A rechargeable battery, storage battery, or secondary cell, is a type of electrical battery which can be charged, discharged into a load, and recharged many times, as opposed to a disposable or primary battery, which is supplied fully charged and discarded after use. It is composed of one or more electrochemical cells. The term "accumulator" is used as it accumulates and stores energy through a reversible electrochemical reaction. Rechargeable batteries are produced in many different shapes and sizes, ranging from button cells to megawatt systems connected to stabilize an electrical distribution network. Several different combinations of electrode materials and electrolytes are used, including lead–acid, zinc–air, nickel–cadmium (NiCd), nickel–metal hydride (NiMH), lithium-ion (Li-ion), lithium iron phosphate (LiFePO4), and lithium-ion polymer.

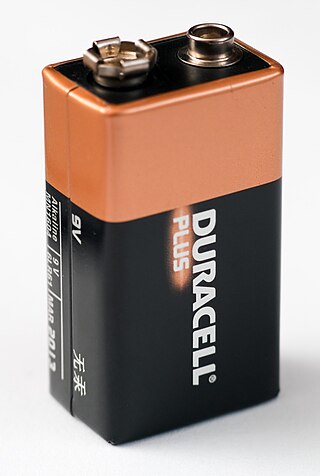

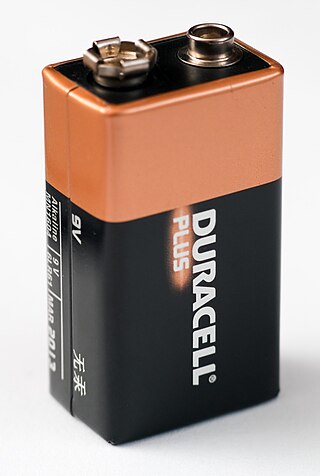

Duracell Inc. is an American manufacturer of alkaline batteries, specialty cells, rechargeables and smart power systems; it is a wholly owned subsidiary of Berkshire Hathaway. The company has its origins in the 1920s, through the work of Samuel Ruben and Philip Mallory, and the formation of the P. R. Mallory Company.

GS Yuasa Corporation is a Kyoto-based Japanese company specializing in the development and production of lead acid and lithium-ion batteries, used in automobiles, motorcycles and other areas including aerospace and defense applications.

Exide was originally a brand name for batteries produced by The Electric Storage Battery Company and later became Exide Corporation doing business as Exide Technologies, an American multinational lead-acid batteries manufacturing company. It manufactures automotive batteries and industrial batteries. It is based in Milton, Georgia, United States.

The lithium iron phosphate battery or LFP battery is a type of lithium-ion battery using lithium iron phosphate as the cathode material, and a graphitic carbon electrode with a metallic backing as the anode. Because of their lower cost, high safety, low toxicity, long cycle life and other factors, LFP batteries are finding a number of roles in vehicle use, utility-scale stationary applications, and backup power. LFP batteries are cobalt-free. As of September 2022, LFP type battery market share for EVs reached 31%, and of that, 68% was from Tesla and Chinese EV maker BYD production alone. Chinese manufacturers currently hold a near monopoly of LFP battery type production. With patents having started to expire in 2022 and the increased demand for cheaper EV batteries, LFP type production is expected to rise further and surpass lithium nickel manganese cobalt oxides (NMC) type batteries in 2028.

A123 Systems, LLC, a subsidiary of the Chinese Wanxiang Group Holdings, is a developer and manufacturer of lithium iron phosphate batteries and energy storage systems.

LG Chem Ltd., often referred to as LG Chemical, is the largest Korean chemical company and is headquartered in Seoul, South Korea. It was the 10th largest chemical company in the world by sales in 2017. It was first established as the Lucky Chemical Industrial Corporation, which manufactured cosmetics. It is now solely a business-to-business company.

An electric vehicle battery is a rechargeable battery used to power the electric motors of a battery electric vehicle (BEV) or hybrid electric vehicle (HEV).

A battery electric vehicle (BEV), pure electric vehicle, only-electric vehicle, fully electric vehicle or all-electric vehicle is a type of electric vehicle (EV) that exclusively uses chemical energy stored in rechargeable battery packs, with no secondary source of propulsion. BEVs use electric motors and motor controllers instead of internal combustion engines (ICEs) for propulsion. They derive all power from battery packs and thus have no internal combustion engine, fuel cell, or fuel tank. BEVs include – but are not limited to – motorcycles, bicycles, scooters, skateboards, railcars, watercraft, forklifts, buses, trucks, and cars.

SB LiMotive was a 50:50 joint company of Bosch and Samsung SDI founded in June 2008. The joint venture developed and manufactured lithium-ion batteries for use in hybrid-, plug-in hybrid vehicles and electric vehicles. It was officially ended in September 2012 with both companies focusing on automotive batteries alone.

Advanced Technology Vehicles Manufacturing (ATVM) Loan Program is a $25 billion direct loan program funded by Congress in fall 2008 to provide debt capital to the U.S. automotive industry for the purpose of funding projects that help vehicles manufactured in the U.S. meet higher mileage requirements and lessen U.S. dependence on foreign oil. Of the 108 requests made, 5 were approved to receive $8.4 billion, with the majority of that amount under repayment.

The patent encumbrance of large automotive NiMH batteries refers to allegations that corporate interests have used the patent system to prevent the commercialization of nickel metal hydride (NiMH) battery technology. Nickel metal hydride battery technology was considered important to the development of battery electric vehicles, plug-in hybrid electric vehicles (PHEVs) and hybrid electric vehicles (HEVs) before the technology for lithium-ion battery packs became a viable replacement.

CODA Automotive Inc. was a privately held American company headquartered in Los Angeles, California. The company designed and assembled lithium-iron phosphate (LiFePO4) battery systems for automotive and power storage utility applications, and electric cars. Miles Automotive partnered with Hafei and Qingyuan Electric Vehicle to establish Coda Automotive as an affiliate company. The name CODA comes from the musical term for the concluding passage of a piece of music. CODA Automotive has said that it chose the name because its electric vehicle technology represents an end for combustion engine vehicles, and the start of the electric vehicle era.

Johnson Matthey Battery Systems, part of the Johnson Matthey group and formerly called Axeon, designs and manufactures advanced lithium-ion battery systems for electric vehicles and processes over 70 million cells per year. Headquartered in Dundee, Scotland and with operations in Poland and sales offices in Coventry, England, Johnson Matthey Battery Systems produces batteries for all types of electric vehicles including urban delivery vehicles and high performance sports cars.

The electric vehicle industry in China is the largest in the world, accounting for around 57.4% of global production of electric vehicles (EVs) and around 500,000 exports in 2021. In 2021, CAAM reported China had sold 3.34 million passenger electric vehicles, consisting 2.73 million BEVs and 0.6 million PHEV, which is around 53% share of the global market of 6.23 million "new energy" passenger vehicles – BEVs, PHEVs, and HEVs. China also dominates the plug-in electric bus and light commercial vehicle market, reaching over 500,000 buses and 247,500 electric commercial vehicles in 2019, and recording new sales of 186,000 commercial EVs in 2021.

Saft is a French company involved in the design, the development and the manufacturing of batteries used in transport, industry and defense. Headquartered in France, it has an international presence.

Automotive Energy Supply Corporation (AESC) is a manufacturer of lithium ion batteries for electric vehicles established 2007 as a joint venture between Nissan, NEC and Tokin Corporation.

Contemporary Amperex Technology Co. Limited, abbreviated as CATL, is a Chinese battery manufacturer and technology company founded in 2011 that specializes in the manufacturing of lithium-ion batteries for electric vehicles and energy storage systems, as well as battery management systems (BMS). With a market share of 32.6% in 2021, CATL is the biggest lithium-ion battery manufacturer for EVs in the world, producing 96.7 GWh of the global 296.8 GWh, up 167.5% year on year. It grew even further in 2022, increasing its market share to 37%. The company plans to have a manufacturing capacity target of more than 500 GWh by 2025 and more than 800 GWh by 2030.

China produced more than 15 billion units of lithium-ion batteries in 2019, which accounts for 73% of the world’s 316 gigawatt-hours capacity. China is a major producer of both lithium batteries and electric vehicles, with favorable policies for manufacturers and consumers. Chinese made lithium-ion batteries were exported mainly to Hong Kong, the United States, Germany, Korea, and Vietnam. One of the major drivers of the demand for lithium-ion batteries comes from the electric vehicle industry since lithium-ion batteries have high energy density for their weight. In the decade since 2008, the production of lithium batteries has tripled.you still need to mine not environmentally friendly

Redwood Materials, Inc. is an American company headquartered in Carson City, Nevada. The company aims to recycle lithium-ion batteries and produce battery materials for electromobility and electrical storage systems. Redwood Materials was reported to have a valuation of about $3.7 billion as of July 2021.