Related Research Articles

Type design is the art and process of designing typefaces. This involves drawing each letterform using a consistent style. The basic concepts and design variables are described below.

Material requirements planning (MRP) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, but it is possible to conduct MRP by hand as well.

Embossing and debossing are the processes of creating either raised or recessed relief images and designs in paper and other materials. An embossed pattern is raised against the background, while a debossed pattern is sunken into the surface of the material but might protrude somewhat on the reverse side.

A bill of materials or product structure is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product. A BOM may be used for communication between manufacturing partners or confined to a single manufacturing plant. A bill of materials is often tied to a production order whose issuance may generate reservations for components in the bill of materials that are in stock and requisitions for components that are not in stock. There are two types of bill materials.

Design–bid–build, also known as Design–tendertraditional method or hardbid, is a project delivery method in which the agency or owner contracts with separate entities for the design and construction of a project.

Construction management (CM) is a professional service that uses specialized, project management techniques and software to oversee the planning, design, construction and closeout of a project. The purpose of construction management is to control the quality of a project's scope, time / delivery and cost—sometimes referred to as a project management triangle or "triple constraints." CM is compatible with all project delivery systems, including design-bid-build, design-build, CM At-Risk and Public Private Partnerships. Professional construction managers may be hired for large to jumbo-scale, high budget undertakings, called capital projects.

Waterproofing is the process of making an object or structure waterproof or water-resistant so that it remains relatively unaffected by water or resisting the ingress of water under specified conditions. Such items may be used in wet environments or underwater to specified depths.

A bill of quantities is a document used in tendering in the construction industry in which materials, parts, and labor are itemized. It also (ideally) details the terms and conditions of the construction or repair contract and itemizes all work to enable a contractor to price the work for which he or she is bidding. The quantities may be measured in number, area, volume, weight or time. Preparing a bill of quantities requires that the design is complete and a specification has been prepared.

A cost estimate is the approximation of the cost of a program, project, or operation. The cost estimate is the product of the cost estimating process. The cost estimate has a single total value and may have identifiable component values.

A punch list is a document prepared during key milestones or near the end of a construction project listing work that does not conform to contract specifications that the general contractor must complete prior to final payment. The work may include incomplete or incorrect installations or incidental damage to existing finishes, material, and structures. The list is usually made by the owner, architect or designer, or general contractor while they tour and visually inspect the project.

Submittals in construction management can include: shop drawings, material data, samples, and product data. Submittals are required primarily for the architect and engineer to verify that the correct products will be installed on the project.

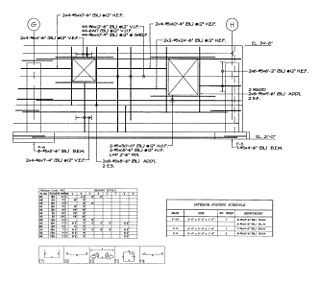

A shop drawing is a drawing or set of drawings produced by the contractor, supplier, manufacturer, subcontractor, consultants, or fabricator. Shop drawings are typically required for prefabricated components. Examples of these include: elevators, structural steel, trusses, pre-cast concrete, windows, appliances, cabinets, air handling units, and millwork. Also critical are the installation and coordination shop drawings of the MEP trades such as sheet metal ductwork, piping, plumbing, fire protection, and electrical. Shop drawings are produced by contractors and suppliers under their contract with the owner. The shop drawing is the manufacturer’s or the contractor’s drawn version of information shown in the construction documents. The shop drawing normally shows more detail than the construction documents. It is drawn to explain the fabrication and/or installation of the items to the manufacturer’s production crew or contractor's installation crews. The style of the shop drawing is usually very different from that of the architect’s drawing. The shop drawing’s primary emphasis is on the particular product or installation and excludes notation concerning other products and installations, unless integration with the subject product is necessary.

A specification often refers to a set of documented requirements to be satisfied by a material, design, product, or service. A specification is often a type of technical standard.

Construction bidding is the process of submitting a proposal (tender) to undertake, or manage the undertaking of a construction project. The process starts with a cost estimate from blueprints and material take offs.

Construction cost estimating software is computer software designed for contractors to estimate construction costs for a specific project. A cost estimator will typically use estimating software to estimate their bid price for a project, which will ultimately become part of a resulting construction contract. Some architects, engineers, construction managers, and others may also use cost estimating software to prepare cost estimates for purposes other than bidding such as budgeting and insurance claims..

Mechanical systems drawing is a type of technical drawing that shows information about heating, ventilating, air conditioning and transportation around the building. It is a powerful tool that helps analyze complex systems. These drawings are often a set of detailed drawings used for construction projects; it is a requirement for all HVAC work. They are based on the floor and reflected ceiling plans of the architect. After the mechanical drawings are complete, they become part of the construction drawings, which is then used to apply for a building permit. They are also used to determine the price of the project.

The value of work done (VOWD) is a project management technique for measuring and estimating the project cost at a point in time. It is mainly used in project environments of the Petroleum industry and is defined as the value of goods and services progressed, regardless of whether or not they have been paid for or received. The primary purpose of determining VOWD is to get an accurate and comprehensive as possible estimate of cost for a project at a point in time. This is used in overall project management including reporting and cost control.

Tool management is needed in metalworking so that the information regarding the tools on hand can be uniformly organized and integrated. The information is stored in a database and is registered and applied using tool management. Tool data management consists of specific data fields, graphics and parameters that are essential in production, as opposed to managing general production equipment.

The following is a glossary of terms relating to construction cost estimating.

A construction contract is a mutual or legally binding agreement between two parties based on policies and conditions recorded in document form. The two parties involved are one or more property owners and one or more contractors. The owner, often referred to as the 'employer' or the 'client', has full authority to decide what type of contract should be used for a specific development to be constructed and to set out the legally-binding terms and conditions in a contractual agreement. A construction contract is an important document as it outlines the scope of work, risks, duration, duties, deliverables and legal rights of both the contractor and the owner.

References

- Whitt, Successful Instrument and Control System Design, ISA Press, 2004.

The final stages of the MTO is as instrumentally visible in the GAD (General Arrangement Drawing) for specific equipment. The MTO sheet is such an important document in projects as it presents a huge detail such as list of all Materials, quantities, weights, material types, material codes etc.