In horology, a maintaining power is a mechanism for keeping a clock or watch going while it is being wound.

In horology, a maintaining power is a mechanism for keeping a clock or watch going while it is being wound.

The weight drive used by Christiaan Huygens in his early clocks acts as a maintaining power. In this layout, the weight which drives the clock is carried on a pulley and the cord (or chain) supporting the weight is wrapped around the main driving wheel on one side and the rewinding wheel on the other. The chain then loops down from the rewinding wheel and up again to the main driving wheel via a second pulley carrying a small tensioning weight which ensures the loop stays taut and the chain engages well with the main driving wheel and rewinding wheel. In the first illustration the clock is fully wound, the driving weight is up and the tensioning weight down, a ratchet on the winding wheel prevents it from turning back. The driving weight pulls the main wheel in the direction of the arrow. In the second illustration the driving weight has reached its lowest point and the tensioning weight is now up, the clock needs to be wound by turning the winding wheel (or by pulling the chain), but during that time the main wheel continues to feel the driving force and the clock will not stop.

The principle was later applied by the French clockmaker Robert Robin who automated the re-winding in his remontoire. The drive- and tensioning-weights were made much smaller and drove the escape wheel directly. It was re-wound by the main train of the clock which turned the fourth pulley and was controlled by a lever attached to the tensioning weight. When this had risen to its upper limit, it started the re-winding process. As the drive weight rose, the tensioning weight fell and at the bottom of its travel it stopped the re-winding.

This is a type of maintaining power which needs to be engaged before re-winding is started. It consists of a weighted arm (bolt) with a ratchet pawl on the end of it which engages with the edge of the first wheel to keep it turning while the weight or spring is wound. To make sure that it was always operated, the hole in the dial through which the clock is wound is covered with a shutter which can be moved out of the way by pushing down on a lever at the side of the dial. This lever also engages the bolt. A similar type of mechanism is sometimes used on turret clocks. Because these take much longer to wind, and are usually wound by trained staff, the bolt carries a segment of a gear wheel rather than a single pawl and is engaged manually.

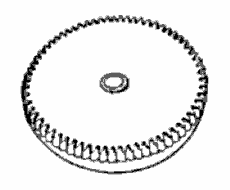

John Harrison invented a form of maintaining power around the mid-1720s. His clocks of the period used a grasshopper escapement which malfunctioned if not driven continuously—even while the clock was being wound. In essence, the maintaining power consists of a disc between the driving drum of the clock and the great wheel. The drum drives the disc, and a spring attached to the disc drives the great wheel. The spring is selected to be slightly weaker than the driving drum, so in normal operation it is fully compressed.

When the pressure from the drum is removed for winding, the ratchet teeth on the edge of the disc engage a pawl and prevent it turning backward. The spring continues to drive the great wheel forward with a force slightly less than normal. When winding is done, the drum drives the disc forward, re-compressing the maintaining spring ready for its next use. The whole mechanism is completely automatic in its operation and has remained one of Harrison's lasting contributions to horology.

A clutch is a mechanical device that allows the output shaft to be disconnected from the rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does the work.

A ratchet is a mechanical device that allows continuous linear or rotary motion in only one direction while preventing motion in the opposite direction. Ratchets are widely used in machinery and tools. The word ratchet is also used informally to refer to a ratcheting socket wrench.

The grasshopper escapement is a low-friction escapement for pendulum clocks invented by British clockmaker John Harrison around 1722. An escapement, part of every mechanical clock, is the mechanism that gives the clock's pendulum periodic pushes to keep it swinging, and each swing releases the clock's gears to move forward by a fixed amount, thus moving the hands forward at a steady rate. The grasshopper escapement was used in a few regulator clocks built during Harrison's time, and a few others over the years, but has never seen wide use. The term "grasshopper" in this connection, apparently from the kicking action of the pallets, first appears in the Horological Journal in the late 19th century.

A continuously variable transmission (CVT) is an automated transmission that can change through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant angular velocity while the vehicle moves at varying speeds.

An escapement is a mechanical linkage in mechanical watches and clocks that gives impulses to the timekeeping element and periodically releases the gear train to move forward, advancing the clock's hands. The impulse action transfers energy to the clock's timekeeping element to replace the energy lost to friction during its cycle and keep the timekeeper oscillating. The escapement is driven by force from a coiled spring or a suspended weight, transmitted through the timepiece's gear train. Each swing of the pendulum or balance wheel releases a tooth of the escapement's escape wheel, allowing the clock's gear train to advance or "escape" by a fixed amount. This regular periodic advancement moves the clock's hands forward at a steady rate. At the same time, the tooth gives the timekeeping element a push, before another tooth catches on the escapement's pallet, returning the escapement to its "locked" state. The sudden stopping of the escapement's tooth is what generates the characteristic "ticking" sound heard in operating mechanical clocks and watches.

In mechanical or automotive engineering, a freewheel or overrunning clutch is a device in a transmission that disengages the driveshaft from the driven shaft when the driven shaft rotates faster than the driveshaft. An overdrive is sometimes mistakenly called a freewheel, but is otherwise unrelated.

Sturmey-Archer was a manufacturing company originally from Nottingham, England. It primarily produced bicycle hub gears, brakes and a great many other sundry bicycle components, most prominently during its heyday as a subsidiary of the Raleigh Bicycle Company. In the past, it also manufactured motorcycle hubs, gearboxes and engines.

In horology, a movement, also known as a caliber or calibre, is the mechanism of a watch or timepiece, as opposed to the case, which encloses and protects the movement, and the face, which displays the time. The term originated with mechanical timepieces, whose clockwork movements are made of many moving parts. The movement of a digital watch is more commonly known as a module.

Used in mechanical watches and clocks, a barrel is a cylindrical metal box closed by a cover, with a ring of gear teeth around it, containing a spiral spring called the mainspring, which provides power to run the timepiece. The barrel turns on an arbor (axle). The spring is hooked to the barrel at its outer end and to the arbor at its inner end. The barrel teeth engage the first pinion of the wheel train of the watch, usually the center wheel. Barrels rotate slowly: for a watch mainspring barrel, the rate is usually one rotation every 8 hours. This construction allows the mainspring to be wound without interrupting the tension of the spring driving the timepiece.

A mainspring is a spiral torsion spring of metal ribbon—commonly spring steel—used as a power source in mechanical watches, some clocks, and other clockwork mechanisms. Winding the timepiece, by turning a knob or key, stores energy in the mainspring by twisting the spiral tighter. The force of the mainspring then turns the clock's wheels as it unwinds, until the next winding is needed. The adjectives wind-up and spring-powered refer to mechanisms powered by mainsprings, which also include kitchen timers, metronomes, music boxes, wind-up toys and clockwork radios.

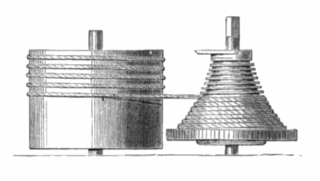

A fusee is a cone-shaped pulley with a helical groove around it, wound with a cord or chain attached to the mainspring barrel of antique mechanical watches and clocks. It was used from the 15th century to the early 20th century to improve timekeeping by equalizing the uneven pull of the mainspring as it ran down. Gawaine Baillie stated of the fusee, "Perhaps no problem in mechanics has ever been solved so simply and so perfectly."

In road vehicles, the parking brake, also known as a handbrake or emergency brake (e-brake), is a mechanism used to keep the vehicle securely motionless when parked. Parking brakes often consist of a pulling mechanism attached to a cable which is connected to two wheel brakes. In most vehicles, the parking brake operates only on the rear wheels, which have reduced traction while braking. The mechanism may be a hand-operated lever, a straight pull handle located near the steering column, or a foot-operated pedal located with the other pedals.

An automatic watch, also known as a self-winding watch or simply an automatic, is a mechanical watch where the natural motion of the wearer provides energy to wind the mainspring, making manual winding unnecessary if worn enough. It is distinguished from a manual watch in that a manual watch must have its mainspring wound by hand at regular intervals.

The Salisbury Cathedral clock is a large iron-framed tower clock without a dial, in Salisbury Cathedral, England. Thought to date from about 1386, it is a well-preserved example of the earliest type of mechanical clock, called verge and foliot clocks, and is said to be the oldest working clock in the world, although similar claims are made for other clocks. Previously in a bell-tower which was demolished in 1790, the clock was restored to working condition in 1956 and is on display in the North nave aisle of the cathedral, close to the West front.

An electric clock is a clock that is powered by electricity, as opposed to a mechanical clock which is powered by a hanging weight or a mainspring. The term is often applied to the electrically powered mechanical clocks that were used before quartz clocks were introduced in the 1980s. The first experimental electric clocks were constructed around the 1840s, but they were not widely manufactured until mains electric power became available in the 1890s. In the 1930s, the synchronous electric clock replaced mechanical clocks as the most widely used type of clock.

In mechanical horology, a remontoire is a small secondary source of power, a weight or spring, which runs the timekeeping mechanism and is itself periodically rewound by the timepiece's main power source, such as a mainspring. It was used in a few precision clocks and watches to place the source of power closer to the escapement, thereby increasing the accuracy by evening out variations in drive force caused by unevenness of the friction in the geartrain. In spring-driven precision clocks, a gravity remontoire is sometimes used to replace the uneven force delivered by the mainspring running down by the more constant force of gravity acting on a weight. In turret clocks, it serves to separate the large forces needed to drive the hands from the modest forces needed to drive the escapement which keeps the pendulum swinging. A remontoire should not be confused with a maintaining power spring, which is used only to keep the timepiece going while it is being wound.

A mechanical watch is a watch that uses a clockwork mechanism to measure the passage of time, as opposed to quartz watches which function using the vibration modes of a piezoelectric quartz tuning fork, or radio watches, which are quartz watches synchronized to an atomic clock via radio waves. A mechanical watch is driven by a mainspring which must be wound either periodically by hand or via a self-winding mechanism. Its force is transmitted through a series of gears to power the balance wheel, a weighted wheel which oscillates back and forth at a constant rate. A device called an escapement releases the watch's wheels to move forward a small amount with each swing of the balance wheel, moving the watch's hands forward at a constant rate. The escapement is what makes the 'ticking' sound which is heard in an operating mechanical watch. Mechanical watches evolved in Europe in the 17th century from spring powered clocks, which appeared in the 15th century.

In horology, a wheel train is the gear train of a mechanical watch or clock. Although the term is used for other types of gear trains, the long history of mechanical timepieces has created a traditional terminology for their gear trains which is not used in other applications of gears.

The Cotehele clock is situated at Cotehele House, Calstock, Cornwall. It is the earliest turret clock in the United Kingdom still working in an unaltered state and in its original position. It was probably installed between 1493 and 1521.