A pump is a device that moves fluids, or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy.

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

Hydraulic shock is a pressure surge or wave caused when a fluid in motion is forced to stop or change direction suddenly: a momentum change. It is usually observed in a liquid but gases can also be affected. This phenomenon commonly occurs when a valve closes suddenly at an end of a pipeline system and a pressure wave propagates in the pipe.

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid to flow through it in only one direction.

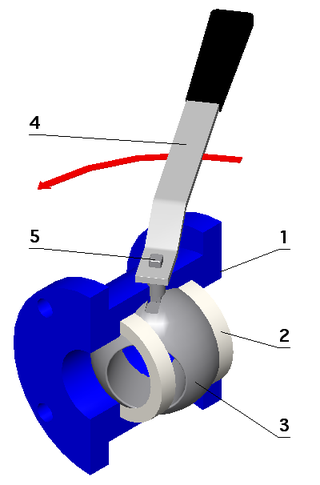

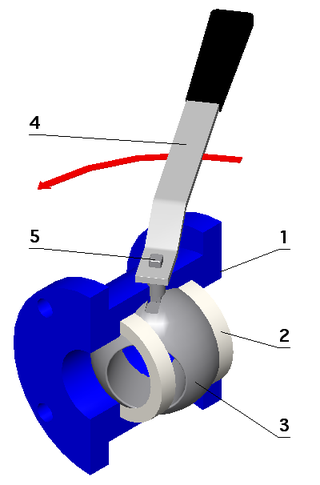

A ball valve is a flow control device which uses a hollow, perforated, and pivoting ball to control fluid flowing through it. It is open when the hole through the middle of the ball is in line with the flow inlet, and closed when it is pivoted 90 degrees by the valve handle, blocking the flow. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve's status. The shut position 1/4 turn could be in either clockwise or counter-clockwise direction.

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes.

Electronic-hydraulic analogies are the representation of electronic circuits by hydraulic circuits. Since electric current is invisible and the processes in play in electronics are often difficult to demonstrate, the various electronic components are represented by hydraulic equivalents. Electricity was originally understood to be a kind of fluid, and the names of certain electric quantities are derived from hydraulic equivalents.

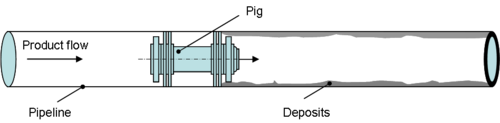

In pipeline transportation, pigging is the practice of using pipeline inspection gauges or gadgets, devices generally referred to as pigs or scrapers, to perform various maintenance operations. This is done without stopping the flow of the product in the pipeline.

A hydraulic brake is an arrangement of braking mechanism which uses brake fluid, typically containing glycol ethers or diethylene glycol, to transfer pressure from the controlling mechanism to the braking mechanism.

Tube cleaning describes the activity of, or device for, the cleaning and maintenance of fouled tubes.

A blowout preventer (BOP) is a specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

In the oil and gas industry, coiled tubing refers to a long metal pipe, normally 1 to 3.25 in in diameter which is supplied spooled on a large reel. It is used for interventions in oil and gas wells and sometimes as production tubing in depleted gas wells. Coiled tubing is often used to carry out operations similar to wirelining. The main benefits over wireline are the ability to pump chemicals through the coil and the ability to push it into the hole rather than relying on gravity. Pumping can be fairly self-contained, almost a closed system, since the tube is continuous instead of jointed pipe. For offshore operations, the 'footprint' for a coiled tubing operation is generally larger than a wireline spread, which can limit the number of installations where coiled tubing can be performed and make the operation more costly. A coiled tubing operation is normally performed through the drilling derrick on the oil platform, which is used to support the surface equipment, although on platforms with no drilling facilities a self-supporting tower can be used instead. For coiled tubing operations on sub-sea wells a mobile offshore drilling unit (MODU) e.g. semi-submersible, drillship etc. has to be utilized to support all the surface equipment and personnel, whereas wireline can be carried out from a smaller and cheaper intervention vessel. Onshore, they can be run using smaller service rigs, and for light operations a mobile self-contained coiled tubing rig can be used.

A surge tank is a standpipe or storage reservoir at the downstream end of a closed aqueduct, feeder pipe, or dam to absorb sudden rises of pressure, as well as to quickly provide extra water during a brief drop in pressure.

Black powder is an industry name for the abrasive, reactive particulate contamination present in all gas and hydrocarbon fluid transmission lines. Black powder ranges from light brown to black, and the mineral makeup varies per production field around the world.

High-density solids pumps are hydrostatically operating machines which displace the medium being pumped and thus create a flow.

Ice pigging is a process in which an ice slurry is pumped through a pipe, forcefully removing unwanted deposits and leaving the pipe clean. It has many applications in the water, sewage, and food industries. Ice pigging was invented and first patented by Professor Joe Quarini of the University of Bristol.

Hydraulics is a topic in engineering dealing with the mechanical properties of liquids.

The peeler centrifuge is a device that performs by rotating filtration basket in an axis. A centrifuge follows on the principle of centrifugal force to separate solids from liquids by density difference. High rotation speed provides high centrifugal force that allows the suspended solid in feed to settle on the inner surface of basket. There are three kinds of centrifuge, horizontal, vertical peeler centrifuge and siphon peeler centrifuge. These classes of instrument apply to various areas such as fertilisers, pharmaceutical, plastics and food including artificial sweetener and modified starch.

Wax deposition or paraffin deposition refers to the accumulation of paraffin wax on the surface of a substance, typically a liquid or gas. This can occur in a variety of contexts, including the production and transport of oil and natural gas, the refining of petroleum products, and the storage and transport of chemicals. For the transportation of crude oil in a pipeline, wax can deposit on to the inner surface of the pipeline, reducing the area for fluid to flow and increasing the pressure requirement for fluid to flow. To prevent wax deposition, various techniques can be used, including heating the fluid to dissolve wax back into the oil phase, adding chemicals to prevent wax formation, and using specialized equipment or a pig to remove the wax deposit from the pipe wall surface.