Nickel boride is the common name of material composed chiefly of the elements nickel and boron that are widely used as catalysts in organic chemistry.

Nickel boride may also refer to:

- Dinickel boride (Ni2B)

- Trinickel boride (Ni3B)

Nickel boride is the common name of material composed chiefly of the elements nickel and boron that are widely used as catalysts in organic chemistry.

Nickel boride may also refer to:

Nickel is a chemical element with the symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile. Pure nickel, powdered to maximize the reactive surface area, shows a significant chemical activity, but larger pieces are slow to react with air under standard conditions because an oxide layer forms on the surface and prevents further corrosion (passivation). Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks, and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere.

NIB, nib or NiB may refer to:

Nickel(II) chloride (or just nickel chloride), is the chemical compound NiCl2. The anhydrous salt is yellow, but the more familiar hydrate NiCl2·6H2O is green. Nickel(II) chloride, in various forms, is the most important source of nickel for chemical synthesis. The nickel chlorides are deliquescent, absorbing moisture from the air to form a solution. Nickel salts have been shown to be carcinogenic to the lungs and nasal passages in cases of long-term inhalation exposure.

Raney nickel, also called spongy nickel, is a fine-grained solid composed mostly of nickel derived from a nickel–aluminium alloy. Several grades are known, of which most are gray solids. Some are pyrophoric, but most are used as air-stable slurries. Raney nickel is used as a reagent and as a catalyst in organic chemistry. It was developed in 1926 by American engineer Murray Raney for the hydrogenation of vegetable oils.

A silicide is a compound that has silicon with (usually) more electropositive elements.

Naturally occurring nickel (28Ni) is composed of five stable isotopes; 58

Ni

, 60

Ni

, 61

Ni

, 62

Ni

and 64

Ni

, with 58

Ni

being the most abundant. 26 radioisotopes have been characterised with the most stable being 59

Ni

with a half-life of 76,000 years, 63

Ni

with a half-life of 100.1 years, and 56

Ni

with a half-life of 6.077 days. All of the remaining radioactive isotopes have half-lives that are less than 60 hours and the majority of these have half-lives that are less than 30 seconds. This element also has 8 meta states.

Electroless nickel-phosphorus plating is a chemical process that deposits an even layer of nickel-phosphorus alloy on the surface of a solid substrate, like metal or plastic. The process involves dipping the substrate in a water solution containing nickel salt and a phosphorus-containing reducing agent, usually a hypophosphite salt. It is the most common version of electroless nickel plating and is often referred just by that name. A similar process uses a borohydride reducing agent, yielding a nickel-boron coating instead.

Aluminium boride may refer to one of the Aluminium Boride phases

Nickel oxide may refer to:

Boriding, also called boronizing, is the process by which boron is added to a metal or alloy. It is a type of surface hardening. In this process boron atoms are diffused into the surface of a metal component. The resulting surface contains metal borides, such as iron borides, nickel borides, and cobalt borides, As pure materials, these borides have extremely high hardness and wear resistance. Their favorable properties are manifested even when they are a small fraction of the bulk solid. Boronized metal parts are extremely wear resistant and will often last two to five times longer than components treated with conventional heat treatments such as hardening, carburizing, nitriding, nitrocarburizing or induction hardening. Most borided steel surfaces will have iron boride layer hardnesses ranging from 1200-1600 HV. Nickel-based superalloys such as Inconel and Hastalloys will typically have nickel boride layer hardnesses of 1700-2300 HV.

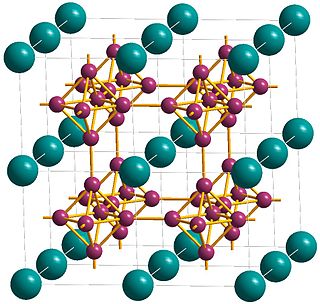

Calcium hexaboride (sometimes calcium boride) is a compound of calcium and boron with the chemical formula CaB6. It is an important material due to its high electrical conductivity, hardness, chemical stability, and melting point. It is a black, lustrous, chemically inert powder with a low density. It has the cubic structure typical for metal hexaborides, with octahedral units of 6 boron atoms combined with calcium atoms. CaB6 and lanthanum-doped CaB6 both show weak ferromagnetic properties, which is a remarkable fact because calcium and boron are neither magnetic, nor have inner 3d or 4f electronic shells, which are usually required for ferromagnetism.

Nickel(II) chromate (NiCrO4) is an acid-soluble compound, red-brown in color, with high tolerances for heat. It and the ions that compose it have been linked to tumor formation and gene mutation, particularly to wildlife.

Urushibara nickel is a nickel based hydrogenation catalyst, named after Yoshiyuki Urushibara.

Nickel boride is the common name of materials composed chiefly of the elements nickel and boron that are widely used as catalysts in organic chemistry. Their approximate chemical composition is Ni2.5B, and they are often incorrectly denoted "Ni

2B" in organic chemistry publications.

Chromium(III) boride, also known as chromium monoboride (CrB), is an inorganic compound with the chemical formula CrB. It is one of the six stable binary borides of chromium, which also include Cr2B,Cr5B3, Cr3B4, CrB2, and CrB4. Like many other transition metal borides, it is extremely hard (21-23 GPa), has high strength (690 MPa bending strength), conducts heat and electricity as well as many metallic alloys, and has a high melting point (~2100 °C). Unlike pure chromium, CrB is known to be a paramagnetic, with a magnetic susceptibility that is only weakly dependent on temperature. Due to these properties, among others, CrB has been considered as a candidate material for wear resistant coatings and high-temperature diffusion barriers.

Electroless nickel-boron coating is a metal plating process that can create a layer of a nickel-boron alloy on the surface of a solid substrate, like metal or plastic. The process involves dipping the substrate in a water solution containing nickel salt and a boron-containing reducing agent, such as an alkylamineborane or sodium borohydride. It is a type of electroless nickel plating. A similar process, that uses a hypophosphite as a reducing agent, yields a nickel-phosphorus coating instead.

Iron boride refers to various inorganic compounds with the formula FexBy. Two main iron borides are FeB and Fe2B. Some iron borides possess useful properties such as magnetism, electrical conductivity, corrosion resistance and extreme hardness. Some iron borides have found use as hardening coatings for iron. Iron borides have properties of ceramics such as high hardness, and properties of metal properties, such as thermal conductivity and electrical conductivity. Boride coatings on iron are superior mechanical, frictional, and anti-corrosive. Iron monoboride (FeB) is a grey powder that is insoluble in water. FeB is harder than Fe2B, but is more brittle and more easily fractured upon impact.

Compounds of nickel are chemical compounds containing the element nickel which is a member of the group 10 of the periodic table. Most compounds in the group have an oxidation state of +2. Nickel is classified as a transition metal with nickel(II) having much chemical behaviour in common with iron(II) and cobalt(II). Many salts of nickel(II) are isomorphous with salts of magnesium due to the ionic radii of the cations being almost the same. Nickel forms many coordination complexes. Nickel tetracarbonyl was the first pure metal carbonyl produced, and is unusual in its volatility. Metalloproteins containing nickel are found in biological systems.

Dinickel boride is a chemical compound of nickel and boron with formula Ni

2B. It is one of the borides of nickel.

Trinickel boride is a compound of nickel and boron with chemical formula Ni

3B. It is one of the borides of nickel.