A symplectite (or symplektite) is a material texture: a micrometre-scale or submicrometre-scale intergrowth of two or more crystals. Symplectites form from the breakdown of unstable phases, and may be composed of minerals, ceramics, or metals. Fundamentally, their formation is the result of slow grain-boundary diffusion relative to interface propagation rate. [1] [2] [3]

If a material undergoes a change in temperature, pressure or other physical conditions (e.g., fluid composition or activity), one or more phases may be rendered unstable and recrystallize to more stable constituents. If the recrystallized minerals are fine grained and intergrown, this may be termed a symplectite. A cellular precipitation reaction, in which a reactant phase decomposes to a product phase with the same structure as the parent phase and a second phase with a different structure, can form a symplectite. [4] Eutectoid reactions, involving the breakdown of a single phase to two or more phases, neither of which is structurally or compositionally identical to the parent phase, can also form symplectites. [5]

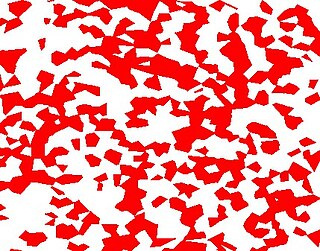

Symplectites may be formed by reaction between adjacent phases or to decomposition of a single phase. The intergrown phases may be planar or rodlike, depending on the volume proportions of the phases, their interfacial free energies, the rate of reaction, the Gibbs free energy change, and the degree of recrystallization. Lamellar symplectites are common in retrogressed eclogite. Kelyphite is a symplectite formed from the decomposition of garnet. [6] Myrmekite is a globular or bulbous symplectite of quartz in plagioclase. [6]

A chemical reaction is a process that leads to the chemical transformation of one set of chemical substances to another. Classically, chemical reactions encompass changes that only involve the positions of electrons in the forming and breaking of chemical bonds between atoms, with no change to the nuclei, and can often be described by a chemical equation. Nuclear chemistry is a sub-discipline of chemistry that involves the chemical reactions of unstable and radioactive elements where both electronic and nuclear changes can occur.

Eclogite is a mafic metamorphic rock. Eclogite forms at pressures greater than those typical of the crust of the Earth. An unusually dense rock, eclogite can play an important role in driving convection within the solid Earth.

Garnets are a group of silicate minerals that have been used since the Bronze Age as gemstones and abrasives.

Examples of symplectites formed in Earth materials include dolomite + calcite, [7] aragonite + calcite, [8] and magnetite + clinopyroxene. [9] Symplectite formation is important in metallurgy: bainite or pearlite formation from the decomposition of austenite, for example. [3]

Bainite is a plate-like microstructure that forms in steels at temperatures of 125–550 °C. First described by E. S. Davenport and Edgar Bain, it is one of the products that may form when austenite is cooled past a temperature where it no longer is thermodynamically stable with respect to ferrite, cementite, or ferrite and cementite. Davenport and Bain originally described the microstructure as being similar in appearance to tempered martensite.

Pearlite is a two-phased, lamellar structure composed of alternating layers of ferrite and cementite that occurs in some steels and cast irons. During slow cooling of an iron-carbon alloy, pearlite forms by a eutectoid reaction as austenite cools below 727 °C (1,341 °F). Pearlite is a microstructure occurring in many common grades of steels.

Austenite, also known as gamma-phase iron (γ-Fe), is a metallic, non-magnetic allotrope of iron or a solid solution of iron, with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of 1000 K (727 °C); other alloys of steel have different eutectoid temperatures. The austenite allotrope is named after Sir William Chandler Roberts-Austen (1843–1902); it exists at room temperature in stainless steel.