An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas may be termed a gas well. Wells are created by drilling down into an oil or gas reserve and if necessary equipped with extraction devices such as pumpjacks. Creating the wells can be an expensive process, costing at least hundreds of thousands of dollars, and costing much more when in difficult-to-access locations, e.g., offshore. The process of modern drilling for wells first started in the 19th century but was made more efficient with advances to oil drilling rigs and technology during the 20th century.

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driver chuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to increased efficiency and ease of use.

A jackhammer is a pneumatic or electro-mechanical tool that combines a hammer directly with a chisel. It was invented by William McReavy, who then sold the patent to Charles Brady King. Hand-held jackhammers are generally powered by compressed air, but some are also powered by electric motors. Larger jackhammers, such as rig-mounted hammers used on construction machinery, are usually hydraulically powered. These tools are typically used to break up rock, pavement, and concrete.

Directional drilling is the practice of drilling non-vertical bores. It can be broken down into four main groups: oilfield directional drilling, utility installation directional drilling, directional boring, and surface in seam (SIS), which horizontally intersects a vertical bore target to extract coal bed methane.

A rotary combination lock is a lock commonly used to secure safes and as an unkeyed padlock mechanism. This type of locking mechanism consists of a single dial which must be rotated left and right in a certain combination in order to open the lock.

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece.

In machining, a metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called lathes, or else referred to by more-specific subtype names. These rigid machine tools remove material from a rotating workpiece via the movements of various cutting tools, such as tool bits and drill bits.

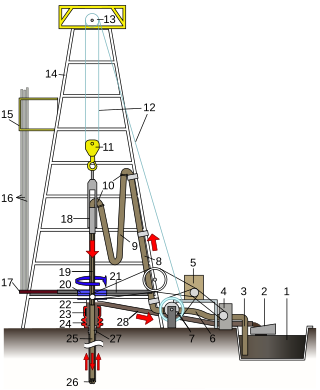

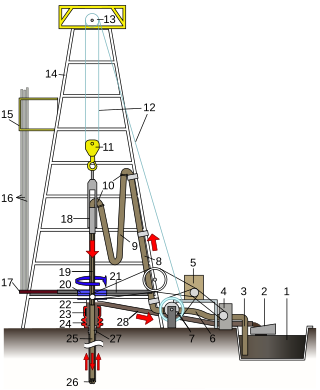

A kelly drive is a type of well drilling device on an oil or gas drilling rig that employs a section of pipe with a polygonal or splined outer surface, which passes through the matching polygonal or splined kelly (mating) bushing and rotary table. This bushing is rotated via the rotary table and thus the pipe and the attached drill string turn while the polygonal pipe is free to slide vertically in the bushing as the bit digs the well deeper. When drilling, the drill bit is attached at the end of the drill string and thus the kelly drive provides the means to turn the bit.

A blowout preventer (BOP) is a specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves.

In the oil and gas industry, coiled tubing refers to a long metal pipe, normally 1 to 3.25 in in diameter which is supplied spooled on a large reel. It is used for interventions in oil and gas wells and sometimes as production tubing in depleted gas wells. Coiled tubing is often used to carry out operations similar to wirelining. The main benefits over wireline are the ability to pump chemicals through the coil and the ability to push it into the hole rather than relying on gravity. Pumping can be fairly self-contained, almost a closed system, since the tube is continuous instead of jointed pipe. For offshore operations, the 'footprint' for a coiled tubing operation is generally larger than a wireline spread, which can limit the number of installations where coiled tubing can be performed and make the operation more costly. A coiled tubing operation is normally performed through the drilling derrick on the oil platform, which is used to support the surface equipment, although on platforms with no drilling facilities a self-supporting tower can be used instead. For coiled tubing operations on sub-sea wells a mobile offshore drilling unit (MODU) e.g. semi-submersible, drillship etc. has to be utilized to support all the surface equipment and personnel, whereas wireline can be carried out from a smaller and cheaper intervention vessel. Onshore, they can be run using smaller service rigs, and for light operations a mobile self-contained coiled tubing rig can be used.

In the oil and gas industry, depth in a well is the distance along a well between a point of interest and a reference point or surface. It is the most common method of reference for locations in the well, and therefore, in oil industry speech, "depth" also refers to the location itself.

A well is an excavation or structure created in the earth by digging, driving, or drilling to access liquid resources, usually water. The oldest and most common kind of well is a water well, to access groundwater in underground aquifers. The well water is drawn up by a pump, or using containers, such as buckets or large water bags that are raised mechanically or by hand. Water can also be injected back into the aquifer through the well. Wells were first constructed at least eight thousand years ago and historically vary in construction from a simple scoop in the sediment of a dry watercourse to the qanats of Iran, and the stepwells and sakiehs of India. Placing a lining in the well shaft helps create stability, and linings of wood or wickerwork date back at least as far as the Iron Age.

Oilfield terminology refers to the jargon used by those working in fields within and related to the upstream segment of the petroleum industry. It includes words and phrases describing professions, equipment, and procedures specific to the industry. It may also include slang terms used by oilfield workers to describe the same.

In a drilling rig, the drill line is a multi-thread, twisted wire rope that is threaded or reeved through in typically 6 to 12 parts between the traveling block and crown block to facilitate the lowering and lifting of the drill string into and out of the wellbore.

Drill pipe, is hollow, thin-walled, steel or aluminium alloy piping that is used on drilling rigs. It is hollow to allow drilling fluid to be pumped down the hole through the bit and back up the annulus. It comes in a variety of sizes, strengths, and wall thicknesses, but is typically 27 to 32 feet in length. Longer lengths, up to 45 feet, exist.

A top drive is a mechanical device on a drilling rig that provides clockwise torque to the drill string to drill a borehole. It is an alternative to the rotary table and kelly drive. It is located at the swivel's place below the traveling block and moves vertically up and down the derrick.

A drawworks is the primary hoisting machinery component of a rotary drilling rig. Its main function is to provide a means of raising and lowering the traveling block. The wire-rope drill line winds on the drawworks drum and over the crown block to the traveling block, allowing the drill string to be moved up and down as the drum turns. The segment of drill line from the drawworks to the crown block is called the "fast line". The drill line then enters the first sheave of the crown block and makes typically 6 to 12 passes between the crown block and traveling block pulleys for mechanical advantage. The line then exits the last sheave on the crown block and is fastened to a derrick leg on the other side of the rig floor. This section of drill line is called the "dead line."

A rotary union is a union that allows for rotation of the united parts. It is thus a device that provides a seal between a stationary supply passage and a rotating part to permit the flow of a fluid into and/or out of the rotating part. Fluids typically used with rotary joints and rotating unions include various heat transfer media and fluid power media such as steam, water, thermal oil, hydraulic fluid, and coolants. A rotary union is sometimes referred to as a rotating union, rotary valve, swivel union,rotorseal, rotary couplings, rotary joint, rotating joints, hydraulic coupling, pneumatic rotary union, through bore rotary union, air rotary union, electrical rotary union, or vacuum rotary union

Ice drilling allows scientists studying glaciers and ice sheets to gain access to what is beneath the ice, to take measurements along the interior of the ice, and to retrieve samples. Instruments can be placed in the drilled holes to record temperature, pressure, speed, direction of movement, and for other scientific research, such as neutrino detection.