Type 72 Non-Metallic is a Chinese circular, plastic bodied landmine which is designed to damage or destroy a vehicle by blast effect.

The L9 Bar Mine is a large rectangular British anti-tank landmine. The bar mine's principal advantage is its long length, and therefore its trigger length. A typical anti-tank landmine is circular, and a vehicle's wheels or tracks, which make up only a small proportion of its total width, must actually press on the mine to activate it. To increase the probability of a vehicle striking the mine, the mine's effective trigger width must be increased.

The PMN series of blast anti-personnel mines were designed and manufactured in the Soviet Union. They are one of the most widely used and commonly found devices during demining operations.

The VS-50 is a circular plastic cased anti-personnel blast mine, formerly manufactured by the now-defunct Valsella Meccanotecnica SpA, an Italian high-tech defence industry specialized in area denial systems which was also the manufacturer of the Valmara 69 and one of the first industries in the world to implement plastic construction for landmines. The design is similar to the TS-50 and VS-MK2 mine. It is blast resistant and can be used in a minimum metal configuration. Though unlikely to kill, the explosive charge contained within a VS-50 is quite sufficient to destroy the victim's foot: the blast is capable of penetrating 5 mm of mild steel leaving an 80 mm-diameter hole.

The SACI is an Italian Bakelite cased minimum metal anti-tank blast landmine. A number of variants were produced with varying amounts of explosive. The mine has three fuze wells on the top surface, that are covered with a pressure plate. Several types of fuzes were made including a low metal fuze. Combined with the low metal fuze the mine is very difficult to detect with mine detectors.

The Mk 7 mine was a circular British anti-tank blast mine. It replaced the World War 2-era Mk 5 mine, and has in turn been replaced by the L9 Bar Mine.

A minimum metal mine is a land mine that is designed to use the smallest amount of metal possible in its construction. Typically, the only metal components are located inside the fuze mechanism which triggers detonation. Both minimum metal anti-tank and anti-personnel mines exist. Some designs contain virtually no metal at all e.g. less than a gram. This is achieved by encasing the explosive charge in a plastic, wooden, or glass body, with metallic components limited to the few small parts in the fuze which can not easily be made from other materials, such as the spring, striker tip, and shear pin. Minimum metal mines are extremely difficult to detect using conventional metal mine detectors and usually require modern techniques, such as robotic Multi Period Sensing (MPS) equipment, to identify, but it is still too difficult to find non-metallic mines. These techniques are usually restricted to well-funded international mine clearing organizations and major militaries, making minimum metal mines especially pernicious where they are encountered.

A Blast resistant mine is a landmine with a fuze which is designed to be insensitive to the shock wave from a nearby explosion. This feature makes it difficult or impossible to clear such mines using explosive minefield breaching techniques. As a result, the process of clearing minefields is slower and more complex. Blast resistance can be achieved in a number of ways.

The MC-71 is a Romanian tilt-rod fuzed anti-tank landmine. The mine's body consists of two truncated cones, the lower of the cones contains the main charge and fuzing mechanism. The main charge is a large shaped charge, which triggers 200 ms to 400 ms after the tilt rod is activated. The tilt rod can be deployed away from the mine, potentially making it effective against clearance vehicles using mine rollers and mine flails.

An anti-handling device is an attachment to or integral part of a landmine or other munition e.g. some fuze types found in general purpose air-dropped bombs, cluster bombs and sea mines. It is designed to prevent tampering. When the protected device is disturbed, it detonates, killing or injuring anyone within the blast area. There is a strong functional overlap of booby traps and anti-handling devices.

The TM-44 was a circular metal-cased Soviet anti-tank landmine used during the Second World War. The mine's case consisted of a short cylinder with the entire top surface being used as a pressure plate. The mine was normally painted olive drab and was broadly similar to the earlier, smaller, TM-41 mine.

The VAR/40, VAR/100 and VAR/100/SP are Italian anti-personnel blast landmines produced by the Tecnovar italiana S.p.A. company.

The Bakelite anti-tank mine type I and type II were Italian anti-tank mines produced during the Second World War. As the name suggests, the mines used Bakelite cases and used relatively few metal components, making them difficult to detect with mine detectors of the era. It was primarily used to deter pursuit when withdrawing from an area.

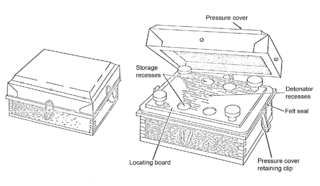

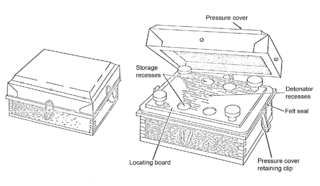

The CC 48 is an Italian wooden cased minimum metal anti-tank mine that was used during the Second World War. The mine uses a shaped TNT explosive charge to produce a directional cutting effect. The mine uses two PMC/43 fuzes, but these can be replaced with PMC/42/2 anti-personnel fuzes, combined with weakening the lid this can make it sensitive enough to be detonated by the weight of a mine.

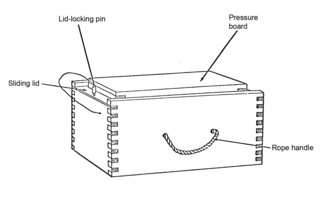

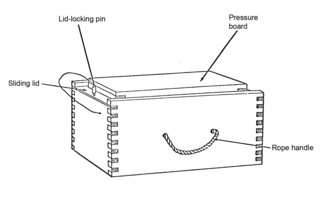

The CS 42/2 is an Italian wooden cased anti-tank mine used during the Second World War. The mine uses four PMC 43 buttons, which can be substituted for Model 42/2 fuzes to make it function as an Anti-personnel mine.

The CS 42/3 is an Italian wooden cased anti-tank mine used during the Second World War. Like the earlier CS 42/2 mine it uses four PMC 43 fuzes. It is a minimum metal mine, containing no metal.

The M1935 is a French heavy anti-tank mine. It consists of a large heavy steel base plate with a hinged thin steel lid. Inside the lid it has a rectangular steel container, which holds the explosive charge. The mines are laid at a minimum interval of six feet.

The Pignone P-1 and Pignone P-2 were plastic cased Italian anti-tank blast mines produced and used during the Second World War in North Africa and Italy. Although the mines had plastic cases, they had a number of metal components, rendering them detectable to mine detectors.

The Type 9 wooden anti-tank mine was an Italian bar type anti-tank mine used during World War II in North Africa. The box consisted of a lower section, containing the large warhead and fuzes and an upper, overlapping lid with two pivoting wooden covers that sat over the two fuzes. The fuzes were designed as a pivoting lever, and downward motion of the lid caused the lever to pull back a striker, compressing a striker spring until the pivoting action moved the lever enough to release the striker. The striker then impacted a blank cartridge, firing it, triggering a detonator charge, followed by the main charge.