Electrochemistry is the branch of physical chemistry that studies the relationship between electricity, as a measurable and quantitative phenomenon, and identifiable chemical change, with either electricity considered an outcome of a particular chemical change or vice versa. These reactions involve electric charges moving between electrodes and an electrolyte. Thus electrochemistry deals with the interaction between electrical energy and chemical change.

An ore is an occurrence of rock or sediment that contains sufficient minerals with economically important elements, typically metals, that can be economically extracted from the deposit. The ores are extracted from the earth through mining; they are then refined to extract the valuable element, or elements.

In chemistry and manufacturing, electrolysis is a technique that uses a direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of elements from naturally occurring sources such as ores using an electrolytic cell. The voltage that is needed for electrolysis to occur is called the decomposition potential.

Extractive metallurgy is a branch of metallurgical engineering wherein process and methods of extraction of metals from their natural mineral deposits are studied. The field is a materials science, covering all aspects of the types of ore, washing, concentration, separation, chemical processes and extraction of pure metal and their alloying to suit various applications, sometimes for direct use as a finished product, but more often in a form that requires further working to achieve the given properties to suit the applications.

Potassium chloride (KCl) is a metal halide salt composed of potassium and chlorine. It is odorless and has a white or colorless vitreous crystal appearance. The solid dissolves readily in water and its solutions have a salt-like taste. KCl is used as a fertilizer, in medicine, in scientific applications, and in food processing, where it may be known as E number additive E508.

An electrolytic cell is an electrochemical cell that drives a non-spontaneous redox reaction through the application of electrical energy. They are often used to decompose chemical compounds, in a process called electrolysis—the Greek word lysis means to break up.

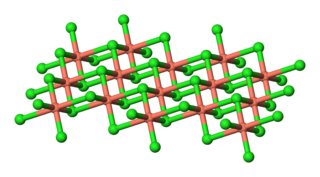

Iron(III) chloride, also called ferric chloride, is an industrial scale commodity chemical compound, with the formula FeCl3 and with iron in the +3 oxidation state. The colour of iron(III) chloride crystals depends on the viewing angle: by reflected light the crystals appear dark green, but by transmitted light they appear purple-red. Anhydrous iron(III) chloride is deliquescent, forming hydrated hydrogen chloride mists in moist air. It is rarely observed in its natural form, the mineral molysite, known mainly from some fumaroles.

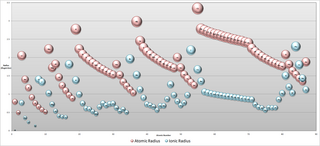

In chemistry, a reactivity series (or activity series) is an empirical, calculated, and structurally analytical progression of a series of metals, arranged by their "reactivity" from highest to lowest. It is used to summarize information about the reactions of metals with acids and water, double displacement reactions and the extraction of metals from their ores.

Copper extraction refers to the methods used to obtaining copper from its ores. The conversion of copper consists of a series of chemical, physical, and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.

The electrolysis of brine is an industrial process for the electrolysis of sodium chloride. It is the technology used to produce chlorine and sodium hydroxide, which are commodity chemicals required by industry. 35 million tons of chlorine were prepared by this process in 1987. Industrial scale production began in 1892.

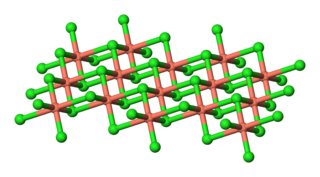

Copper(II) chloride is the chemical compound with the chemical formula CuCl2. This is a light brown solid, which slowly absorbs moisture to form a blue-green dihydrate. The copper(II) chlorides are some of the most common copper(II) compounds, after copper sulfate.

The Kroll process is a pyrometallurgical industrial process used to produce metallic titanium. It was invented in 1940 by William J. Kroll in Luxembourg. After moving to the United States, Kroll further developed the method for the production of zirconium. The Kroll process replaced the Hunter process for almost all commercial production.

Hydrometallurgy is a method for obtaining metals from their ores. It is a technique within the field of extractive metallurgy involving the use of aqueous chemistry for the recovery of metals from ores, concentrates, and recycled or residual materials. Metal chemical processing techniques that complement hydrometallurgy are pyrometallurgy, vapour metallurgy and molten salt electrometallurgy. Hydrometallurgy is typically divided into three general areas:

The FFC Cambridge Process is an electrochemical method in which solid metal compounds, particularly oxides, are cathodically reduced to the respective metals or alloys in molten salts. It is thought that this process will eventually be capable of producing metals or alloys more efficiently than by current conventional processes, such as titanium by the Kroll process.

Tin(II) chloride, also known as stannous chloride, is a white crystalline solid with the formula SnCl2. It forms a stable dihydrate, but aqueous solutions tend to undergo hydrolysis, particularly if hot. SnCl2 is widely used as a reducing agent (in acid solution), and in electrolytic baths for tin-plating. Tin(II) chloride should not be confused with the other chloride of tin; tin(IV) chloride or stannic chloride (SnCl4).

In coordination chemistry, metal ammine complexes are metal complexes containing at least one ammonia (NH3) ligand. "Ammine" is spelled this way due to historical reasons; in contrast, alkyl or aryl bearing ligands are spelt with a single "m". Almost all metal ions bind ammonia as a ligand, but the most prevalent examples of ammine complexes are for Cr(III), Co(III), Ni(II), Cu(II) as well as several platinum group metals.

The Downs' process is an electrochemical method for the commercial preparation of metallic sodium, in which molten NaCl is electrolyzed in a special apparatus called the Downs cell. The Downs cell was invented in 1922 by the American chemist James Cloyd Downs (1885–1957).

Bronze disease is the irreversible and nearly inexorable corrosion process occurring when chlorides come into contact with bronze or other copper-bearing alloys. It occurs as a dark green or a lighter fuzzy green coating on copper, bronze, and other copper-bearing alloys generally due either to contamination by salt water or after burial in dirt. If not treated, complete destruction of the affected artifact is possible. Transfer of chlorides from the contaminated artifact to other artifacts can spread the condition.

Non-ferrous extractive metallurgy is one of the two branches of extractive metallurgy which pertains to the processes of reducing valuable, non-iron metals from ores or raw material. Metals like zinc, copper, lead, aluminium as well as rare and noble metals are of particular interest in this field, while the more common metal, iron, is considered a major impurity. Like ferrous extraction, non-ferrous extraction primarily focuses on the economic optimization of extraction processes in separating qualitatively and quantitatively marketable metals from its impurities (gangue).