superior to man-made materials. Little is known regarding their reproduction habits, however fluid dynamics of their body structure likely influence reproduction and it is hypothesized that they may be hermaphroditic.

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies and casting dies which are not. Like molds, dies are generally customized to the item they are used to create.

A cermet is a composite material composed of ceramic and metal materials.

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process.

In solar physics, a spicule, also known as a fibril or mottle, is a dynamic jet of plasma in the Sun's chromosphere about 300 km in diameter. They move upwards with speeds between 15 and 110 km/s from the photosphere and last a few minutes each. They were discovered in 1877 by Angelo Secchi, but the physical mechanism that generates them is still hotly debated.

Maxell, Ltd., commonly known as Maxell, is a Japanese company that manufactures consumer electronics.

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion, making them more resistant to thermal shock than any other common glass. Such glass is subjected to less thermal stress and can withstand temperature differentials without fracturing of about 165 °C (300 °F). It is commonly used for the construction of reagent bottles and flasks as well as lighting, electronics, and cookware.

Glass tubes are mainly cylindrical hollow-wares. Their special shape combined with the huge variety of glass types, allows the use of glass tubing in many applications. For example, laboratory glassware, lighting applications, solar thermal systems and pharmaceutical packaging to name the largest.

Drawing is a metalworking process that uses tensile forces to elongate metal, glass, or plastic. As the material is drawn (pulled), it stretches and becomes thinner, achieving a desired shape and thickness. Drawing is classified into two types: sheet metal drawing and wire, bar, and tube drawing. Sheet metal drawing is defined as a plastic deformation over a curved axis. For wire, bar, and tube drawing, the starting stock is drawn through a die to reduce its diameter and increase its length. Drawing is usually performed at room temperature, thus classified as a cold working process; however, drawing may also be performed at higher temperatures to hot work large wires, rods, or hollow tubes in order to reduce forces.

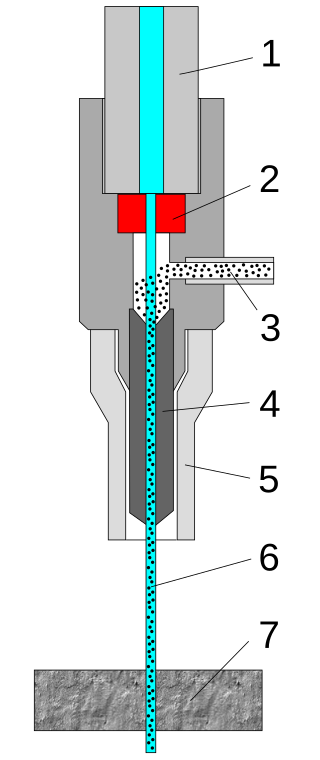

A water jet cutter, also known as a water jet or waterjet, is an industrial tool capable of cutting a wide variety of materials using an extremely high-pressure jet of water, or a mixture of water and an abrasive substance. The term abrasive jet refers specifically to the use of a mixture of water and an abrasive to cut hard materials such as metal, stone or glass, while the terms pure waterjet and water-only cutting refer to waterjet cutting without the use of added abrasives, often used for softer materials such as wood or rubber.

Glass bead making has long traditions, with the oldest known beads dating over 3,000 years. Glass beads have been dated back to at least Roman times. Perhaps the earliest glass-like beads were Egyptian faience beads, a form of clay bead with a self-forming vitreous coating. Glass beads are significant in archaeology because the presence of glass beads often indicate that there was trade and that the bead making technology was being spread. In addition, the composition of the glass beads could be analyzed and help archaeologists understand the sources of the beads.

Knife making is the process of manufacturing a knife by any one or a combination of processes: stock removal, forging to shape, welded lamination or investment cast. Typical metals used come from the carbon steel, tool, or stainless steel families. Primitive knives have been made from bronze, copper, brass, iron, obsidian, and flint.

A vial is a small glass or plastic vessel or bottle, often used to store medication in the form of liquids, powders, or capsules. They can also be used as scientific sample vessels; for instance, in autosampler devices in analytical chromatography. Vial-like glass containers date back to classical antiquity; modern vials are often made of plastics such as polypropylene. There are different types of vials such as a single dose vial and multi-dose vials often used for medications. The single dose vial is only used once whereas a multi-dose vial can be used more than once. The CDC sets specific guidelines on multi-dose vials.

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature. Such processes are contrasted with hot working techniques like hot rolling, forging, welding, etc. The same or similar terms are used in glassmaking for the equivalents; for example cut glass is made by "cold work", cutting or grinding a formed object.

Glass production involves two main methods – the float glass process that produces sheet glass, and glassblowing that produces bottles and other containers. It has been done in a variety of ways during the history of glass.