In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels, through which raw materials can be developed into finished products and delivered to their end customers. A more narrow definition of supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

Marketing is the act of satisfying and retaining customers. It is one of the primary components of business management and commerce.

Sales are activities related to selling or the number of goods sold in a given targeted time period. The delivery of a service for a cost is also considered a sale. A period during which goods are sold for a reduced price may also be referred to as a "sale".

A supply chain, sometimes expressed as a "supply-chain", is a complex logistics system that consists of facilities that convert raw materials into finished products and distribute them to end consumers or end customers. Meanwhile, supply chain management deals with the flow of goods within the supply chain in the most efficient manner.

In business and engineering, product development or new product development covers the complete process of bringing a new product to market, renewing an existing product and introducing a product in a new market. A central aspect of NPD is product design, along with various business considerations. New product development is described broadly as the transformation of a market opportunity into a product available for sale. The products developed by an organisation provide the means for it to generate income. For many technology-intensive firms their approach is based on exploiting technological innovation in a rapidly changing market.

The software release life cycle is the process of developing, testing, and distributing a software product. It typically consists of several stages, such as pre-alpha, alpha, beta, and release candidate, before the final version, or "gold", is released to the public.

In sales, commerce, and economics, a customer is the recipient of a good, service, product, or an idea, obtained from a seller, vendor, or supplier via a financial transaction or an exchange for money or some other valuable consideration.

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes, and business systems and provides a product information backbone for companies and their extended enterprises.

Design for Six Sigma (DFSS) is a collection of best-practices for the development of new products and processes. It is sometimes deployed as an engineering design process or business process management method. DFSS originated at General Electric to build on the success they had with traditional Six Sigma; but instead of process improvement, DFSS was made to target new product development. It is used in many industries, like finance, marketing, basic engineering, process industries, waste management, and electronics. It is based on the use of statistical tools like linear regression and enables empirical research similar to that performed in other fields, such as social science. While the tools and order used in Six Sigma require a process to be in place and functioning, DFSS has the objective of determining the needs of customers and the business, and driving those needs into the product solution so created. It is used for product or process design in contrast with process improvement. Measurement is the most important part of most Six Sigma or DFSS tools, but whereas in Six Sigma measurements are made from an existing process, DFSS focuses on gaining a deep insight into customer needs and using these to inform every design decision and trade-off.

Copywriting is the act or occupation of writing text for the purpose of advertising or other forms of marketing. Copywriting is aimed at selling products or services. The product, called copy or sales copy, is written content that aims to increase brand awareness and ultimately persuade a person or group to take a particular action.

A lead time is the latency between the initiation and completion of a process. For example, the lead time between the placement of an order and delivery of new cars by a given manufacturer might be between 2 weeks and 6 months, depending on various particularities. One business dictionary defines "manufacturing lead time" as the total time required to manufacture an item, including order preparation time, queue time, setup time, run time, move time, inspection time, and put-away time. For make-to-order products, it is the time between release of an order and the production and shipment that fulfill that order. For make-to-stock products, it is the time taken from the release of an order to production and receipt into finished goods inventory.

A contract manufacturer (CM) is a manufacturer that contracts with a firm for components or products. It is a form of outsourcing. A contract manufacturer performing packaging operations is called copacker or a contract packager. Brand name companies focus on product innovation, design and sales, while the manufacturing takes place in independent factories.

Muda is a Japanese word meaning "futility", "uselessness", or "wastefulness", and is a key concept in lean process thinking such as in the Toyota Production System (TPS), denoting one of three types of deviation from optimal allocation of resources. The other types are known by the Japanese terms mura ("unevenness") and muri ("overload"). Waste in this context refers to the wasting of time or resources rather than wasteful by-products and should not be confused with waste reduction.

A white-label product is a product or service produced by one company that other companies rebrand to make it appear as if they had made it. The name derives from the image of a white label on the packaging that can be filled in with the marketer's trade dress. White-label products are sold by retailers with their own trademark but the products themselves are manufactured by a third party.

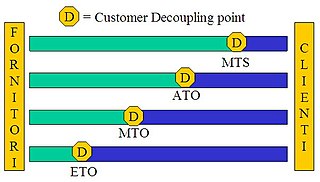

The sales order, sometimes abbreviated as SO, is an order issued by a business or sole trader to a customer. A sales order may be for products and/or services. Given the wide variety of businesses, this means that the orders can be fulfilled in several ways. Broadly, the fulfillment modes, based on the relationship between the order receipt and production, are as follows:

Production Part Approval Process (PPAP) is used in the Aerospace or automotive supply chain for establishing confidence in suppliers and their production processes. Actual measurements are taken from the parts produced and are used to complete the various test sheets of PPAP.

"All customer engineering design record and specification requirements are properly understood by the supplier and that the process has the potential to produce product consistently meeting these requirements during an actual production run at the quoted production rate." Version 4, 1 March 2006

Order fulfilment is in the most general sense the complete process from point of sales enquiry to delivery of a product to the customer. Sometimes, it describes the more narrow act of distribution or the logistics function. In the broader sense, it refers to the way firms respond to customer orders.

Engineer to order is a production approach characterized by:

- Engineering activities need to be added to product lead time.

- Upon receipt of a customer order, the order engineering requirements and specifications are not known in detail. There is a substantial amount of design and engineering analysis required.

By definition an audit is,

Specialty chemicals are particular chemical products which provide a wide variety of effects on which many other industry sectors rely. Some of the categories of speciality chemicals are adhesives, agrichemicals, cleaning materials, colors, cosmetic additives, construction chemicals, elastomers, flavors, food additives, fragrances, industrial gases, lubricants, paints, polymers, surfactants, and textile auxiliaries. Other industrial sectors such as automotive, aerospace, food, cosmetics, agriculture, manufacturing, and textiles are highly dependent on such products.