A loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

A textile is a flexible material consisting of a network of natural or artificial fibers. Yarn is produced by spinning raw fibres of wool, flax, cotton, hemp, or other materials to produce long strands. Textiles are formed by weaving, knitting, crocheting, knotting or tatting, felting, or braiding.

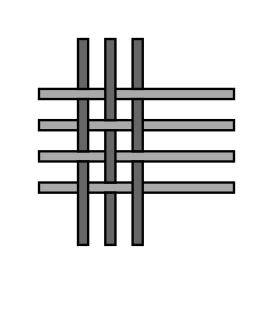

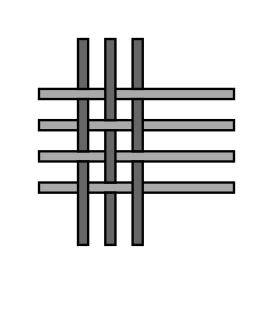

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft or filling. The method in which these threads are inter-woven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band which meets this definition of cloth can also be made using other methods, including tablet weaving, back strap loom, or other techniques without looms.

Drawn thread work is a form of counted-thread embroidery based on removing threads from the warp and/or the weft of a piece of even-weave fabric. The remaining threads are grouped or bundled together into a variety of patterns. The more elaborate styles of drawn thread work use a variety of other stitches and techniques, but the drawn thread parts are their most distinctive element. It is also grouped as whitework embroidery because it was traditionally done in white thread on white fabric and is often combined with other whitework techniques.

Woven fabric is any textile formed by weaving. Woven fabrics are often created on a loom, and made of many threads woven on a warp and a weft. Technically, a woven fabric is any fabric made by interlacing two or more threads at right angles to one another.

Twill is a type of textile weave with a pattern of diagonal parallel ribs. This is done by passing the weft thread over one or more warp threads then under two or more warp threads and so on, with a "step," or offset, between rows to create the characteristic diagonal pattern. Because of this structure, twill generally drapes well.

Warp and weft are the two basic components used in weaving to turn thread or yarn into fabric. The lengthwise or longitudinal warp yarns are held stationary in tension on a frame or loom while the transverse weft is drawn through and inserted over-and-under the warp. A single thread of the weft crossing the warp is called a pick. Terms vary. Each individual warp thread in a fabric is called a warp end or end.

Damask is a reversible figured fabric of silk, wool, linen, cotton, or synthetic fibres, with a pattern formed by weaving. Damasks are woven with one warp yarn and one weft yarn, usually with the pattern in warp-faced satin weave and the ground in weft-faced or sateen weave. Twill damasks include a twill-woven ground or pattern.

Darning is a sewing technique for repairing holes or worn areas in fabric or knitting using needle and thread alone. It is often done by hand, but it is also possible to darn with a sewing machine. Hand darning employs the darning stitch, a simple running stitch in which the thread is "woven" in rows along the grain of the fabric, with the stitcher reversing direction at the end of each row, and then filling in the framework thus created, as if weaving. Darning is a traditional method for repairing fabric damage or holes that do not run along a seam, and where patching is impractical or would create discomfort for the wearer, such as on the heel of a sock.

Even-weave fabric or canvas is any woven textile where the warp and weft threads are of the same size.

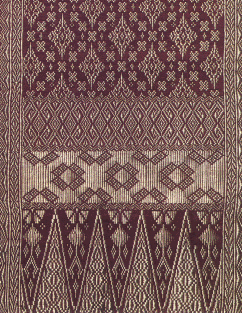

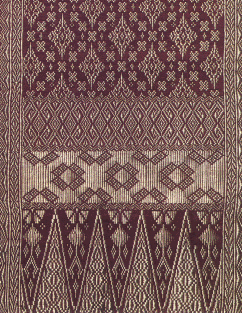

Songket is a fabric that belongs to the brocade family of textiles of the Malay world. It is hand-woven in silk or cotton, and intricately patterned with gold or silver threads. The metallic threads stand out against the background cloth to create a shimmering effect. In the weaving process the metallic threads are inserted in between the silk or cotton weft (latitudinal) threads in a technique called supplementary weft weaving technique.

Plain weave is the most basic of three fundamental types of textile weaves. It is strong and hard-wearing, used for fashion and furnishing fabrics.

A selvage or selvedge is a "self-finished" edge of fabric, keeping it from unraveling and fraying. The term "self-finished" means that the edge does not require additional finishing work, such as hem or bias tape, to prevent fraying.

Silk in the Indian subcontinent is a luxury good. In India, about 97% of the raw mulberry silk is produced in the five Indian states of Karnataka, Andhra Pradesh, Tamil Nadu, West Bengal and Jammu and Kashmir. Mysore and North Bangalore, the upcoming site of a US$20 million "Silk City", contribute to a majority of silk production. Another emerging silk producer is Tamil Nadu where mulberry cultivation is concentrated in Salem, Erode and Dharmapuri districts. Hyderabad, Andhra Pradesh and Gobichettipalayam, Tamil Nadu were the first locations to have automated silk reeling units.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

Ripstop fabrics are woven fabrics, often made of nylon, using a special reinforcing technique that makes them resistant to tearing and ripping. During weaving, (thick) reinforcement threads are interwoven at regular intervals in a crosshatch pattern. The intervals are typically 5 to 8 millimeters. Thin and lightweight ripstop fabrics have a 3-dimensional structure due to the thicker threads being interwoven in thinner cloth. Older lightweight ripstop fabrics display the thicker interlocking thread patterns in the material quite prominently, but more modern weaving techniques make the ripstop threads less obvious. A similar effect can be achieved by weaving two or three fine yarns together at smaller intervals.

A reed is part of a weaving loom, and resembles a comb. It is used to separate and space the warp threads, to guide the shuttle's motion across the loom, and to push the weft threads into place. The reed is securely held by the beater, and consists of a frame with many vertical slits. Floor looms and mechanized looms both use a beater with a reed, whereas Inkle weaving and tablet weaving do not use reeds.

Leno weave is a weave in which two warp yarns are twisted around the weft yarns to provide a strong yet sheer fabric. The standard warp yarn is paired with a skeleton or 'doup' yarn; these twisted warp yarns grip tightly to the weft which causes the durability of the fabric. Leno weave produces an open fabric with almost no yarn slippage or misplacement of threads.