A tradesperson or tradesman/woman is a skilled worker that specialises in a particular trade. Tradesperson (tradesman/woman) usually gain their skills through work experience, on-the-job training, an apprenticeship program or formal education.

A welder is a person or equipment that fuses materials together. The term welder refers to the operator, the machine is referred to as the welding power supply. The materials to be joined can be metals or varieties of plastic or polymer. Welders typically have to have good dexterity and attention to detail, as well as technical knowledge about the materials being joined and best practices in the field.

Quality assurance (QA) is the term used in both manufacturing and service industries to describe the systematic efforts taken to assure that the product(s) delivered to customer(s) meet with the contractual and other agreed upon performance, design, reliability, and maintainability expectations of that customer. The core purpose of Quality Assurance is to prevent mistakes and defects in the development and production of both manufactured products, such as automobiles and shoes, and delivered services, such as automotive repair and athletic shoe design. Assuring quality and therefore avoiding problems and delays when delivering products or services to customers is what ISO 9000 defines as that "part of quality management focused on providing confidence that quality requirements will be fulfilled". This defect prevention aspect of quality assurance differs from the defect detection aspect of quality control and has been referred to as a shift left since it focuses on quality efforts earlier in product development and production and on avoiding defects in the first place rather than correcting them after the fact.

A machinist is a tradesperson or trained professional who operates machine tools, and has the ability to set up tools such as milling machines, grinders, lathes, and drilling machines.

A millwright is a craftsperson or skilled tradesperson who installs, dismantles, maintains, repairs, reassembles, and moves machinery in factories, power plants, and construction sites.

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material into a specified shape by following coded programmed instructions and without a manual operator directly controlling the machining operation.

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials.

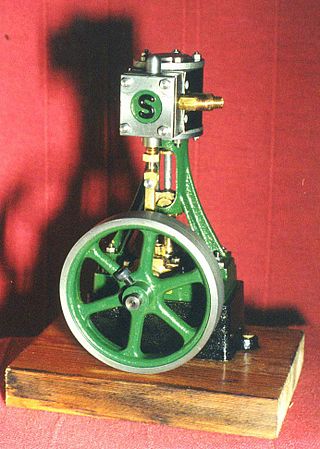

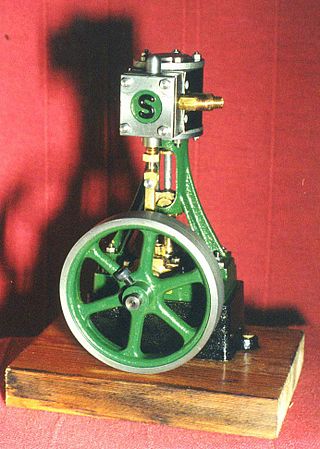

Model engineering is the pursuit of constructing proportionally-scaled miniature working representations of full-sized machines. It is a branch of metalworking with a strong emphasis on artisanry, as opposed to mass production. While now mainly a hobby, in the past it also had commercial and industrial purpose. The term 'model engineering' was in use by 1888. In the United States, the term 'home shop machinist' is often used instead, although arguably the scope of this term is broader.

A boilermaker is a tradesperson who fabricates steels, iron, or copper into boilers and other large containers intended to hold hot gas or liquid, as well as maintains and repairs boilers and boiler systems.

Panel beater or panelbeater is a term used in some Commonwealth countries to describe a person who restores vehicle bodies back to their factory state after having been damaged. In the United States and Canada, the same job is done by an auto body mechanic.

Welder certification, is a process which examines and documents a welder's capability to create welds of acceptable quality following a well defined welding procedure.

Machinist's mate is a rating in the United States Navy's engineering community.

A machine shop or engineering workshop is a room, building, or company where machining, a form of subtractive manufacturing, is done. In a machine shop, machinists use machine tools and cutting tools to make parts, usually of metal or plastic. A machine shop can be a small business or a portion of a factory, whether a toolroom or a production area for manufacturing. The building construction and the layout of the place and equipment vary, and are specific to the shop; for instance, the flooring in one shop may be concrete, or even compacted dirt, and another shop may have asphalt floors. A shop may be air-conditioned or not; but in other shops it may be necessary to maintain a controlled climate. Each shop has its own tools and machinery which differ from other shops in quantity, capability and focus of expertise.

Tool and die makers are highly skilled crafters working in the manufacturing industries. Tool and die makers work primarily in toolroom environments—sometimes literally in one room but more often in an environment with flexible, semipermeable boundaries from production work. They are skilled artisans (craftspeople) who typically learn their trade through a combination of academic coursework and with substantial period of on-the-job training that is functionally an apprenticeship. They make jigs, fixtures, dies, molds, machine tools, cutting tools, gauges, and other tools used in manufacturing processes.

The American Welding Society (AWS) was founded in 1919 as a non-profit organization to advance the science, technology and application of welding and allied joining and cutting processes, including brazing, soldering and thermal spraying.

Industrial training institutes (ITI) and industrial training centers (ITC) is a qualification and are post-secondary schools in India constituted under the Directorate General of Training (DGT), Ministry of Skill Development and Entrepreneurship, Union Government, to provide training in various trades.

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines, and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital.

Hyperbaric welding is the process of extreme welding at elevated pressures, normally underwater. Hyperbaric welding can either take place wet in the water itself or dry inside a specially constructed positive pressure enclosure and hence a dry environment. It is predominantly referred to as "hyperbaric welding" when used in a dry environment, and "underwater welding" when in a wet environment. The applications of hyperbaric welding are diverse—it is often used to repair ships, offshore oil platforms, and pipelines. Steel is the most common material welded.

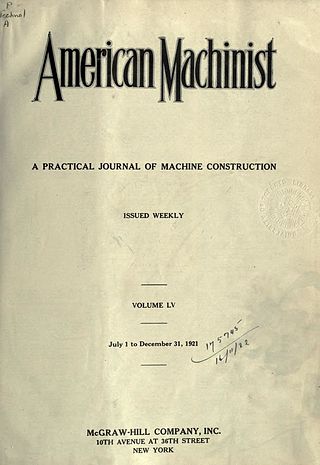

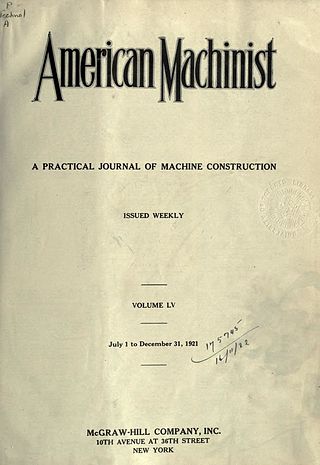

The American Machinist is an American trade magazine of the international machinery industries and most especially their machining aspects. Published since 1877, it was a McGraw-Hill title for over a century before becoming a Penton title in 1988. In 2013 it transitioned from combined print/online publication to online-only.