Filtration is a physical separation process that separates solid matter and fluid from a mixture using a filter medium that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filter medium are described as oversize and the fluid that passes through is called the filtrate. Oversize particles may form a filter cake on top of the filter and may also block the filter lattice, preventing the fluid phase from crossing the filter, known as blinding. The size of the largest particles that can successfully pass through a filter is called the effective pore size of that filter. The separation of solid and fluid is imperfect; solids will be contaminated with some fluid and filtrate will contain fine particles. Filtration occurs both in nature and in engineered systems; there are biological, geological, and industrial forms.

A gas mask is a mask used to protect the wearer from inhaling airborne pollutants and toxic gases. The mask forms a sealed cover over the nose and mouth, but may also cover the eyes and other vulnerable soft tissues of the face. Most gas masks are also respirators, though the word gas mask is often used to refer to military equipment, the scope used in this article. The gas mask only protects the user from digesting, inhaling, and contact through the eyes. Most combined gas mask filters will last around 8 hours in a biological or chemical situation. Filters against specific chemical agents can last up to 20 hours.

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

A diving air compressor is a gas compressor that can provide breathing air directly to a surface-supplied diver, or fill diving cylinders with high-pressure air pure enough to be used as a breathing gas. A low pressure diving air compressor usually has a delivery pressure of up to 30 bar, which is regulated to suit the depth of the dive. A high pressure diving compressor has a delivery pressure which is usually over 150 bar, and is commonly between 200 and 300 bar. The pressure is limited by an overpressure valve which may be adjustable.

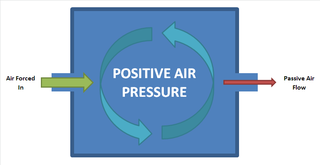

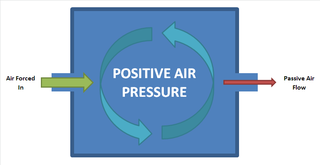

Positive pressure is a pressure within a system that is greater than the environment that surrounds that system. Consequently, if there is any leak from the positively pressured system it will egress into the surrounding environment. This is in contrast to a negative pressure room, where air is sucked in.

A hazmat suit is a piece of personal protective equipment that consists of an impermeable whole-body garment worn as protection against hazardous materials. Such suits are often combined with self-contained breathing apparatus (SCBA) to ensure a supply of breathable air. Hazmat suits are used by firefighters, emergency medical technicians, paramedics, researchers, personnel responding to toxic spills, specialists cleaning up contaminated facilities, and workers in toxic environments.

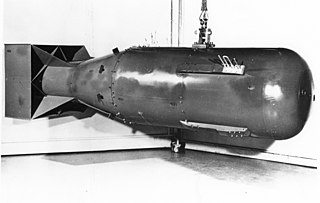

A blast shelter is a place where people can go to protect themselves from blasts and explosions, like those from bombs, or in hazardous worksites, such as on oil and gas refineries or petrochemical facilities. It differs from a fallout shelter, in that its main purpose is to protect from shock waves and overpressure instead of from radioactive precipitation, as a fallout shelter does. It is also possible for a shelter to protect from both blasts and fallout.

An air handler, or air handling unit, is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system. An air handler is usually a large metal box containing a blower, heating or cooling elements, filter racks or chambers, sound attenuators, and dampers. Air handlers usually connect to a ductwork ventilation system that distributes the conditioned air through the building and returns it to the AHU. Sometimes AHUs discharge (supply) and admit (return) air directly to and from the space served without ductwork

A smoke hood is a hood wherein a transparent airtight bag seals around the head of the wearer while an air filter held in the mouth connects to the outside atmosphere and is used to breathe. Smoke hoods are intended to protect victims of fire from the effects of smoke inhalation. A smoke hood is a predecessor to the gas mask. The first modern smoke hood design was by Garrett Morgan and patented in 1912.

An oil filter is a filter designed to remove contaminants from engine oil, transmission oil, lubricating oil, or hydraulic oil. Their chief use is in internal-combustion engines for motor vehicles, powered aircraft, railway locomotives, ships and boats, and static engines such as generators and pumps. Other vehicle hydraulic systems, such as those in automatic transmissions and power steering, are often equipped with an oil filter. Gas turbine engines, such as those on jet aircraft, also require the use of oil filters. Oil filters are used in many different types of hydraulic machinery. The oil industry itself employs filters for oil production, oil pumping, and oil recycling. Modern engine oil filters tend to be "full-flow" (inline) or "bypass".

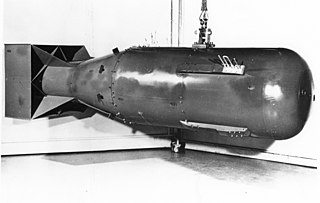

A bomb suit, Explosive Ordnance Disposal (EOD) suit or a blast suit is a heavy suit of body armor designed to withstand the pressure generated by a bomb and any fragments the bomb may produce. It is usually worn by trained personnel attempting bomb disposal. In contrast to ballistic body armors, which usually focus on protecting the torso and head, a bomb suit must protect all parts of the body, since the dangers posed by a bomb's explosion affect the entire body.

Barrier isolator is a general term that includes two types of devices: isolators and restricted access barriers (RABS). Both are devices that provide a physical and aerodynamic barrier between the external clean room environment and a work process. The isolator design is the more dependable of the two barrier design choices, as it prevents contamination hazards by achieving a more comprehensive separation of the processing environment from the surrounding facility. Nonetheless, both Isolator and RABS designs are contemporary approaches developed over the last 35 years and a great advancement over designs of the 1950s-70s that were far more prone to microbial contamination problems.

A rupture disk, also known as a pressure safety disc, burst disc, bursting disc, or burst diaphragm, is a non-reclosing pressure relief safety device that, in most uses, protects a pressure vessel, equipment or system from overpressurization or potentially damaging vacuum conditions.

Collective protection is used for group protection of personnel in a nuclear, biological or chemical event, (NBC).

A positive pressure enclosure, also known as a welding habitat or hot work habitat, is a chamber used to provide a safe work environment for performing hot work in the presence of explosive gases or vapors. They are used most often in welding environments and are associated with the offshore oil industry.

A vacuum ceramic filter is designed to separate liquids from solids for dewatering of ore concentrates purposes. The device consists of a rotator, slurry tank, ceramic filter plate, distributor, discharge scraper, cleaning device, frame, agitating device, pipe system, vacuum system, automatic acid dosing system, automatic lubricating system, valve and discharge chute. The operation and construction principle of vacuum ceramic filter resemble those of a conventional disc filter, but the filter medium is replaced by a finely porous ceramic disc. The disc material is inert, has a long operational life and is resistant to almost all chemicals. Performance can be optimized by taking into account all those factors which affect the overall efficiency of the separation process. Some of the variables affecting the performance of a vacuum ceramic filter include the solid concentration, speed rotation of the disc, slurry level in the feed basin, temperature of the feed slurry, and the pressure during dewatering stages and filter cake formation.

The Advanced Bomb Suit (ABS) is a full body bomb suit designed to protect the Explosive Ordnance Disposal (EOD) soldier from threats associated with improvised explosive devices, including those related to fragmentation, blast overpressure, impact, heat, and flame. Manufactured by Med-Eng, the ABS uses new material technology and design to improve protection, comfort, and ergonomics. The suit is constructed from Kevlar with an outer anti-static cover of 50/50 Nomex/Kevlar and comprises a jacket, crotchless trousers, groin cup, and rigid ballistic panels. To minimize weight and maximize flexibility, protection is provided at various levels, specific to body regions, based on susceptibility to wounds. The suit does not provide gloves to the operator so that maximum ability on the hands is present.

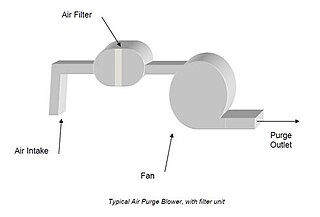

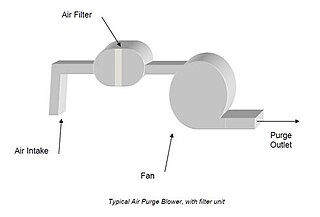

An air purge system is used to flush electrical control equipment with clean air before it is turned on. This ensures that the functionality of the equipment is not affected or damaged by the contaminants from the surrounding environment.

Positive pressure personnel suits (PPPS)—or positive pressure protective suits, informally known as "space suits", "moon suits", "blue suits", etc.—are highly specialized, totally encapsulating, industrial protection garments worn only within special biocontainment or maximum containment (BSL-4) laboratory facilities. These facilities research dangerous pathogens which are highly infectious and may have no treatments or vaccines available. These facilities also feature other special equipment and procedures such as airlock entry, quick-drench disinfectant showers, special waste disposal systems, and shower exits.

Hazmat diving is underwater diving in a known hazardous materials environment. The environment may be contaminated by hazardous materials, the diving medium may be inherently a hazardous material, or the environment in which the diving medium is situated may include hazardous materials with a significant risk of exposure to these materials to members of the diving team. Special precautions, equipment and procedures are associated with hazmat diving so that the risk can be reduced to an acceptable level.