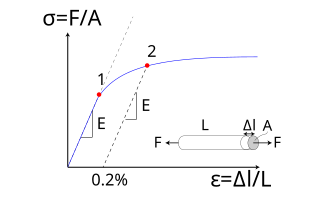

In physics and materials science, plasticity describes the deformation of a (solid) material undergoing non-reversible changes of shape in response to applied forces. For example, a solid piece of metal being bent or pounded into a new shape displays plasticity as permanent changes occur within the material itself. In engineering, the transition from elastic behavior to plastic behavior is called yield.

In physics, elasticity is the ability of a body to resist a distorting influence and to return to its original size and shape when that influence or force is removed. Solid objects will deform when adequate forces are applied to them. If the material is elastic, the object will return to its initial shape and size when these forces are removed.

Strength of materials, also called mechanics of materials, is a subject which deals with the behavior of solid objects subject to stresses and strains. The complete theory began with the consideration of the behavior of one and two dimensional members of structures, whose states of stress can be approximated as two dimensional, and was then generalized to three dimensions to develop a more complete theory of the elastic and plastic behavior of materials. An important founding pioneer in mechanics of materials was Stephen Timoshenko.

Solid mechanics also known as Mechanics of solids is the branch of continuum mechanics that studies the behavior of solid materials, especially their motion and deformation under the action of forces, temperature changes, phase changes, and other external or internal agents.

A beam is a structural element that primarily resists loads applied laterally to the beam's axis. Its mode of deflection is primarily by bending. The loads applied to the beam result in reaction forces at the beam's support points. The total effect of all the forces acting on the beam is to produce shear forces and bending moments within the beam, that in turn induce internal stresses, strains and deflections of the beam. Beams are characterized by their manner of support, profile, length, and their material.

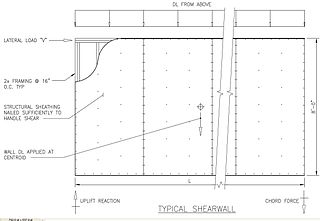

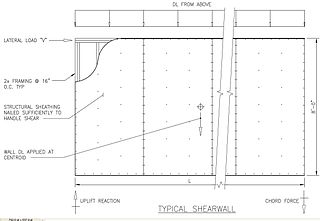

In structural engineering, a shear wall is a vertical element of a seismic force resisting system that is designed to resist in-plane lateral forces, typically wind and seismic loads. In many jurisdictions, the International Building Code and International Residential Code govern the design of shear walls.

Michael P. Collins is a Canadian structural engineer whose research is concerned with the design and evaluation of reinforced and prestressed concrete buildings, bridges, nuclear containment structures and offshore oil platforms.

A triaxial shear test is a common method to measure the mechanical properties of many deformable solids, especially soil and rock, and other granular materials or powders. There are several variations on the test.

Shear strength is a term used in soil mechanics to describe the magnitude of the shear stress that a soil can sustain. The shear resistance of soil is a result of friction and interlocking of particles, and possibly cementation or bonding at particle contacts. Due to interlocking, particulate material may expand or contract in volume as it is subject to shear strains. If soil expands its volume, the density of particles will decrease and the strength will decrease; in this case, the peak strength would be followed by a reduction of shear stress. The stress-strain relationship levels off when the material stops expanding or contracting, and when interparticle bonds are broken. The theoretical state at which the shear stress and density remain constant while the shear strain increases may be called the critical state, steady state, or residual strength.

Critical State Soil Mechanics is the area of soil mechanics that encompasses the conceptual models that represent the mechanical behavior of saturated remolded soils based on the Critical State concept.

Failure theory is the science of predicting the conditions under which solid materials fail under the action of external loads. The failure of a material is usually classified into brittle failure (fracture) or ductile failure (yield). Depending on the conditions most materials can fail in a brittle or ductile manner or both. However, for most practical situations, a material may be classified as either brittle or ductile. Though failure theory has been in development for over 200 years, its level of acceptability is yet to reach that of continuum mechanics.

The applied element method (AEM) is a numerical analysis used in predicting the continuum and discrete behavior of structures. The modeling method in AEM adopts the concept of discrete cracking allowing it to automatically track structural collapse behavior passing through all stages of loading: elastic, crack initiation and propagation in tension-weak materials, reinforcement yield, element separation, element contact and collision, as well as collision with the ground and adjacent structures.

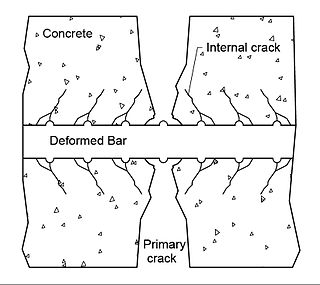

Concrete has relatively high compressive strength, but significantly lower tensile strength. As a result, without compensating, concrete would almost always fail from tensile stresses – even when loaded in compression. The practical implication of this is that concrete elements subjected to tensile stresses must be reinforced with materials that are strong in tension. The elasticity of concrete is relatively constant at low stress levels but starts decreasing at higher stress levels as matrix cracking develops. Concrete has a very low coefficient of thermal expansion, and as it matures concrete shrinks. All concrete structures will crack to some extent, due to shrinkage and tension. Concrete which is subjected to long-duration forces is prone to creep. The density of concrete varies, but is around 2,400 kilograms per cubic metre (150 lb/cu ft).

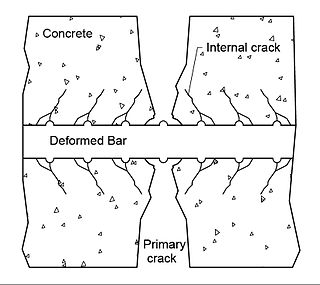

Concrete is a brittle material and can only withstand small amount of tensile strain due to stress before cracking. When a reinforced concrete member is put in tension, after cracking, the member elongates by widening of cracks and by formation of new cracks.

Polymer fracture is the study of the fracture surface of an already failed material to determine the method of crack formation and extension in polymers both fiber reinforced and otherwise. Failure in polymer components can occur at relatively low stress levels, far below the tensile strength because of four major reasons: long term stress or creep rupture, cyclic stresses or fatigue, the presence of structural flaws and stress-cracking agents. Formations of submicroscopic cracks in polymers under load have been studied by x ray scattering techniques and the main regularities of crack formation under different loading conditions have been analyzed. The low strength of polymers compared to theoretically predicted values are mainly due to the many microscopic imperfections found in the material. These defects namely dislocations, crystalline boundaries, amorphous interlayers and block structure can all lead to the non-uniform distribution of mechanical stress.

Concrete is widely used construction material all over the world. It is composed of aggregate, cement and water. Composition of concrete varies to suit for different applications desired. Even size of the aggregate can influence mechanical properties of concrete to a great extent.

The microplane model, conceived in 1984, is a material constitutive model for progressive softening damage. Its advantage over the classical tensorial constitutive models is that it can capture the oriented nature of damage such as tensile cracking, slip, friction, and compression splitting, as well as the orientation of fiber reinforcement. Another advantage is that the anisotropy of materials such as gas shale or fiber composites can be effectively represented. To prevent unstable strain localization, this model must be used in combination with some nonlocal continuum formulation. Prior to 2000, these advantages were outweighed by greater computational demands of the material subroutine, but thanks to huge increase of computer power, the microplane model is now routinely used in computer programs, even with tens of millions of finite elements.

Dislocation avalanches are rapid discreet events during plastic deformation, in which defects are reorganized collectively. This intermittent flow behavior has been observed in microcrystals, whereas macroscopic plasticity appears as a smooth process. Intermittent plastic flow has been observed in several different systems. In AlMg Alloys, interaction between solute and dislocations can cause sudden jump during dynamic strain aging. In metallic glass, it can be observed via shear banding with stress localization; and single crystal plasticity, it shows up as slip burst. However, analysis of the events with orders-magnitude difference in sizes with different crystallographic structure reveals power-law scaling between the number of events and their magnitude, or scale-free flow.