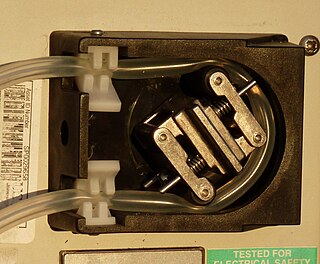

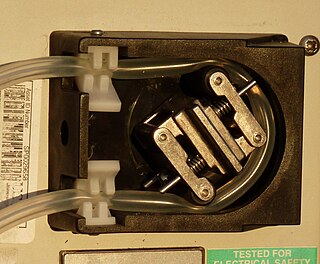

A peristaltic pump is a type of positive displacement pump used for pumping a variety of fluids, they are also commonly known as roller pumps. The fluid is contained within a flexible tube fitted inside a circular pump casing. A rotor with a number of "rollers", "shoes", "wipers", or "lobes" attached to the external circumference of the rotor compresses the flexible tube. As the rotor turns, the part of the tube under compression is pinched closed thus forcing the fluid to be pumped to move through the tube. Additionally, as the tube opens to its natural state after the passing of the cam fluid flow is induced to the pump. This process is called peristalsis and is used in many biological systems such as the gastrointestinal tract. Typically, there will be two or more rollers, or wipers, occluding the tube, trapping between them a body of fluid. The body of fluid is then transported, at ambient pressure, toward the pump outlet. Peristaltic pumps may run continuously, or they may be indexed through partial revolutions to deliver smaller amounts of fluid.

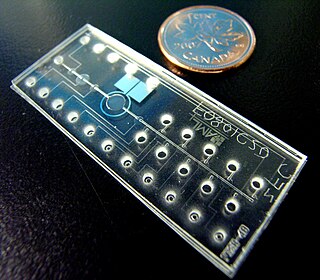

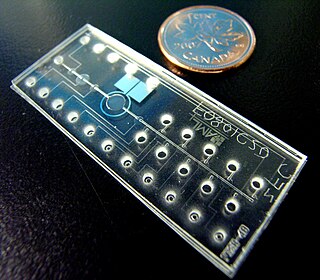

Digital microfluidics (DMF) is another platform for lab-on-a-chip systems that is based upon the manipulation of microdroplets. Droplets are dispensed, moved, stored, mixed, reacted, or analyzed on a platform with a set of insulated electrodes. Digital microfluidics can be used together with analytical analysis procedures such as mass spectrometry, colorimetry, electrochemical, and electrochemiluminescense.

Electroosmotic flow is the motion of liquid induced by an applied potential across a porous material, capillary tube, membrane, microchannel, or any other fluid conduit. Because electroosmotic velocities are independent of conduit size, as long as the electrical double layer is much smaller than the characteristic length scale of the channel, electroosmotic flow will have little effect. Electroosmotic flow is most significant when in small channels. Electroosmotic flow is an essential component in chemical separation techniques, notably capillary electrophoresis. Electroosmotic flow can occur in natural unfiltered water, as well as buffered solutions.

A surface acoustic wave (SAW) is an acoustic wave traveling along the surface of a material exhibiting elasticity, with an amplitude that typically decays exponentially with depth into the material.

Electrohydrodynamics (EHD), also known as electro-fluid-dynamics (EFD) or electrokinetics, is the study of the dynamics of electrically charged fluids. It is the study of the motions of ionized particles or molecules and their interactions with electric fields and the surrounding fluid. The term may be considered to be synonymous with the rather elaborate electrostrictive hydrodynamics. ESHD covers the following types of particle and fluid transport mechanisms: electrophoresis, electrokinesis, dielectrophoresis, electro-osmosis, and electrorotation. In general, the phenomena relate to the direct conversion of electrical energy into kinetic energy, and vice versa.

A hydraulic circuit is a system comprising an interconnected set of discrete components that transport liquid. The purpose of this system may be to control where fluid flows or to control fluid pressure. For example, hydraulic machinery uses hydraulic circuits to move heavy loads. The approach of describing a fluid system in terms of discrete components is inspired by the success of electrical circuit theory. Just as electric circuit theory works when elements are discrete and linear, hydraulic circuit theory works best when the elements are discrete and linear. This usually means that hydraulic circuit analysis works best for long, thin tubes with discrete pumps, as found in chemical process flow systems or microscale devices.

Nanofluidics is the study of the behavior, manipulation, and control of fluids that are confined to structures of nanometer characteristic dimensions. Fluids confined in these structures exhibit physical behaviors not observed in larger structures, such as those of micrometer dimensions and above, because the characteristic physical scaling lengths of the fluid, very closely coincide with the dimensions of the nanostructure itself.

Lateral flow tests, also known as lateral flow immunochromatographic assays, are simple cellulose-based devices intended to detect the presence of a target analyte in liquid sample (matrix) without the need for specialized and costly equipment, though many lab-based applications exist that are supported by reading equipment. Typically, these tests are used for medical diagnostics either for home testing, point of care testing, or laboratory use. A widely spread and well known application is the home pregnancy test.

An electroosmotic pump (EOP), or EO pump, is used for generating flow or pressure by use of an electric field. One application of this is removing liquid flooding water from channels and gas diffusion layers and direct hydration of the proton exchange membrane in the membrane electrode assembly (MEA) of the proton exchange membrane fuel cells.

Bio-MEMS is an abbreviation for biomedical microelectromechanical systems. Bio-MEMS have considerable overlap, and is sometimes considered synonymous, with lab-on-a-chip (LOC) and micro total analysis systems (μTAS). Bio-MEMS is typically more focused on mechanical parts and microfabrication technologies made suitable for biological applications. On the other hand, lab-on-a-chip is concerned with miniaturization and integration of laboratory processes and experiments into single chips. In this definition, lab-on-a-chip devices do not strictly have biological applications, although most do or are amenable to be adapted for biological purposes. Similarly, micro total analysis systems may not have biological applications in mind, and are usually dedicated to chemical analysis. A broad definition for bio-MEMS can be used to refer to the science and technology of operating at the microscale for biological and biomedical applications, which may or may not include any electronic or mechanical functions. The interdisciplinary nature of bio-MEMS combines material sciences, clinical sciences, medicine, surgery, electrical engineering, mechanical engineering, optical engineering, chemical engineering, and biomedical engineering. Some of its major applications include genomics, proteomics, molecular diagnostics, point-of-care diagnostics, tissue engineering, single cell analysis and implantable microdevices.

Cell sorting methods are used to separate cells isolated from an organism's tissues according to their type. Cells are mostly commonly separated relying on differences in cell size, shape (morphology), and surface protein expression. The resulting homogenous populations of cells have important applications in research and as therapeutics.

The centrifugal micro-fluidic biochip or centrifugal micro-fluidic biodisk is a type of lab-on-a-chip technology, also known as lab-on-a-disc, that can be used to integrate processes such as separating, mixing, reaction and detecting molecules of nano-size in a single piece of platform, including a compact disk or DVD. This type of micro-fluidic biochip is based upon the principle of microfluidics; to take advantage of noninertial pumping for lab-on-a-chip devices using noninertial valves and switches under centrifugal force and Coriolis effect to distribute fluids about the disks in a highly parallel order.

An organ-on-a-chip (OOC) is a multi-channel 3-D microfluidic cell culture chip that simulates the activities, mechanics and physiological response of entire organs and organ systems, a type of artificial organ. It constitutes the subject matter of significant biomedical engineering research, more precisely in bio-MEMS. The convergence of labs-on-chips (LOCs) and cell biology has permitted the study of human physiology in an organ-specific context, introducing a novel model of in vitro multicellular human organisms. One day, they will perhaps abolish the need for animals in drug development and toxin testing.

Microfluidic cell culture integrates knowledge from biology, biochemistry, engineering, and physics to develop devices and techniques for culturing, maintaining, analyzing, and experimenting with cells at the microscale. It merges microfluidics, a set of technologies used for the manipulation of small fluid volumes within artificially fabricated microsystems, and cell culture, which involves the maintenance and growth of cells in a controlled laboratory environment. Microfluidics has been used for cell biology studies as the dimensions of the microfluidic channels are well suited for the physical scale of cells. For example, eukaryotic cells have linear dimensions between 10-100 μm which falls within the range of microfluidic dimensions. A key component of microfluidic cell culture is being able to mimic the cell microenvironment which includes soluble factors that regulate cell structure, function, behavior, and growth. Another important component for the devices is the ability to produce stable gradients that are present in vivo as these gradients play a significant role in understanding chemotactic, durotactic, and haptotactic effects on cells.

A microvalve is microscale valve, i.e. a microfluidic two-port component that regulates the flow between two fluidic ports. Microvalves are basic components in microfluidic devices, such as Labs-on-a-chip, where they are used to control the fluidic transport. During the period 1995-2005, a lot of Microelectromechanical systems-based microvalves were developed.

Microfluidics refers to the flow of fluid in channels or networks with at least one dimension on the micron scale. In open microfluidics, also referred to as open surface microfluidics or open-space microfluidics, at least one boundary confining the fluid flow of a system is removed, exposing the fluid to air or another interface such as a second fluid.