Related Research Articles

A land mine, or landmine, is an explosive weapon concealed under or camouflaged on the ground, and designed to destroy or disable enemy targets, ranging from combatants to vehicles and tanks, as they pass over or near it.

The M14 mine "Toepopper" is a small anti-personnel land mine first deployed by the United States circa 1955. The M14 mechanism uses a belleville spring to flip a firing pin downwards into a stab detonator when pressure is applied. Once deployed, the M14 is very difficult to detect because it is a minimum metal mine, i.e. most of its components are plastic. Because of this, the design was later modified to ease mine clearance with the addition of a steel washer, glued onto the base of the mine.

The M16 mine is a United States-made bounding anti-personnel mine. It was based on captured plans of the World War II era German S-mine and has similar performance. The mine consists of a cast iron body in a thin steel sleeve. A central fuze well on the top of the mine is normally fitted with a pronged M605 pressure/tension (tripwire) fuze. Sufficient pressure on the prongs or tension on an attached tripwire causes the release of a striker. The freed striker is forced into a percussion cap which ignites a short pyrotechnic delay. The purpose of this delay is to allow the victim to move off the top of the mine, to prevent its upward movement from being blocked. Once the delay has burned through, a 4.5-gram black powder charge is ignited, which launches the inner iron body of the mine up into the air. The charge also ignites a second pair of pyrotechnic delays.

The PMD-6, PMD-7 and PMD-57 series mines are Soviet Union blast-type anti-personnel mines that consist of a wooden box with a hinged lid with a slot cut into it. The slot presses down against a retaining pin, which holds back the striker. When sufficient pressure is applied to the lid of the box the retaining pin moves, allowing the striker to hit the detonator. The mines typically have an operating pressure of 1 to 10 kg.

Anti-personnel landmines (APLs) are a form of mine designed for use against humans, as opposed to anti-tank mines, which target vehicles. APLs are classified into: blast mines and fragmentation mines; the latter may or may not be a bounding mine.

The PROM-1 is a Yugoslavian manufactured bounding anti-personnel mine. It consists of a cylindrical body with a pronged fuze inserted into the top of the mine. It is broadly similar in operation to the German S-mine.

The PMN series of blast anti-personnel mines were designed and manufactured in the Soviet Union. They are one of the most widely used and commonly found devices during demining operations. They are sometimes nicknamed "black widow" because of their dark casings.

The VS-50 is a circular plastic-cased anti-personnel blast mine that entered production in 1985. It was formerly made by the now-defunct Valsella Meccanotecnica SpA, an Italian high-tech defence company specialized in area denial systems. The company also the made the Valmara 69, and was one of the first to implement plastic construction for landmines. The VS-50's design is similar to that of the TS-50 and VS-MK2 mines. It is blast resistant and can be used in a minimum metal configuration. Though unlikely to kill, its explosive charge is quite sufficient to destroy the victim's foot, being capable of penetrating 5 mm of mild steel leaving an 80 mm-diameter hole.

The M1, M1A1 and M4 are circular steel cased United States anti-tank blast mines with a distinctive cross shaped pressure spider. The mine was used during the Second World War and a copy produced in Argentina was used during the Falklands War. Another copy is produced in China, there designated as the No. 4 mine. Variants of the mine have also been deployed in Chad and Tunisia.

A minimum metal mine is a land mine that is designed to use the smallest amount of metal possible in its construction. Typically, the only metal components are located inside the fuze mechanism which triggers detonation. Both minimum metal anti-tank and anti-personnel mines exist. Some designs contain virtually no metal at all, e.g., less than a gram. This is achieved by encasing the explosive charge in a plastic, wooden, or glass body, with metallic components limited to the few small parts in the fuze which can not easily be made from other materials, such as the spring, striker tip, and shear pin. Minimum metal mines are extremely difficult to detect using conventional metal mine detectors and usually require modern techniques, such as robotic Multi Period Sensing (MPS) equipment, to identify, but it is still extremely difficult to find non-metallic mines. These techniques are usually restricted to well-funded international mine clearing organizations and major militaries, making minimum metal mines especially pernicious where they are encountered.

A blast resistant mine is a landmine with a fuze which is designed to be insensitive to the shock wave from a nearby explosion. This feature makes it difficult or impossible to clear such mines using explosive minefield breaching techniques. As a result, the process of clearing minefields is slower and more complex. Blast resistance can be achieved in a number of ways.

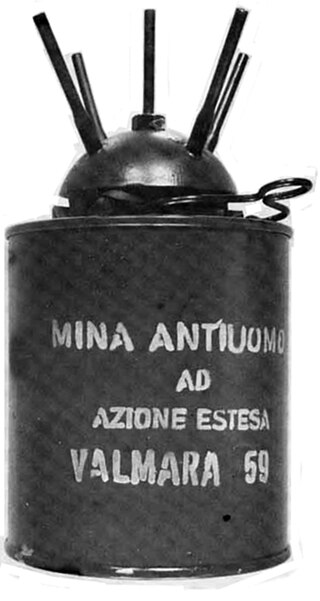

The Valmara 59 is a large cylindrical Italian bounding anti-personnel mine. It is the first in the "Valmara" family of mines produced by Valsella Meccanotecnica, and was followed by the Valmara 69 and VS-JAP. The mine's body is plastic with a distinctive five-pronged metal head. The central prong has a hole, to allow the threading a trip wire. The inner body of the mine has a main charge surrounded with approximately 1,000 steel cubes, below which is a steel wire connecting it to the base of the mine. When the mine is triggered a small charge launches the mine into the air approximately 45 cm before the steel wire is pulled taut, the jolt of which pulls a striker into the detonator. A secondary time fuse triggers the mine after three seconds if it has not detonated after being triggered.

The NR-413 is a Belgian trip wire activated anti-personnel stake mine. The main body of the mine is wine bottle shaped, with an NR 410 tripwire fuse screwed into a fuse well on the top of the mine. Under the fuse well is a detonator and a row of booster pellets. Wrapped around the detonator and booster pellets is the main charge. An internally square cross-sectioned steel wire is coiled around the outside of the mine, which give a fragmentation effect. The mine produces 600 fragments with a velocity of approximately 1,660 metres per second. It has an effective range of around 15 metres. A variant is produced with a cast steel fragmentation jacket.

The P-25 is a plastic cased Italian anti-personnel stake mine. It was developed along with the larger P-40 mine in the late 1970s by Misar SpA and entered production in 1978. The mine consists of a plastic cylinder with a fuse protruding from the top. The mine can either be stake mounted or buried, although it was designed to be stake mounted. Pull pressure on the tripwire results in the fuse head tilting sideways, releasing a striker into the detonator assembly.

An anti-handling device is an attachment to or an integral part of a landmine or other munition such as some fuze types found in general-purpose air-dropped bombs, cluster bombs and sea mines. It is designed to prevent tampering or disabling, or to target bomb disposal personnel. When the protected device is disturbed, it detonates, killing or injuring anyone within the blast area. There is a strong functional overlap of booby traps and anti-handling devices.

The TM-41 was a circular, metal-cased Soviet anti-tank landmine used during the Second World War. The mines case consisted of a short cylinder with the entire top surface being used as a pressure plate. The mine has a carrying handle on the side of the mine. It was normally painted olive drab and was broadly similar to the larger, later, TM-44 mine.

The TM-44 was a circular metal-cased Soviet anti-tank landmine used during the Second World War. The mine's case consisted of a short cylinder with the entire top surface being used as a pressure plate. The mine was normally painted olive drab and was broadly similar to the earlier, smaller, TM-41 mine.

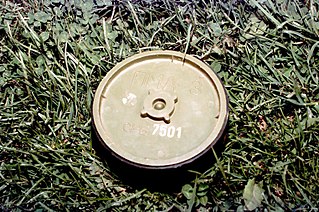

The TS-50 is a 90 mm (3.5 in) diameter circular Italian blast resistant minimum metal anti-personnel mine designed and produced by Valsella Meccanotecnica (Italy).

The PMA-3 is a Yugoslavian blast resistant minimum metal anti-personnel mine. It is circular, consisting of a plastic upper and lower half joined together by a rubber cover. A safety collar is normally wrapped around the outside of the mine, preventing the upper half of the mine tilting when in transit. Once deployed the safety collar is removed. Sufficient pressure on the top surface of the mine causes it to tilt. The tilting drives a pin through a friction sensitive pyrotechnic compound, which fires the detonator and then the main explosive charge.

In military munitions, a fuze is the part of the device that initiates function. In some applications, such as torpedoes, a fuze may be identified by function as the exploder. The relative complexity of even the earliest fuze designs can be seen in cutaway diagrams.