Steelmaking is the process for producing steel from iron ore and scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon are removed from the raw iron, and alloying elements such as manganese, nickel, chromium and vanadium are added to produce different grades of steel. Limiting dissolved gases such as nitrogen and oxygen, and entrained impurities in the steel is also important to ensure the quality of the products cast from the liquid steel.

The Homestead strike, also known as the Homestead Steel strike, Pinkerton rebellion, or Homestead massacre, was an industrial lockout and strike which began on July 1, 1892, culminating in a battle between strikers and private security agents on July 6, 1892. The battle was one of the most violent disputes in U.S. labor history, third behind the Ludlow Massacre and the Battle of Blair Mountain. The dispute occurred at the Homestead Steel Works in the Pittsburgh area town of Homestead, Pennsylvania, between the Amalgamated Association of Iron and Steel Workers and the Carnegie Steel Company. The final result was a major defeat for the union of strikers and a setback for their efforts to unionize steelworkers.

An ironworks or iron works is a building or site where iron is smelted and where heavy iron and steel products are made. The term is both singular and plural, i.e. the singular of ironworks is ironworks.

Carnegie Steel Company was a steel-producing company primarily created by Andrew Carnegie and several close associates, to manage businesses at steel mills in the Pittsburgh, Pennsylvania area in the late 19th century. The company formed in 1892 and was subsequently sold in 1901 in one of the largest ever business transactions of the early 20th century, to become the major component of the United States Steel Corporation. The subsequent sale made Carnegie one of the richest men in history.

Puddling was one step in one of the most important processes of making the first appreciable volumes of high-grade bar iron during the Industrial Revolution. In the original puddling technique, molten iron in a reverberatory furnace was stirred with rods, which were consumed in the process. It was one of the first processes for making bar iron without charcoal in Europe, although much earlier coal-based processes had existed in China. Eventually, the furnace would be used to make small quantities of specialty steels.

The Colorado Fuel and Iron Company (CF&I) was a large steel concentration. By 1903, it was mainly owned and controlled by John D. Rockefeller and Jay Gould's financial heirs. While it came to control many plants throughout the country, its main plant was a steel mill on the south side of Pueblo, Colorado and was the city's main industry for most of its history. From 1901 to 1912, Colorado Fuel and Iron was one of the Dow Jones Industrials. The steel-market crash of 1982 lead to the decline of the company. After going through several bankruptcies, the company was acquired by Oregon Steel Mills in 1993, and changed its name to Rocky Mountain Steel Mills. In January 2007, along with the rest of Oregon Steel's holdings, was acquired by EVRAZ Group, a Russian steel corporation, for $2.3 billion.

The steel strike of 1919 was an attempt by the weakened Amalgamated Association of Iron, Steel and Tin Workers (AA) to organize the United States steel industry in the wake of World War I. The strike began on September 22, 1919, and collapsed on January 8, 1920.

The Edgar Thomson Steel Works is a steel mill in the Pittsburgh area communities of Braddock and North Braddock, Pennsylvania, United States. It has been active since 1872. It is currently owned by U.S. Steel and is known as Mon Valley Works – Edgar Thomson Plant on its official website.

The history of the modern steel industry began in the late 1850s; steel has became a staple of the world's industrial economy. This article is intended only to address the business, economic and social dimensions of the industry, since the bulk production of steel began as a result of Henry Bessemer's development of the Bessemer converter, in 1857. Previously, steel was very expensive to produce, and only used in small, expensive items, such as knives, swords and armor.

The Lackawanna Steel Company was an American steel manufacturing company that existed as an independent company from 1840 to 1922, and as a subsidiary of the Bethlehem Steel company from 1922 to 1983. Founded by the Scranton family, it was once the second-largest steel company in the world. Scranton, Pennsylvania developed around the company's original location. When the company moved to a suburb of Buffalo, New York, in 1902, it stimulated the founding of the city of Lackawanna.

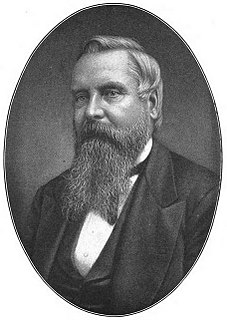

Eber Brock Ward was an American iron and steel manufacturer and shipbuilder. He was known as the "steamship king of the Great Lakes" and as the "first of the iron kings." Ward became Detroit's first millionaire. He was the wealthiest man in the Midwest, in his time, due to his steel factories.

The Illinois Steel Company was an American steel producer with five plants in Illinois and Wisconsin. Founded through a consolidation in 1889, Illinois Steel grew to become the largest steel producer in the United States. In 1898, several other steel and transportation companies were merged into it to form the Federal Steel Company, itself merged into U.S. Steel in 1901.

The Bourne-Fuller Company in Cleveland, Ohio, was one of three constituent companies that formed the Republic Steel Corporation in 1930. The other companies were the Central Alloy Company and Republic Iron and Steel Company. The principal stockholder of Republic was Cyrus Eaton, a well-known financier who made a fortune, in part, through Republic Steel.

The US iron and steel industry has paralleled the industry in other countries in technological developments. In the 1800s, the US switched from charcoal to coke in ore smelting, adopted the Bessemer process, and saw the rise of very large integrated steel mills. In the 20th century, the US industry successively adopted the open hearth furnace, then the basic oxygen steelmaking process. Since the American industry peaked in the 1940s and 1950s, the US industry has shifted to small mini-mills and specialty mills, using iron and steel scrap as feedstock, rather than iron ore.

The Société des aciéries de Longwy was a steelworks located in Longwy, Meurthe-et-Moselle, France.

Union–Miles Park is a city planning area on the East Side of Cleveland, Ohio, in the United States. The neighborhood draws its name from Union Avenue, and Miles Park in its far southwest corner.

Samuel Augustus Fuller Sr. was an American steel industry executive during the Gilded Age in the United States. A resident of Cleveland, Ohio, he founded the Union Iron Works and Condit-Fuller & Co., which later merged to become the Bourne-Fuller Company.