Details

Ernst Abbe (1840–1905), working for Carl Zeiss AG in Jena, Germany in the late 19th century, was the first to develop a laboratory refractometer. These first instruments had built-in thermometers and required circulating water to control instrument and fluid temperatures. They also had adjustments for eliminating the effects of dispersion and analog scales from which the readings were taken.

In the Abbe refractometer the liquid sample is sandwiched into a thin layer between an illuminating prism and a refracting prism. The refracting prism is made of a glass with a high refractive index (e.g., 1.75) and the refractometer is designed to be used with samples having a refractive index smaller than that of the refracting prism. A light source is projected through the illuminating prism, the bottom surface of which is ground (i.e., roughened like a ground-glass joint), so each point on this surface can be thought of as generating light rays traveling in all directions. A detector placed on the back side of the refracting prism would show a light and a dark region.

Over a century after Abbe's work, the usefulness and precision of refractometers has improved, although their principle of operation has changed very little. They are also possibly the easiest device to use for measuring the refractive index of solid samples, such as glass, plastics, and polymer films. Some modern Abbe refractometers use a digital display for measurement, eliminating the need for discerning between small graduations. However, the user still has to adjust the view to get a final reading.

The first truly digital laboratory refractometers began appearing in the late 1970s and early 1980s, and no longer depended on the user's eye to determine the reading. They still required the use of circulating water baths to control instrument and fluid temperature. They did, however, have the ability to electronically compensate for the temperature differences of many fluids where there is a known concentration-to-refractive-index conversion. Most digital laboratory refractometers, while much more accurate and versatile than their analog Abbe counterparts, are incapable of readings on solid samples.

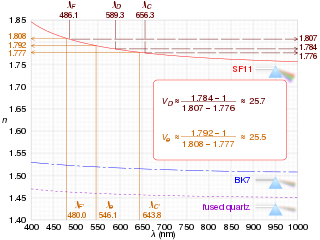

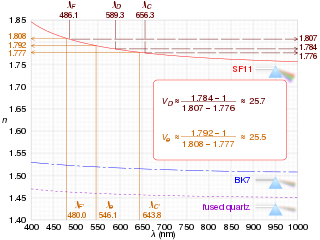

In the late 1990s, Abbe refractometers became available with the capability of measurements at wavelengths other than the standard 589 nanometers. These instruments use special filters to reach the desired wavelength, and can extend measurements well into the near infrared (though a special viewer is required to see the infrared rays). Multi-wavelength Abbe refractometers can be used to easily determine a sample's Abbe number.

The most advanced instruments of today use solid-state Peltier effect devices to heat and cool the instrument and the sample, eliminating the need for an external water bath. The software on most of current instruments offers features such as programmable user-defined scales and a history function that recalls the last several measurements. Several manufacturers offer easily usable controls, with the ability to use from and export readings to a linked computer.

In optics and lens design, the Abbe number, also known as the Vd-number or constringence of a transparent material, is an approximate measure of the material's dispersion, with high values of Vd indicating low dispersion. It is named after Ernst Abbe (1840–1905), the German physicist who defined it. The term Vd-number should not be confused with the normalized frequency in fibers.

In optics, the refractive index of an optical medium is the ratio of the apparent speed of light in the air or vacuum to the speed in the medium. The refractive index determines how much the path of light is bent, or refracted, when entering a material. This is described by Snell's law of refraction, n1 sin θ1 = n2 sin θ2, where θ1 and θ2 are the angle of incidence and angle of refraction, respectively, of a ray crossing the interface between two media with refractive indices n1 and n2. The refractive indices also determine the amount of light that is reflected when reaching the interface, as well as the critical angle for total internal reflection, their intensity and Brewster's angle.

Ultraviolet–visible spectrophotometry refers to absorption spectroscopy or reflectance spectroscopy in part of the ultraviolet and the full, adjacent visible regions of the electromagnetic spectrum. Being relatively inexpensive and easily implemented, this methodology is widely used in diverse applied and fundamental applications. The only requirement is that the sample absorb in the UV-Vis region, i.e. be a chromophore. Absorption spectroscopy is complementary to fluorescence spectroscopy. Parameters of interest, besides the wavelength of measurement, are absorbance (A) or transmittance (%T) or reflectance (%R), and its change with time.

Optics is the branch of physics which involves the behavior and properties of light, including its interactions with matter and the construction of instruments that use or detect it. Optics usually describes the behavior of visible, ultraviolet, and infrared light. Because light is an electromagnetic wave, other forms of electromagnetic radiation such as X-rays, microwaves, and radio waves exhibit similar properties.

Fused quartz, fused silica or quartz glass is a glass consisting of almost pure silica (silicon dioxide, SiO2) in amorphous (non-crystalline) form. This differs from all other commercial glasses, such as soda-lime glass, lead glass, or borosilicate glass, in which other ingredients are added which change the glasses' optical and physical properties, such as lowering the melt temperature, the spectral transmission range, or the mechanical strength. Fused quartz, therefore, has high working and melting temperatures, making it difficult to form and less desirable for most common applications, but is much stronger, more chemically resistant, and exhibits lower thermal expansion, making it more suitable for many specialized uses such as lighting and scientific applications.

Spectrophotometry is a branch of electromagnetic spectroscopy concerned with the quantitative measurement of the reflection or transmission properties of a material as a function of wavelength. Spectrophotometry uses photometers, known as spectrophotometers, that can measure the intensity of a light beam at different wavelengths. Although spectrophotometry is most commonly applied to ultraviolet, visible, and infrared radiation, modern spectrophotometers can interrogate wide swaths of the electromagnetic spectrum, including x-ray, ultraviolet, visible, infrared, or microwave wavelengths.

Ernst Karl Abbe was a German businessman, optical engineer, physicist, and social reformer. Together with Otto Schott and Carl Zeiss, he developed numerous optical instruments. He was also a co-owner of Carl Zeiss AG, a German manufacturer of scientific microscopes, astronomical telescopes, planetariums, and other advanced optical systems.

Refractometry is the analytical method of measuring substances' refractive index in order to, for instance, assess their composition or purity. A refractometer is the instrument used to measure refractive index ("RI"). Although refractometers are best known for measuring liquids, they are also used to measure gases and solids, such as glass and gemstones.

A total internal reflection fluorescence microscope (TIRFM) is a type of microscope with which a thin region of a specimen, usually less than 200 nanometers can be observed.

Degrees Brix is a measure of the dissolved solids in a liquid, and is commonly used to measure dissolved sugar content of a solution. One degree Brix is 1 gram of sucrose in 100 grams of solution and represents the strength of the solution as percentage by mass. If the solution contains dissolved solids other than pure sucrose, then the °Bx only approximates the dissolved solid content. For example, when one adds equal amounts of salt and sugar to equal amounts of water, the degrees of refraction (BRIX) of the salt solution rises faster than the sugar solution. The °Bx is traditionally used in the wine, sugar, carbonated beverage, fruit juice, fresh produce, maple syrup, and honey industries. The °Bx is also used for measuring the concentration of a cutting fluid mixed in water for metalworking processes.

Polarimetry is the measurement and interpretation of the polarization of transverse waves, most notably electromagnetic waves, such as radio or light waves. Typically polarimetry is done on electromagnetic waves that have traveled through or have been reflected, refracted or diffracted by some material in order to characterize that object.

A polarimeter is a scientific instrument used to measure optical rotation: the angle of rotation caused by passing linearly polarized light through an optically active substance.

A refractometer is a laboratory or field device for the measurement of an index of refraction (refractometry). The index of refraction is calculated from the observed refraction angle using Snell's law. For mixtures, the index of refraction then allows the concentration to be determined using mixing rules such as the Gladstone–Dale relation and Lorentz–Lorenz equation.

A traditional handheld refractometer is an analog instrument for measuring a liquid's refractive index. It works on the critical angle principle by which lenses and prisms project a shadow line onto a small glass reticle inside the instrument, which is then viewed by the user through a magnifying eyepiece.

A digital handheld refractometer is an instrument for measuring the refractive index of materials.

Inline process refractometers are a type of refractometer designed for the continuous measurement of a fluid flowing through a pipe or inside a tank. First patented by Carl A. Vossberg Jr. US2807976A - Refractometer US2549402A, these refractometers typically consist of a sensor, placed inline with the fluid flow, coupled to a control box. The control box usually provides a digital readout as well as 4-20 mA analog outputs and relay outputs for controlling pumps and valves. Instead of placing the sensor inline of the process, it can be placed in a bypass, attached by a thin tube.

Friedrich Otto Schott (1851–1935) was a German chemist, glass technologist, and the inventor of borosilicate glass. Schott systematically investigated the relationship between the chemical composition of the glass and its properties. In this way, he solved fundamental problems in glass properties, identifying compositions with optical properties that approach the theoretical limit. Schott's findings were a major advance in the optics for microscopy and optical astronomy. His work has been described as "a watershed in the history of glass composition".

The calculation of glass properties is used to predict glass properties of interest or glass behavior under certain conditions without experimental investigation, based on past data and experience, with the intention to save time, material, financial, and environmental resources, or to gain scientific insight. It was first practised at the end of the 19th century by A. Winkelmann and O. Schott. The combination of several glass models together with other relevant functions can be used for optimization and six sigma procedures. In the form of statistical analysis glass modeling can aid with accreditation of new data, experimental procedures, and measurement institutions.

A differential refractometer (DRI), or refractive index detector is a detector that measures the refractive index of an analyte relative to the solvent. They are often used as detectors for high-performance liquid chromatography and size exclusion chromatography. They are considered to be universal detectors because they can detect anything with a refractive index different from the solvent, but they have low sensitivity.