The AS/NZS 1200 standard is a joint Australian/New Zealand Standard, for the requirements of pressure equipment which aims to promote safety and uniformity throughout Australia and New Zealand.

The AS/NZS 1200 standard is a joint Australian/New Zealand Standard, for the requirements of pressure equipment which aims to promote safety and uniformity throughout Australia and New Zealand.

This Standard was originally published in 1931 as CB1 - SAA Boiler Code. It was subsequently issued in 1963 and 1967. In 1972, the Standard was issued under the designation AS 1200. The 2nd, 3rd and 4th editions were published in 1978, 1981 and 1988 respectively. In 1994 the Standard was jointed revised and issued under the designation AS/NZS 1200. The latest and 6th edition was published in 2000. [1]

This Standard is a 'parent' document which sets out basic requirements and good practice for the design, materials, manufacture, examination, testing, installation, conformity assessment, commissioning, operation, inspection, maintenance, repair, alteration and disposal of pressure equipment (boilers, pressure vessels and pressure piping) but excluding gas cylinders, blast furnaces, pipelines, fire extinguishers, storage tanks to name a few. [1]

As a 'parent' document this Standard specifies specific requirements to pressure equipment by making reference to a range of Australian, New Zealand and other Standards. [1]

Equipment to be used in Australia or New Zealand must meet the following requirements:

When a selected Standard is used (local or international) as listed in this Standard, it shall be used in its entirety except when compliance with more appropriate requirements of other Standards. Irrespective of the Standard used, the Standard should only be considered as the minimal requirements and not necessarily holistic, therefore judgement needs to be exercised to ensure all relevant matters are covered. [1]

AS/NZS 1200 is a 'parent' Standard that specifies the requirements and Standards specific to pressure equipment. The following provides a sample of some of the Standards applicable to pressure equipment under this Standard. [1]

| Function | Equipment / Action | Standard |

|---|---|---|

| General | General Requirements | AS/NZS 1200 |

| Hazard levels | AS 4343 | |

| Construction | Boilers | AS 1228 |

| Pressure Vessels - General | AS 1210-2010 | |

| Pressure Vessels - Advanced Design | AS 1210-2010 | |

| Pressure Vessels - Cold-stretched Austenitic Stainless Steel Vessels | AS 1210-2010 | |

| Pressure Piping - General | AS 4041 | |

| Manufacturing | AS 4458 | |

| Welding and Brazing Qualifications | AS/NZS 3992 | |

| Examination and Testing | AS 4037 | |

| Installation | AS 3892 | |

| Use | In-service Inspections | AS/NZS 3788 |

| Use | Inspections | AS 3873 |

This section needs to be updated.(March 2015) |

National

Pressure equipment is to be in accordance with AS/NZS 1200 per the Australian Government legislation as stipulated in Regulations 4.05(2)(d) and 4.51 (4)(b) of the Occupational Health and Safety (Safety Standards) Regulations 1994. [2]

Queensland

Some pressure equipment (excluding pressure piping) is regulated in the state of Queensland as per Schedule 4 (13) of the Workplace Health and Safety Regulation 2008. [3] In this Schedule, it refers to certain criteria being met per AS 4343, which scope is to classify hazard levels of pressure equipment to AS/NZS 1200. [4]

New South Wales

Pressure equipment is regulated in the state of New South Wales as per Clause 94 (a) of the Occupational Health and Safety Regulation 2001. [5] This Clause refers to AS 4343 and AS 1210, which are main Standards referenced in the 'parent' Standard AS/NZS 1200. [4] [6]

Pressure equipment is to be in accordance with AS/NZS 1200 under New Zealand legislation as stipulated in section 3.4.1(1) of the Approved Code of Practice (ACOP) for Pressure Equipment (Excluding Boilers). This ACOP supports the requirements of the Health and Safety in Employment (Pressure Equipment, Cranes and Passenger Ropeways) Regulations 1999. [7]

The Occupational Safety and Health Administration is a large regulatory agency of the United States Department of Labor that originally had federal visitorial powers to inspect and examine workplaces. Congress established the agency under the Occupational Safety and Health Act, which President Richard M. Nixon signed into law on December 29, 1970. OSHA's mission is to "assure safe and healthy working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education and assistance". The agency is also charged with enforcing a variety of whistleblower statutes and regulations. OSHA's workplace safety inspections have been shown to reduce injury rates and injury costs without adverse effects to employment, sales, credit ratings or firm survival.

Professional diving is underwater diving where the divers are paid for their work. The procedures are often regulated by legislation and codes of practice as it is an inherently hazardous occupation and the diver works as a member of a team. Due to the dangerous nature of some professional diving operations, specialized equipment such as an on-site hyperbaric chamber and diver-to-surface communication system is often required by law, and the mode of diving for some applications may be regulated.

On commercial products, the letters CE mean that the manufacturer or importer affirms the good's conformity with European health, safety, and environmental protection standards. It is not a quality indicator or a certification mark. The CE marking is required for goods sold in the European Economic Area (EEA), but is also found on products sold elsewhere that have been manufactured to EEA standards.

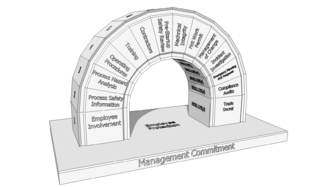

Process safety managementsystem is a regulation promulgated by the U.S. Occupational Safety and Health Administration (OSHA). A process is any activity or combination of activities including any use, storage, manufacturing, handling or the on-site movement of highly hazardous chemicals (HHCs) as defined by OSHA and the Environmental Protection Agency.

In general, compliance means conforming to a rule, such as a specification, policy, standard or law. Regulatory compliance describes the goal that organizations aspire to achieve in their efforts to ensure that they are aware of and take steps to comply with relevant laws, policies, and regulations. Due to the increasing number of regulations and need for operational transparency, organizations are increasingly adopting the use of consolidated and harmonized sets of compliance controls. This approach is used to ensure that all necessary governance requirements can be met without the unnecessary duplication of effort and activity from resources.

The Pressure Equipment Directive (PED) 2014/68/EU of the EU sets out the standards for the design and fabrication of pressure equipment generally over one litre in volume and having a maximum pressure more than 0.5 bar gauge. It also sets the administrative procedures requirements for the "conformity assessment" of pressure equipment, for the free placing on the European market without local legislative barriers. It has been mandatory throughout the EU since 30 May 2002, with 2014 revision fully effective as of 19 July 2016. This is enacted in the UK as the Pressure Equipment Regulations (PER). The set out standards and regulations regarding pressure vessels and boilers safety is also very close to the US standards defined by the American Society of Mechanical Engineers (ASME). This enables most international inspection agencies to provide both verification and certification services to assess compliance to the different pressure equipment directives. From the pressure vessel manufactures PED does not generally require a prior manufacturing permit/certificate/stamp as ASME does.

AS/NZS 3760:2010 is a standard that outlines a testing method and frequency for electrical appliances, created jointly by Standards Australia and Standards New Zealand. It was developed by a committee drawn from both countries.

In common with most of Europe and North America, Australian State Parliaments have responded to workplace illness, injury, and death by enacting legislation regulating workplace hazards. Until the 1970s and 80s, these standards were generally detailed and technical, focusing mainly on prescriptive measures such as specifying machinery guarding measures to be adopted to prevent injury to workers operating dangerous machinery. Beginning in 2008, state and federal regulations were harmonised, giving greater clarity and consistency in the legislation in effect in the various states.

Standards Australia is a standards organisation established in 1922 and is recognised through a Memorandum of Understanding (MoU) with the Australian government as the primary non-government standards development body in Australia. It is a company limited by guarantee. As of 1998, it had 73 members representing groups interested in the development and application of technical standards and related products and services. The MoU recognises Standards Australia as Australia's representative on the International Organization for Standardization (ISO), the International Electrotechnical Commission (IEC) and the Pacific Area Standards Congress (PASC).

The WorkCover Authority of New South Wales was a New South Wales Government agency established in 1989. The agency created regulations to promote productive, healthy and safe workplaces for workers and employers in New South Wales. The agency formed part of the Safety, Return to Work and Support Division established pursuant to the Safety, Return to Work and Support Board Act, 2012 (NSW).

A safety management system (SMS) is designed to manage safety risk in the workplace, occupational safety being defined as the reduction of risk to a level that is as low as is reasonably practicable or ALARP to prevent people getting hurt.

A lone worker (LW) is an employee who performs an activity that is carried out in isolation from other workers without close or direct supervision. Such staff may be exposed to risk because there is no-one to assist them and so a risk assessment may be required. Lone workers are now often supported by cloud-based automated monitoring systems and specialised monitoring call centres - often referred to as an 'Alarm Receiving Centre' or 'ARC' in the UK, or 'Emergency Dispatch Center' or 'EDC' in the US.

The diving supervisor is the professional diving team member who is directly responsible for the diving operation's safety and the management of any incidents or accidents that may occur during the operation; the supervisor is required to be available at the control point of the diving operation for the diving operation's duration, and to manage the planned dive and any contingencies that may occur. Details of competence, requirements, qualifications, registration and formal appointment differ depending on jurisdiction and relevant codes of practice. Diving supervisors are used in commercial diving, military diving, public safety diving and scientific diving operations.

Occupational safety and health (OSH), also commonly referred to as occupational health and safety (OHS), occupational health, or occupational safety, is a multidisciplinary field concerned with the safety, health, and welfare of people at occupation. These terms also refer to the goals of this field, so their use in the sense of this article was originally an abbreviation of occupational safety and health program/department etc.

The Provision and Use of Work Equipment Regulations, commonly abbreviated to PUWER 1998 or simply PUWER, is a statutory instrument of the United Kingdom. It regulates the standards of safety for equipment used in work environments. Its obligations apply to both employers and employees, as well as those who provide equipment for others to use at work.

The AS/NZS 3788 standard is a joint Australian and New Zealand Standard, for the inspection requirements of pressure equipment which aims to promote safety and uniformity throughout Australia and New Zealand.

Media diving is underwater diving in support of the media industries, including the practice of underwater photography and underwater cinematography outside of normal recreational interests. Media diving is often carried out in support of television documentaries, such as the BBC series Planet Earth or movies, with feature films such as Titanic and The Perfect Storm featuring underwater photography or footage. Media divers are normally highly skilled camera operators who use diving as a method to reach their workplace, although some underwater photographers start as recreational divers and move on to make a living from their hobby.

Diving regulations are the stipulations of the delegated legislation regarding the practice of underwater diving. They apply within the national territory and territorial waters of a country. In most cases they apply to occupational diving, but in a few cases also to recreational diving. There are exemptions for recreational diving in some cases where it is recognised as a self-regulated industry. Offshore diving is generally outside the scope of diving regulations, and tends to be self-regulated through voluntary membership of industry organisations.

Canadian pressure laws, Acts, rules & regulations are enforced by provincial and territorial safety authorities. Unlike the United States where licensed professional engineers (PE) may stamp pressure equipment and pressure system/plant drawings in the non-nuclear sectors for construction, in Canada in general a professional engineer (P.ENG) who is not employed by a safety authority does not have that same right to stamp regulated pressure equipment or pressure system drawings for construction, and doing so may result in fines or professional license revocation, or jail time. The pressure safety design registration approval given by safety authority registrars in Canada is called a Canadian Registration Number (CRN). Pressure equipment must be registered in each province or territory where it will be used.