Related Research Articles

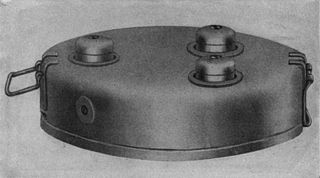

The Tellermine 42 (T.Mi.42) was a German metal-cased anti-tank blast mine used during the Second World War. The mine was a development of the Tellermine 35 with improved resistance to blast. It was followed by the simplified Tellermine 43.

The Tellermine 43 was a German circular steel cased anti-tank blast mine used during the Second World War. It was a simplified version of the Tellermine 42, which enabled simpler production techniques. Between March 1943 and the end of World War II, over 3.6 million Tellermine 43s were produced by Germany. Copies of the mine were produced by several countries including Denmark (M/47), France and Yugoslavia (TMM-1).

The TM-57 mine is a large, circular Soviet metal-cased blast anti-tank mine. It can either be triggered by a pressure or a tilt-rod fuze. A development of the TM-46 mine, it is found in Africa, the Middle East, and South East Asia.

The M15 mine is a large circular United States anti-tank blast mine, first deployed during the Korean War. Essentially, it is a larger version of the M6A2 anti-tank mine, which it replaced. Although the M15 has been superseded by the M19 mine, the U.S. retains large stocks of M15s because they are still regarded as reliable and effective weapons. When used against main battle tanks the M15 is primarily a "track-breaker" which creates mobility kills, but has a comparatively small likelihood of causing crew fatalities. However, when used against lighter vehicles such as APCs or unarmored vehicles such as trucks the damage inflicted is much more severe.

The VS-50 is a circular plastic cased anti-personnel blast mine, formerly manufactured by the now-defunct Valsella Meccanotecnica SpA, an Italian high-tech defence industry specialized in area denial systems which was also the manufacturer of the Valmara 69 and one of the first industries in the world to implement plastic construction for landmines. The design is similar to the TS-50 and VS-MK2 mine. It is blast resistant and can be used in a minimum metal configuration. Though unlikely to kill, the explosive charge contained within a VS-50 is quite sufficient to destroy the victim's foot: the blast is capable of penetrating 5 mm of mild steel leaving an 80 mm-diameter hole.

The M7 is a small, metal-cased United States anti-tank blast mine that was used during the Second World War. It was based on the British Hawkins grenade. Approximately 2.5 million were produced before production ceased, and although it has long since been withdrawn from U.S. service, it can be found in Angola, Burma, Cambodia, Chad, Eritrea, Ethiopia, Korea, Lebanon, Myanmar, Somalia, Thailand, and Zambia.

The M19 is a large square plastic cased United States anti-tank blast mine. Intended to replace the M15 mine, the design dates from the mid-1960s and contains only two metal components: the copper detonator capsule and a stainless steel firing pin which weighs 2.86 grams. It is a minimum metal mine, which makes it very difficult to detect after it has been emplaced. This mine is produced under licence in Chile, South Korea and Turkey. A copy is produced in Iran. It is found in Afghanistan, Angola, Chad, Chile, Cyprus, Iran, Iraq, Jordan, South Korea, Lebanon, the Western Sahara, and Zambia.

The SACI is an Italian Bakelite cased minimum metal anti-tank blast landmine. A number of variants were produced with varying amounts of explosive. The mine has three fuze wells on the top surface, that are covered with a pressure plate. Several types of fuzes were made including a low metal fuze. Combined with the low metal fuze the mine is very difficult to detect with mine detectors.

The Tellermine 29 is a round, metal-cased German anti-tank blast landmine. It first entered service in 1929, and the initial German defence plan was to purchase 6,000 a year, but in January 1931 it was decided to speed up the purchase process, and 61,418 were ordered. By 1937, with the introduction of the Tellermine 35, it was being used for training, and the majority were sent to warehouses.

The M1, M1A1 and M4 are circular steel cased United States anti-tank blast mines with a distinctive cross shaped pressure spider. The mine was used during the Second World War and a copy produced in Argentina was used during the Falklands War. Another copy is produced in China. designated the No. 4 mine. Variants of the mine have also been deployed in Chad and Tunisia.

The P2 Mk2 and P3 Mk2 are Pakistani plastic cased minimum metal anti-tank blast mines. The P2 Mk2 has a square case with a central circular ribbed pressure plate, the P3 is circular with a central circular pressure plate. Both mines use anti-personnel mines as the fuse, typically the either the P4 Mk1 or P2 Mk2 anti-personnel mines. The anti-personnel mine sits in a cavity below the pressure plate, when enough pressure is place on the pressure plate of the mine, it collapses onto the anti-personnel mine triggering it and the main charge which sits below it. A yellow canvas carrying strap is normally fitted to the side of the mine. The mines have a secondary fuse well on the bottom which can be used with anti-handling devices. A GLM-2 electronic booby trap can be fitted to the cavity under the pressure plate. The mine is supplied with a steel disc which makes the mine more easily detectable, although this is seldom used. Since 1997 only a detectable version of the mine has been produced, and to comply with the Convention on Conventional Weapons amended protocol II, Pakistani stocks of the mine are being retrofitted with steel detection discs. The mines are found in Afghanistan, Angola, Eritrea, Ethiopia, Pakistan, Somalia, and Tajikistan.

The No 8 mine is a South African circular plastic cased minimum metal anti-tank blast mine. The mine has a large pressure plate on top of which is an oversize arming lever whose position at either of two sets of lugs either indicates "ARMED" or "SAFE". The mine can be fitted with a number of electronic anti-handling devices as well as seismic and magnetic influence devices. The mine is found in Angola, Namibia, Zambia, and Zimbabwe.

The TMM-1 is a circular, metal-cased, Yugoslavian anti-tank blast mine. It is a direct copy of the German Tellermine 43. The mine has a central fuze well that is covered by a screw on pressure plate. Two secondary fuze well are fitted to the side and bottom of the mine allowing the installation of anti-handling devices. The mine is found in Bosnia, Croatia, and Serbia.

The TM 65 is a circular Finnish minimum metal anti-tank blast mine. It is broadly based on the Russian TM-62 mine. The mines body is made from a thin shell of fibreglass over a cast block of explosive, with a central fuze well that holds the pressure fuze. The original TM 65 used a US-65 fuze as used in the SM-65 anti-personnel mine, the later TM 65 77 uses a pressure fuze similar to the Russian MV-5 fuze called Painesytytin 77.

ADWAT is a French anti-tank blast mine used with the Matenin mine laying system. The mine has the same casing as the MI AC PR series of mines. The mine has a mechanical and electronic fuze. The mine incorporates a 30-minute arming delay, after which either the electronic or mechanical fuze can trigger the mine. The electronic fuze can be programmed using an external programmer with a three-pin connection to self-neutralize, self-destruct and act as an anti-handling device, with an active period of between one and 365 days.

The NR 26 is a Dutch circular minimum metal anti-tank blast mine similar to the French M51 MACI. The mine uses an NR 26 friction pressure fuze with a sheer collar designed to give way at a load of 350 kg. Two secondary fuze wells for anti-handling devices are fitted to the side and base of the mine, and carrying handle is fitted to the side of the mine.

The MAT/5 is an Italian circular, plastic-cased minimum metal blast resistant anti-tank blast mine. It uses a pneumatic fuze which is resistant to shock and blast, and is also claimed to be resistant to mine flails and mine rollers. The mine's plastic case is waterproof, and it can be laid in shallow water. Additionally the mine will function upside down. The mine can be fitted with anti-handling devices. The mine is no longer in production.

The MAT/6 is an Italian circular synthetic resin-cased minimum metal blast resistant anti-tank blast mine. It uses a pneumatic fuze which is resistant to shock and blast, and is also claimed to be resistant to mine flails and mine rollers. The mine's plastic case is waterproof, and it can be laid in shallow water. Anti-handling devices may be fitted to the mine.

The MATS/2 is a scatterable Italian circular, plastic-cased minimum metal blast resistant anti-tank blast mine. It uses a pneumatic fuse which is resistant to shock and blast similar to the fuse fitted to the TS-50. The mine's plastic case is waterproof, and the mine can be scattered from a helicopter traveling at up to 200 km/h using the Tecnovar DAT dispensing system. A secondary fuse well is provided in the base for the fitting of anti-handling devices.

The MI AC Disp F1 Minotaur mine is a French scatterable anti-tank mine. The mines can also be scattered from 155 millimetre artillery shells, which can hold six of the mines. The mine is cylindrical with two Misznay Schardin effect warheads, one on each side of the mine, with a 600 gram charge. The warhead is claimed to be able to penetrate 90 mm of armour at a distance of 0.5 m. It uses a magnetic influence fuze combined with an anti-handling device which arms itself 64 seconds after launch. At the end of its active life, which is set to between one and 96 hours the mine self-destructs. The land based scattering system can launch mines to a range of up to 300 m.

References

- Jane's Mines and Mine Clearance 2005-2006

- MI AC PR mine at ORDATA