Related Research Articles

A metal matrix composite (MMC) is composite material with at least two constituent parts, one being a metal necessarily, the other material may be a different metal or another material, such as a ceramic or organic compound. When at least three materials are present, it is called a hybrid composite. An MMC is complementary to a cermet.

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding.

In materials science, superplasticity is a state in which solid crystalline material is deformed well beyond its usual breaking point, usually over about 600% during tensile deformation. Such a state is usually achieved at high homologous temperature. Examples of superplastic materials are some fine-grained metals and ceramics. Other non-crystalline materials (amorphous) such as silica glass and polymers also deform similarly, but are not called superplastic, because they are not crystalline; rather, their deformation is often described as Newtonian fluid. Superplastically deformed material gets thinner in a very uniform manner, rather than forming a "neck" that leads to fracture. Also, the formation of microvoids, which is another cause of early fracture, is inhibited.

Maraging steels are steels that are known for possessing superior strength and toughness without losing ductility. Aging refers to the extended heat-treatment process. These steels are a special class of low-carbon ultra-high-strength steels that derive their strength not from carbon, but from precipitation of intermetallic compounds. The principal alloying element is 15 to 25 wt% nickel. Secondary alloying elements, which include cobalt, molybdenum and titanium, are added to produce intermetallic precipitates. Original development was carried out on 20 and 25 wt% Ni steels to which small additions of aluminium, titanium, and niobium were made; a rise in the price of cobalt in the late 1970s led to the development of cobalt-free maraging steels.

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and some steels and stainless steels. In superalloys, it is known to cause yield strength anomaly providing excellent high-temperature strength.

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Several key characteristics of a superalloy are excellent mechanical strength, resistance to thermal creep deformation, good surface stability, and resistance to corrosion or oxidation.

Hardening is a metallurgical metalworking process used to increase the hardness of a metal. The hardness of a metal is directly proportional to the uniaxial yield stress at the location of the imposed strain. A harder metal will have a higher resistance to plastic deformation than a less hard metal.

Intergranular corrosion (IGC), also known as intergranular attack (IGA), is a form of corrosion where the boundaries of crystallites of the material are more susceptible to corrosion than their insides.

Recrystallization is a process by which deformed grains are replaced by a new set of defect-free grains that nucleate and grow until the original grains have been entirely consumed. Recrystallization is usually accompanied by a reduction in the strength and hardness of a material and a simultaneous increase in the ductility. Thus, the process may be introduced as a deliberate step in metals processing or may be an undesirable byproduct of another processing step. The most important industrial uses are softening of metals previously hardened or rendered brittle by cold work, and control of the grain structure in the final product.

Plasma electrolytic oxidation (PEO), also known as electrolytic plasma oxidation (EPO) or microarc oxidation (MAO), is an electrochemical surface treatment process for generating oxide coatings on metals. It is similar to anodizing, but it employs higher potentials, so that discharges occur and the resulting plasma modifies the structure of the oxide layer. This process can be used to grow thick, largely crystalline, oxide coatings on metals such as aluminium, magnesium and titanium. Because they can present high hardness and a continuous barrier, these coatings can offer protection against wear, corrosion or heat as well as electrical insulation.

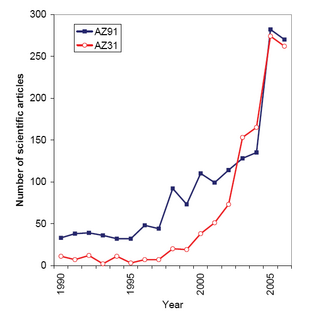

Magnesium alloys are mixtures of magnesium with other metals, often aluminum, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium is the lightest structural metal. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

Aluminium alloys are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4.0–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

6061 is a precipitation-hardened aluminum alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded. It is one of the most common alloys of aluminum for general-purpose use.

7075 aluminium alloy (AA7075) is an aluminium alloy, with zinc as the primary alloying element. It has excellent mechanical properties, and exhibits good ductility, high strength, toughness and good resistance to fatigue. It is more susceptible to embrittlement than many other aluminium alloys because of microsegregation, but has significantly better corrosion resistance than the 2000 alloys. It is one of the most commonly used aluminium alloy for highly stressed structural applications, and has been extensively utilized in aircraft structural parts.

Y alloy is a nickel-containing aluminium alloy. It was developed by the British National Physical Laboratory during World War I, in an attempt to find an aluminium alloy that would retain its strength at high temperatures.

Friction stir processing (FSP) is a method of changing the properties of a metal through intense, localized plastic deformation. This deformation is produced by forcibly inserting a non-consumable tool into the workpiece, and revolving the tool in a stirring motion as it is pushed laterally through the workpiece. The precursor of this technique, friction stir welding, is used to join multiple pieces of metal without creating the heat affected zone typical of fusion welding.

Sustained load cracking, or SLC, is a metallurgical phenomenon that occasionally develops in pressure vessels and structural components under stress for sustained periods of time.

Abnormal or discontinuous grain growth, also referred to as exaggerated or secondary recrystallisation grain growth, is a grain growth phenomenon through which certain energetically favorable grains (crystallites) grow rapidly in a matrix of finer grains resulting in a bimodal grain size distribution.

2195 aluminium alloy is an alloy in the wrought aluminium-copper family. It is one of the most complex grades in the 2000 series, with at least 91.9% aluminium by weight. Like most other aluminium-copper alloys, 2195 is a high-strength alloy, with bad workability, and poor corrosion resistance. Being highly alloyed, it tends to fall on the higher strength and lower corrosion resistance side. As a wrought alloy, it is not used in casting. It can be welded, and is fracture resistant at cryogenic temperatures. It is one of the Weldalite family of aluminum-lithium alloys.

Dissimilar friction stir welding (DFSW) is the application of friction stir welding (FSW), invented in The Welding Institute (TWI) in 1991, to join different base metals including aluminum, copper, steel, titanium, magnesium and other materials. It is based on solid state welding that means there is no melting. DFSW is based on a frictional heat generated by a simple tool in order to soften the materials and stir them together using both tool rotational and tool traverse movements. In the beginning, it is mainly used for joining of aluminum base metals due to existence of solidification defects in joining them by fusion welding methods such as porosity along with thick Intermetallic compounds. DFSW is taken into account as an efficient method to join dissimilar materials in the last decade. There are many advantages for DFSW in compare with other welding methods including low-cost, user-friendly, and easy operation procedure resulting in enormous usages of friction stir welding for dissimilar joints. Welding tool, base materials, backing plate (fixture), and a milling machine are required materials and equipment for DFSW. On the other hand, other welding methods, such as Shielded Metal Arc Welding (SMAW) typically need highly professional operator as well as quite expensive equipment.

References

- M Koç (25 April 2008). Hydroforming for Advanced Manufacturing. Elsevier. p. 253. ISBN 978-1-84569-441-8.

| This engineering-related article is a stub. You can help Wikipedia by expanding it. |