Adobe is a building material made from earth and organic materials. Adobe is Spanish for mudbrick, but in some English-speaking regions of Spanish heritage, the term is used to refer to any kind of earth construction. Most adobe buildings are similar in appearance to cob and rammed earth buildings. Adobe is among the earliest building materials, and is used throughout the world.

A brick is building material used to make walls, pavements and other elements in masonry construction. Traditionally, the term brick referred to a unit composed of clay, but it is now used to denote rectangular units made of clay-bearing soil, sand, and lime, or concrete materials. Bricks can be joined together using mortar, adhesives or by interlocking them. Bricks are produced in numerous classes, types, materials, and sizes which vary with region and time period, and are produced in bulk quantities. Two basic categories of bricks are fired and non-fired bricks.

Pottery is the process of forming vessels and other objects with clay and other ceramic materials, which are fired at high temperatures to give them a hard, durable form. Major types include earthenware, stoneware and porcelain. The place where such wares are made by a potter is also called a pottery. The definition of pottery used by the American Society for Testing and Materials (ASTM), is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products." In archaeology, especially of ancient and prehistoric periods, "pottery" often means vessels only, and figures etc. of the same material are called "terracottas". Clay as a part of the materials used is required by some definitions of pottery, but this is dubious.

Clay is a finely-grained natural rock or soil material that combines one or more clay minerals with possible traces of quartz (SiO2), metal oxides (Al2O3, MgO etc.) and organic matter. Geologic clay deposits are mostly composed of phyllosilicate minerals containing variable amounts of water trapped in the mineral structure. Clays are plastic due to particle size and geometry as well as water content, and become hard, brittle and non–plastic upon drying or firing. Depending on the soil's content in which it is found, clay can appear in various colours from white to dull grey or brown to deep orange-red.

A mudbrick or mud-brick is an air-dried brick, made of a mixture of loam, mud, sand and water mixed with a binding material such as rice husks or straw. Though mudbricks are known from 7000 to 6000 BCE, since 4000 BC, bricks have also been fired, to increase their strength and durability.

Mud is a liquid or semi-liquid mixture of water and any combination of different kinds of soil. It usually forms after rainfall or near water sources. Ancient mud deposits harden over geological time to form sedimentary rock such as shale or mudstone. When geological deposits of mud are formed in estuaries, the resultant layers are termed bay muds.

Mortar is a workable paste used to bind building blocks such as stones, bricks, and concrete masonry units, fill and seal the irregular gaps between them, and sometimes add decorative colors or patterns in masonry walls. In its broadest sense mortar includes pitch, asphalt, and soft mud or clay, such as used between mud bricks. Mortar comes from Latin mortarium meaning crushed.

Plaster is a building material used for the protective or decorative coating of walls and ceilings and for moulding and casting decorative elements. In English "plaster" usually means a material used for the interiors of buildings, while "render" commonly refers to external applications. Another imprecise term used for the material is stucco, which is also often used for plasterwork that is worked in some way to produce relief decoration, rather than flat surfaces.

A tile is a thin object usually square or rectangular in shape. Tile is a manufactured piece of hard-wearing material such as ceramic, stone, metal, baked clay, or even glass, generally used for covering roofs, floors, walls, or other objects such as tabletops. Alternatively, tile can sometimes refer to similar units made from lightweight materials such as perlite, wood, and mineral wool, typically used for wall and ceiling applications. In another sense, a tile is a construction tile or similar object, such as rectangular counters used in playing games. The word is derived from the French word tuile, which is, in turn, from the Latin word tegula, meaning a roof tile composed of fired clay.

Building material is any material which is used for construction purposes. Many naturally occurring substances, such as clay, rocks, sand, and wood, even twigs and leaves, have been used to construct buildings. Apart from naturally occurring materials, many man-made products are in use, some more and some less synthetic. The manufacturing of building materials is an established industry in many countries and the use of these materials is typically segmented into specific specialty trades, such as carpentry, insulation, plumbing, and roofing work. They provide the make-up of habitats and structures including homes.

Earthbag construction is an inexpensive building method using mostly local soil to create structures which are both strong and can be quickly built.

The anagama kiln is an ancient type of pottery kiln brought to Japan from China via Korea in the 5th century. It is a version of the climbing dragon kiln of south China, whose further development was also copied, for example in breaking up the firing space into a series of chambers in the noborigama kiln.

An earth structure is a building or other structure made largely from soil. Since soil is a widely available material, it has been used in construction since prehistoric times. It may be combined with other materials, compressed and/or baked to add strength. Soil is still an economical material for many applications, and may have low environmental impact both during and after construction.

Architectural terracotta refers to a fired mixture of clay and water that can be used in a non-structural, semi-structural, or structural capacity on the exterior or interior of a building. Terracotta is an ancient building material that translates from Latin as "baked earth". It can be unglazed, painted, slip glazed, or glazed. A piece of terracotta is composed of a hollow clay web enclosing a void space or cell. The cell can be installed in compression with mortar or hung with metal anchors. All cells are partially backfilled with mortar.

Superadobe is a form of earthbag construction that was developed by Iranian architect Nader Khalili. The technique uses layered long fabric tubes or bags filled with adobe to form a compression structure. The resulting beehive shaped structures employs corbelled arches, corbelled domes, and vaults to create sturdy single and double-curved shells. It has received growing interest for the past two decades in the natural building and sustainability movements.

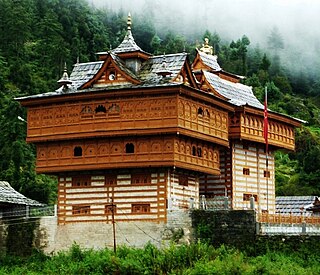

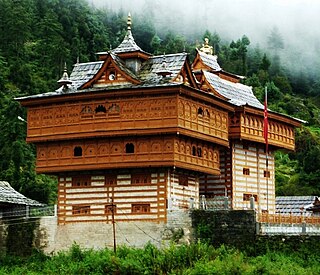

Indian vernacular architecture the informal, functional architecture of structures, often in rural areas of India, built of local materials and designed to meet the needs of the local people. The builders of these structures are unschooled in formal architectural design and their work reflects the rich diversity of India's climate, locally available building materials, and the intricate variations in local social customs and craftsmanship. It has been estimated that worldwide close to 90% of all building is vernacular, meaning that it is for daily use for ordinary, local people and built by local craftsmen.

Bousillage is a mixture of clay and grass or other fibrous substances used as the infill (chinking) between the timbers of a half-timbered building. This material was commonly used by 18th-century French colonial settlers in the historical New France region of the United States and is similar to the material cob and adobe. In French torchis has the same meaning or the meaning of a loaf of this material.

Wattle and daub is a composite building method used for making walls and buildings, in which a woven lattice of wooden strips called wattle is daubed with a sticky material usually made of some combination of wet soil, clay, sand, animal dung and straw. Wattle and daub has been used for at least 6,000 years and is still an important construction method in many parts of the world. Many historic buildings include wattle and daub construction, and the technique is becoming popular again in more developed areas as a low-impact sustainable building technique.

Ceramic building material, often abbreviated to CBM, is an umbrella term used in archaeology to cover all building materials made from baked clay. It is particularly, but not exclusively, used in relation to Roman building materials.