Related Research Articles

Electrostatic discharge (ESD) is a sudden and momentary flow of electric current between two differently-charged objects when brought close together or when the dielectric between them breaks down, often creating a visible spark associated with the static electricity between the objects.

AEC may refer to:

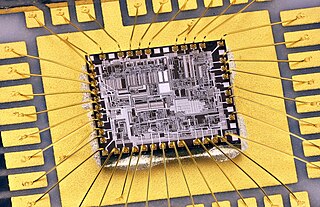

Wire bonding is the method of making interconnections between an integrated circuit (IC) or other semiconductor device and its packaging during semiconductor device fabrication. Although less common, wire bonding can be used to connect an IC to other electronics or to connect from one printed circuit board (PCB) to another. Wire bonding is generally considered the most cost-effective and flexible interconnect technology and is used to assemble the vast majority of semiconductor packages. Wire bonding can be used at frequencies above 100 GHz.

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing. NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art. Innovations in the field of nondestructive testing have had a profound impact on medical imaging, including on echocardiography, medical ultrasonography, and digital radiography.

Automotive engineering, along with aerospace engineering and naval architecture, is a branch of vehicle engineering, incorporating elements of mechanical, electrical, electronic, software, and safety engineering as applied to the design, manufacture and operation of motorcycles, automobiles, and trucks and their respective engineering subsystems. It also includes modification of vehicles. Manufacturing domain deals with the creation and assembling the whole parts of automobiles is also included in it. The automotive engineering field is research intensive and involves direct application of mathematical models and formulas. The study of automotive engineering is to design, develop, fabricate, and test vehicles or vehicle components from the concept stage to production stage. Production, development, and manufacturing are the three major functions in this field.

Failure mode and effects analysis is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effects. For each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet. There are numerous variations of such worksheets. An FMEA can be a qualitative analysis, but may be put on a quantitative basis when mathematical failure rate models are combined with a statistical failure mode ratio database. It was one of the first highly structured, systematic techniques for failure analysis. It was developed by reliability engineers in the late 1950s to study problems that might arise from malfunctions of military systems. An FMEA is often the first step of a system reliability study.

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time.

Environmental stress screening (ESS) refers to the process of exposing a newly manufactured or repaired product or component to stresses such as thermal cycling and vibration in order to force latent defects to manifest themselves by permanent or catastrophic failure during the screening process. The surviving population, upon completion of screening, can be assumed to have a higher reliability than a similar unscreened population.

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards (PCBs). Conformal coatings are typically applied at 25–250 μm to the electronic circuitry and provide protection against moisture and other harsher conditions.

A cable harness, also known as a wire harness, wiring harness, cable assembly, wiring assembly or wiring loom, is an assembly of electrical cables or wires which transmit signals or electrical power. The cables are bound together by a durable material such as rubber, vinyl, electrical tape, conduit, a weave of extruded string, or a combination thereof.

The Standardization Administration of China is the standards organization authorized by the State Council of China to exercise administrative responsibilities by undertaking unified management, supervision and overall coordination of standardization work in China. The SAC represents China within the International Organization for Standardization (ISO), the International Electrotechnical Commission (IEC) and other international and regional standardization organizations; the SAC is responsible for organizing the activities of the Chinese National Committee for ISO and IEC; the SAC approves and organizes the implementation of international cooperation and the exchange of projects on standardization.

Reliability of a semiconductor device is the ability of the device to perform its intended function during the life of the device in the field.

The Motor Industry Software Reliability Association (MISRA) is an organization that produces guidelines for the software developed for electronic components used in the automotive industry. It is a collaboration between vehicle manufacturers, component suppliers and engineering consultancies. In 2021, the loose consortium restructured as The MISRA Consortium Limited.

Association for Standardization of Automation and Measuring Systems or ASAM is an incorporated association under German law. Its members are primarily international car manufacturers, suppliers and engineering service providers from the automotive industry. The association coordinates the development of technical standards, which are developed by working groups composed of experts from its member companies. ASAM pursues the vision that the tools of a development process chain can be freely interconnected and allow a seamless exchange of data. The standards define protocols, data models, file formats and application programming interfaces (APIs) for the use in the development and testing of automotive electronic control units. A large amount of popular tools in the areas of simulation, measurement, calibration and test automation are compliant to ASAM standards. Compliance shall guarantee interoperability of tools from different vendors, allow data exchange without the need for converters, and facilitate the exchange of unambiguous specification between customers and suppliers.

ISO 26262, titled "Road vehicles – Functional safety", is an international standard for functional safety of electrical and/or electronic systems that are installed in serial production road vehicles, defined by the International Organization for Standardization (ISO) in 2011, and revised in 2018.

NSF is a product testing, inspection, certification organization with headquarters in Ann Arbor, Michigan. NSF also offers consulting and training services worldwide.

Robustness validation is a skills strategy with which the Robustness of a product to the loading conditions of a real application is proven and targeted statements about risks and reliability can be made. This strategy is particularly for use in the automotive industry however could be applied to any industry where high levels of reliability are required

High-temperature operating life (HTOL) is a reliability test applied to integrated circuits (ICs) to determine their intrinsic reliability. This test stresses the IC at an elevated temperature, high voltage and dynamic operation for a predefined period of time. The IC is usually monitored under stress and tested at intermediate intervals. This reliability stress test is sometimes referred to as a lifetime test, device life test or extended burn in test and is used to trigger potential failure modes and assess IC lifetime.

The OPEN Alliance is a non-profit, special interest group (SIG) of mainly automotive industry and technology providers collaborating to encourage wide scale adoption of Ethernet-based communication as the standard in automotive networking applications.

Standardisation Testing and Quality Certification (STQC) Directorate, established in 1980, is an authoritative body offering quality assurance services to IT and Electronics domains.