Boron carbide (chemical formula approximately B4C) is an extremely hard boron–carbon ceramic and covalent material used in tank armor, bulletproof vests, engine sabotage powders, as well as numerous industrial applications. With a Vickers Hardness of >30 GPa, it is one of the hardest known materials, behind cubic boron nitride and diamond.

Titanium diboride (TiB2) is an extremely hard ceramic which has excellent heat conductivity, oxidation stability and resistance to mechanical erosion. TiB2 is also a reasonable electrical conductor, so it can be used as a cathode material in aluminium smelting and can be shaped by electrical discharge machining.

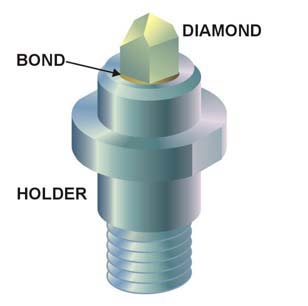

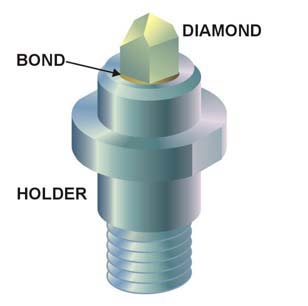

A superhard material is a material with a hardness value exceeding 40 gigapascals (GPa) when measured by the Vickers hardness test. They are highly incompressible solids with high electron density and high bond covalency. As a result of their unique properties, these materials are of great interest in many industrial areas including, but not limited to, abrasives, polishing and cutting tools and wear-resistant and protective coatings.

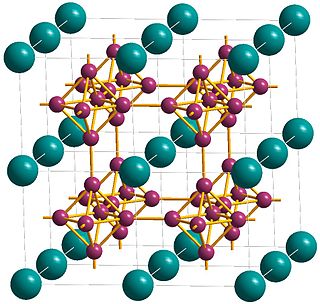

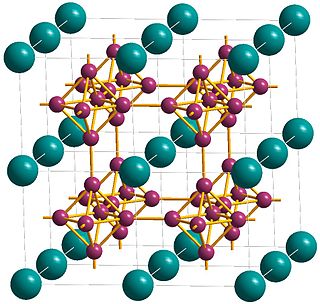

Calcium hexaboride (sometimes calcium boride) is a compound of calcium and boron with the chemical formula CaB6. It is an important material due to its high electrical conductivity, hardness, chemical stability, and melting point. It is a black, lustrous, chemically inert powder with a low density. It has the cubic structure typical for metal hexaborides, with octahedral units of 6 boron atoms combined with calcium atoms. CaB6 and lanthanum-doped CaB6 both show weak ferromagnetic properties, which is a remarkable fact because calcium and boron are neither magnetic, nor have inner 3d or 4f electronic shells, which are usually required for ferromagnetism.

Aluminium diboride (AlB2) is a chemical compound made from the metal aluminium and the metalloid boron. It is one of two compounds of aluminium and boron, the other being AlB12, which are both commonly referred to as aluminium boride.

Aluminium dodecaboride (AlB12) is a superhard chemical compound with 17% aluminium content by weight.

Aluminum magnesium boride or Al3Mg3B56 colliqually known as BAM is a chemical compound of aluminium, magnesium and boron. Whereas its nominal formula is AlMgB14, the chemical composition is closer to Al0.75Mg0.75B14. It is a ceramic alloy that is highly resistive to wear and has an extremely low coefficient of sliding friction, reaching a record value of 0.02 in lubricated AlMgB14−TiB2 composites. First reported in 1970, BAM has an orthorhombic structure with four icosahedral B12 units per unit cell. This ultrahard material has a coefficient of thermal expansion comparable to that of other widely used materials such as steel and concrete.

Yttrium boride refers to a crystalline material composed of different proportions of yttrium and boron, such as YB2, YB4, YB6, YB12, YB25, YB50 and YB66. They are all gray-colored, hard solids having high melting temperatures. The most common form is the yttrium hexaboride YB6. It exhibits superconductivity at relatively high temperature of 8.4 K and, similar to LaB6, is an electron cathode. Another remarkable yttrium boride is YB66. It has a large lattice constant (2.344 nm), high thermal and mechanical stability, and therefore is used as a diffraction grating for low-energy synchrotron radiation (1–2 keV).

Ruthenium borides are compounds of ruthenium and boron. Their most remarkable property is potentially high hardness. Vickers hardness HV = 50 GPa was reported for thin films composed of RuB2 and Ru2B3 phases. This value is significantly higher than those of bulk RuB2 or Ru2B3, but it has to be confirmed independently, as measurements on superhard materials are intrinsically difficult. For example, note that the initial report on extreme hardness of related material rhenium diboride was probably too optimistic.

Tantalum borides are compounds of tantalum and boron most remarkable for their extreme hardness.

Tungsten borides are compounds of tungsten and boron. Their most remarkable property is high hardness. The Vickers hardness of WB or WB2 crystals is ~20 GPa and that of WB4 is ~30 GPa for loads exceeding 3 N.

An inclusion is a solid particle in liquid aluminium alloy. It is usually non-metallic and can be of different nature depending on its source.

Chromium(III) boride, also known as chromium monoboride (CrB), is an inorganic compound with the chemical formula CrB. It is one of the six stable binary borides of chromium, which also include Cr2B,Cr5B3, Cr3B4, CrB2, and CrB4. Like many other transition metal borides, it is extremely hard (21-23 GPa), has high strength (690 MPa bending strength), conducts heat and electricity as well as many metallic alloys, and has a high melting point (~2100 oC). Unlike pure chromium, CrB is known to be a paramagnetic, with a magnetic susceptibility that is only weakly dependent on temperature. Due to these properties, among others, CrB has been considered as a candidate material for wear resistant coatings and high-temperature diffusion barriers.

Iron boride refers to various inorganic compounds with the formula FexBy. Two main iron borides are FeB and Fe2B. Some iron borides possess useful properties such as magnetism, electrical conductivity, corrosion resistance and extreme hardness. Some iron borides have found use as hardening coatings for iron. Iron borides have properties of ceramics such as high hardness, and properties of metal properties, such as thermal conductivity and electrical conductivity. Boride coatings on iron are superior mechanical, frictional, and anti-corrosive. Iron monoboride (FeB) is a grey powder that is insoluble in water. FeB is harder than Fe2B, but is more brittle and more easily fractured upon impact.

5154 aluminium alloy is an alloy in the wrought aluminium-magnesium family. As an aluminium-magnesium alloy, it combines moderate-to-high strength with excellent weldability. 5154 aluminium is commonly used in welded structures such as pressure vessels and ships. As a wrought alloy, it can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility. It is generally not clad.

5754 aluminium alloy is an alloy in the wrought aluminium -magnesium family. It is closely related to the alloys 5154 and 5454. Of the three 5x54 alloys, 5754 is the least alloyed, but only by a small amount. It is used in similar applications. As a wrought alloy, it can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility.

6005A aluminium alloy is an alloy in the wrought aluminium-magnesium-silicon family. It is closely related, but not identical, to 6005 aluminium alloy. Between those two alloys, 6005A is more heavily alloyed, but the difference does not make a marked impact on material properties. It can be formed by extrusion, forging or rolling, but as a wrought alloy it is not used in casting. It cannot be work hardened, but is commonly heat treated to produce tempers with a higher strength at the expense of ductility.

6060 aluminium alloy is an alloy in the wrought aluminium-magnesium-silicon family. It is much more closely related to the alloy 6063 than to 6061. The main difference between 6060 and 6063 is that 6063 has a slightly higher magnesium content. It can be formed by extrusion, forging or rolling, but as a wrought alloy it is not used in casting. It cannot be work hardened, but is commonly heat treated to produce tempers with a higher strength but lower ductility.

6262 aluminium alloy is an alloy in the wrought aluminium-magnesium-silicon family. It is related to 6162 aluminium alloy, but sees much more widespread use. It is notably distinct from 6162, and most other aluminium alloys, in that it contains lead in its alloy composition. It is typically formed by extrusion, forging, or rolling, but as a wrought alloy it is not used in casting. It can also be clad, but that is not common practice with this alloy. It cannot be work hardened, but is commonly heat treated to produce tempers with a higher strength but lower ductility.

The 6463 aluminium alloy is an aluminum alloy in the wrought aluminium-magnesium-silicon family. It is related to 6063 aluminium alloy, but unlike 6063 it is generally not formed using any processes other than extrusion. It cannot be work hardened, but is commonly heat treated to produce tempers with a higher strength but lower ductility. Like 6063, it is often used in architectural applications.