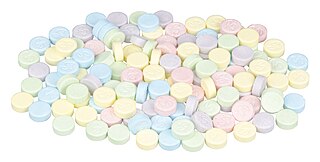

A tablet is a pharmaceutical oral dosage form or solid unit dosage form. Tablets may be defined as the solid unit dosage form of medicament or medicaments with suitable excipients. It comprises a mixture of active substances and excipients, usually in powder form, pressed or compacted from a powder into a solid dose.

A sieve, fine mesh strainer, or sift, is a device for separating wanted elements from unwanted material or for controlling the particle size distribution of a sample, using a screen such as a woven mesh or net or perforated sheet material. The word sift derives from sieve.

In industrial process engineering, mixing is a unit operation that involves manipulation of a heterogeneous physical system with the intent to make it more homogeneous. Familiar examples include pumping of the water in a swimming pool to homogenize the water temperature, and the stirring of pancake batter to eliminate lumps (deagglomeration).

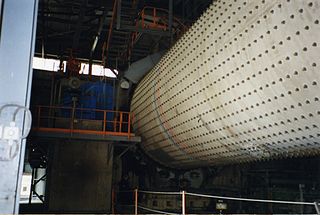

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals, working animal, wind (windmill) or water (watermill). In modern era, they are usually powered by electricity.

A sieve analysis is a practice or procedure used in civil engineering and chemical engineering to assess the particle size distribution of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a fraction of the whole mass.

Mechanical screening, often just called screening, is the practice of taking granulated or crushed ore material and separating it into multiple grades by particle size.

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills. https://en.wikipedia.org/wiki/Concrete_grinder

A high-shear mixer disperses, or transports, one phase or ingredient into a main continuous phase (liquid), with which it would normally be immiscible. A rotor or impeller, together with a stationary component known as a stator, or an array of rotors and stators, is used either in a tank containing the solution to be mixed, or in a pipe through which the solution passes, to create shear. A high-shear mixer can be used to create emulsions, suspensions, lyosols, and granular products. It is used in the adhesives, chemical, cosmetic, food, pharmaceutical, and plastics industries for emulsification, homogenization, particle size reduction, and dispersion.

A tablet press is a mechanical device that compresses powder into tablets of uniform size and weight. A tablet press can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, nutraceuticals, cleaning products, industrial pellets and cosmetics. To form a tablet, the granulated powder material must be metered into a cavity formed by two punches and a die, and then the punches must be pressed together with great force to fuse the material together.

Particle technology is the "science and technology related to the handling and processing of particles and powders." This applies to the production, handling, modification, and use of a wide variety of particulate materials, both wet or dry, in sizes ranging from nanometers to centimeters; its scope spans a range of industries to include chemical, petrochemical, agricultural, food, pharmaceuticals, mineral processing, civil engineering, advanced materials, energy, and the environment.

Pharmaceutical manufacturing is the process of industrial-scale synthesis of pharmaceutical drugs as part of the pharmaceutical industry. The process of drug manufacturing can be broken down into a series of unit operations, such as milling, granulation, coating, tablet pressing, and others.

Granulation is the process of forming grains or granules from a powdery or solid substance, producing a granular material. It is applied in several technological processes in the chemical and pharmaceutical industries. Typically, granulation involves agglomeration of fine particles into larger granules, typically of size range between 0.2 and 4.0 mm depending on their subsequent use. Less commonly, it involves shredding or grinding solid material into finer granules or pellets.

Tableting is a method of pressing medicine or candy into tablets. Confectionery manufacture shares many similarities with pharmaceutical production.

Tumbler screening is a separation method that uses three-dimensional elliptical movement to separate very fine particles from larger ones.

Gyratory equipment, used in mechanical screening and sieving is based on a circular motion of the machine. Unlike other methods, gyratory screen operates in a gentler manner and is more suited to handle fragile things, enabling it to produce finer products. This method is applicable for both wet and dry screening.

High-frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry. They are used to separate feeds containing solid and crushed ores down to less than 200 μm in size, and are applicable to both perfectly wetted and dried feed. The frequency of the screen is mainly controlled by an electromagnetic vibrator which is mounted above and directly connected to the screening surface. Its high-frequency characteristics differentiate it from a normal vibrating screen. High-frequency vibrating screens usually operate at an inclined angle, traditionally varying between 0° and 25° and can go up to a maximum of 45°. They should operate with a low stroke and have a frequency ranging from 1500 to 9000 RPM. Frequency in High frequency screen can be fixed or variable. Variable High Frequency screen is more versatile to tackle varied material condition like particle size distribution, moisture and have higher efficiency due to incremental increase in frequency. G force plays important role in determining specific screening capacity of screen in terms of TPH per sqm. G force increases exponentially with frequency.

Corn wet-milling is a process of breaking corn kernels into their component parts: corn oil, protein, corn starch, and fiber. It uses water and a series of steps to separate the parts to be used for various products.

Agglomerated food powder is a unit operation during which native particles are assembled to form bigger agglomerates, in which the original particle can still be distinguished. Agglomeration can be achieved through processes that use liquid as a binder or methods that do not involve any binder.