Related Research Articles

A boiling water reactor (BWR) is a type of nuclear reactor used for the generation of electrical power. It is the second most common type of electricity-generating nuclear reactor after the pressurized water reactor (PWR).

A nuclear meltdown is a severe nuclear reactor accident that results in core damage from overheating. The term nuclear meltdown is not officially defined by the International Atomic Energy Agency or by the United States Nuclear Regulatory Commission. It has been defined to mean the accidental melting of the core of a nuclear reactor, however, and is in common usage a reference to the core's either complete or partial collapse.

The RBMK is a class of graphite-moderated nuclear power reactor designed and built by the Soviet Union. It is somewhat like a boiling water reactor as water boils in the pressure tubes. It is one of two power reactor types to enter serial production in the Soviet Union during the 1970s, the other being the VVER reactor. The name refers to its design where instead of a large steel pressure vessel surrounding the entire core, the core is surrounded by a cylindrical annular steel tank inside a concrete vault and each fuel assembly is enclosed in an individual 8 cm (inner) diameter pipe. The channels also contain the coolant, and are surrounded by graphite.

A breeder reactor is a nuclear reactor that generates more fissile material than it consumes. These reactors can be fueled with more-commonly available isotopes of uranium and thorium, such as uranium-238 and thorium-232, as opposed to the rare uranium-235 which is used in conventional reactors. These materials are called fertile materials since they can be bred into fuel by these breeder reactors.

A fast-neutron reactor (FNR) or fast-spectrum reactor or simply a fast reactor is a category of nuclear reactor in which the fission chain reaction is sustained by fast neutrons, as opposed to slow thermal neutrons used in thermal-neutron reactors. Such a fast reactor needs no neutron moderator, but requires fuel that is relatively rich in fissile material when compared to that required for a thermal-neutron reactor. Around 20 land based fast reactors have been built, accumulating over 400 reactor years of operation globally. The largest was the Superphénix sodium cooled fast reactor in France that was designed to deliver 1,242 MWe. Fast reactors have been studied since the 1950s, as they provide certain advantages over the existing fleet of water-cooled and water-moderated reactors. These are:

Passive nuclear safety is a design approach for safety features, implemented in a nuclear reactor, that does not require any active intervention on the part of the operator or electrical/electronic feedback in order to bring the reactor to a safe shutdown state, in the event of a particular type of emergency. Such design features tend to rely on the engineering of components such that their predicted behaviour would slow down, rather than accelerate the deterioration of the reactor state; they typically take advantage of natural forces or phenomena such as gravity, buoyancy, pressure differences, conduction or natural heat convection to accomplish safety functions without requiring an active power source. Many older common reactor designs use passive safety systems to a limited extent, rather, relying on active safety systems such as diesel-powered motors. Some newer reactor designs feature more passive systems; the motivation being that they are highly reliable and reduce the cost associated with the installation and maintenance of systems that would otherwise require multiple trains of equipment and redundant safety class power supplies in order to achieve the same level of reliability. However, weak driving forces that power many passive safety features can pose significant challenges to effectiveness of a passive system, particularly in the short term following an accident.

The integral fast reactor (IFR), originally the advancedliquid-metal reactor (ALMR), is a design for a nuclear reactor using fast neutrons and no neutron moderator. IFRs can breed more fuel and are distinguished by a nuclear fuel cycle that uses reprocessing via electrorefining at the reactor site.

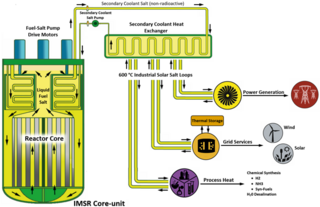

A molten-salt reactor (MSR) is a class of nuclear fission reactor in which the primary nuclear reactor coolant and/or the fuel is a mixture of molten salt with a fissile material.

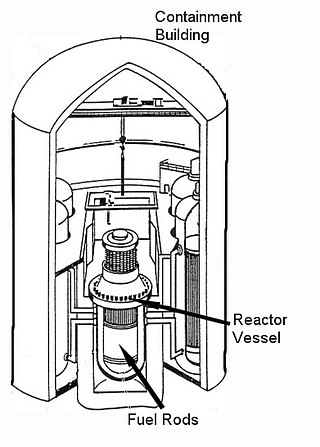

A containment building is a reinforced steel, concrete or lead structure enclosing a nuclear reactor. It is designed, in any emergency, to contain the escape of radioactive steam or gas to a maximum pressure in the range of 275 to 550 kPa. The containment is the fourth and final barrier to radioactive release, the first being the fuel ceramic itself, the second being the metal fuel cladding tubes, the third being the reactor vessel and coolant system.

The Advanced CANDU reactor (ACR), or ACR-1000, was a proposed Generation III+ nuclear reactor design, developed by Atomic Energy of Canada Limited (AECL). It combined features of the existing CANDU pressurised heavy water reactors (PHWR) with features of light-water cooled pressurized water reactors (PWR). From CANDU, it took the heavy water moderator, which gave the design an improved neutron economy that allowed it to burn a variety of fuels. It replaced the heavy water cooling loop with one containing conventional light water, reducing costs. The name refers to its design power in the 1,000 MWe class, with the baseline around 1,200 MWe.

Generation IVreactors are nuclear reactor design technologies that are envisioned as successors of generation III reactors. The Generation IV International Forum (GIF) – an international organization that coordinates the development of generation IV reactors – specifically selected six reactor technologies as candidates for generation IV reactors. The designs target improved safety, sustainability, efficiency, and cost. The World Nuclear Association in 2015 suggested that some might enter commercial operation before 2030.

The lead-cooled fast reactor is a nuclear reactor design that uses molten lead or lead-bismuth eutectic coolant. These materials can be used as the primary coolant because they have low neutron absorption and relatively low melting points. Neutrons are slowed less by interaction with these heavy nuclei so these reactors operate with fast neutrons.

The water-water energetic reactor (WWER), or VVER is a series of pressurized water reactor designs originally developed in the Soviet Union, and now Russia, by OKB Gidropress. The idea of such a reactor was proposed at the Kurchatov Institute by Savely Moiseevich Feinberg. VVER were originally developed before the 1970s, and have been continually updated. They were one of the initial reactors developed by the USSR, the other being the infamous RBMK. As a result, the name VVER is associated with a wide variety of reactor designs spanning from generation I reactors to modern generation III+ reactor designs. Power output ranges from 70 to 1300 MWe, with designs of up to 1700 MWe in development. The first prototype VVER-210 was built at the Novovoronezh Nuclear Power Plant.

The Economic Simplified Boiling Water Reactor (ESBWR) is a passively safe generation III+ reactor design derived from its predecessor, the Simplified Boiling Water Reactor (SBWR) and from the Advanced Boiling Water Reactor (ABWR). All are designs by GE Hitachi Nuclear Energy (GEH), and are based on previous Boiling Water Reactor designs.

The advanced heavy-water reactor (AHWR) or AHWR-300 is the latest Indian design for a next-generation nuclear reactor that burns thorium in its fuel core. It is slated to form the third stage in India's three-stage fuel-cycle plan. This phase of the fuel cycle plan was supposed to be built starting with a 300 MWe prototype in 2016.

The three primary objectives of nuclear reactor safety systems as defined by the U.S. Nuclear Regulatory Commission are to shut down the reactor, maintain it in a shutdown condition and prevent the release of radioactive material.

The B&W mPower was a proposed small modular reactor designed by Babcock & Wilcox, and to be built by Generation mPower LLC, a joint venture of Babcock & Wilcox and Bechtel. It was a Generation III+ integral pressurized water reactor concept.

Boiling water reactor safety systems are nuclear safety systems constructed within boiling water reactors in order to prevent or mitigate environmental and health hazards in the event of accident or natural disaster.

The VVER-TOI or WWER-TOI is a generation III+ nuclear power reactor based on VVER technology developed by Rosatom. The VVER-TOI design is intended to improve the competitiveness of Russian VVER technology in international markets. It would use VVER-1300/510 water pressurized reactors constructed to meet modern nuclear and radiation safety requirements.

The integral molten salt reactor (IMSR) is a nuclear power plant design targeted at developing a commercial product for the small modular reactor (SMR) market. It employs molten salt reactor technology which is being developed by the Canadian company Terrestrial Energy.

References

- Matzie, R.A.; Longo, J.; Bradbury, R.B.; Teare, K.R.; Hayns, M.R. (August 1992). "Design of the Safe Integral Reactor". Nuclear Engineering and Design. 136 (1–2): 73–83. doi:10.1016/0029-5493(92)90114-B.