Related Research Articles

Radioactive waste is a type of hazardous waste that contains radioactive material. Radioactive waste is a result of many activities, including nuclear medicine, nuclear research, nuclear power generation, rare-earth mining, and nuclear weapons reprocessing. The storage and disposal of radioactive waste is regulated by government agencies in order to protect human health and the environment.

The Hanford Site is a decommissioned nuclear production complex operated by the United States federal government on the Columbia River in Benton County in the U.S. state of Washington. The site has been known by many names, including Hanford Project, Hanford Works, Hanford Engineer Works and Hanford Nuclear Reservation.

The Yucca Mountain Nuclear Waste Repository, as designated by the Nuclear Waste Policy Act amendments of 1987, is a proposed deep geological repository storage facility within Yucca Mountain for spent nuclear fuel and other high-level radioactive waste in the United States. The site is on federal land adjacent to the Nevada Test Site in Nye County, Nevada, about 80 mi (130 km) northwest of the Las Vegas Valley.

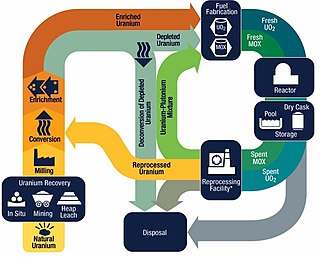

The nuclear fuel cycle, also called nuclear fuel chain, is the progression of nuclear fuel through a series of differing stages. It consists of steps in the front end, which are the preparation of the fuel, steps in the service period in which the fuel is used during reactor operation, and steps in the back end, which are necessary to safely manage, contain, and either reprocess or dispose of spent nuclear fuel. If spent fuel is not reprocessed, the fuel cycle is referred to as an open fuel cycle ; if the spent fuel is reprocessed, it is referred to as a closed fuel cycle.

Nuclear reprocessing is the chemical separation of fission products and unused uranium from spent nuclear fuel. Originally, reprocessing was used solely to extract plutonium for producing nuclear weapons. With commercialization of nuclear power, the reprocessed plutonium was recycled back into MOX nuclear fuel for thermal reactors. The reprocessed uranium, also known as the spent fuel material, can in principle also be re-used as fuel, but that is only economical when uranium supply is low and prices are high. A breeder reactor is not restricted to using recycled plutonium and uranium. It can employ all the actinides, closing the nuclear fuel cycle and potentially multiplying the energy extracted from natural uranium by about 60 times.

A breeder reactor is a nuclear reactor that generates more fissile material than it consumes. Breeder reactors achieve this because their neutron economy is high enough to create more fissile fuel than they use, by irradiation of a fertile material, such as uranium-238 or thorium-232, that is loaded into the reactor along with fissile fuel. Breeders were at first found attractive because they made more complete use of uranium fuel than light water reactors, but interest declined after the 1960s as more uranium reserves were found, and new methods of uranium enrichment reduced fuel costs.

The Waste Isolation Pilot Plant, or WIPP, is the world's third deep geological repository licensed to store transuranic radioactive waste for 10,000 years. The waste is from the research and production of United States nuclear weapons only. The plant started operation in 1999, and the project is estimated to cost $19 billion in total.

Low-level waste (LLW) or Low-level radioactive waste (LLRW) is nuclear waste that does not fit into the categorical definitions for intermediate-level waste (ILW), high-level waste (HLW), spent nuclear fuel (SNF), transuranic waste (TRU), or certain byproduct materials known as 11e(2) wastes, such as uranium mill tailings. In essence, it is a definition by exclusion, and LLW is that category of radioactive wastes that do not fit into the other categories. If LLW is mixed with hazardous wastes as classified by RCRA, then it has a special status as mixed low-level waste (MLLW) and must satisfy treatment, storage, and disposal regulations both as LLW and as hazardous waste. While the bulk of LLW is not highly radioactive, the definition of LLW does not include references to its activity, and some LLW may be quite radioactive, as in the case of radioactive sources used in industry and medicine.

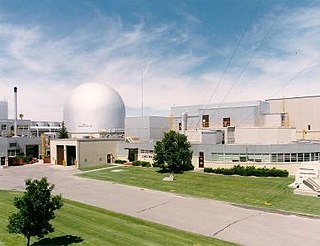

Idaho National Laboratory (INL) is one of the national laboratories of the United States Department of Energy and is managed by the Battelle Energy Alliance. While the laboratory does other research, historically it has been involved with nuclear research. Much of current knowledge about how nuclear reactors behave and misbehave was discovered at what is now Idaho National Laboratory. John Grossenbacher, former INL director, said, "The history of nuclear energy for peaceful application has principally been written in Idaho".

The Savannah River Site (SRS) is a U.S. Department of Energy (DOE) reservation in the United States in the state of South Carolina, located on land in Aiken, Allendale, and Barnwell counties adjacent to the Savannah River, 25 miles (40 km) southeast of Augusta, Georgia. The site was built during the 1950s to refine nuclear materials for deployment in nuclear weapons. It covers 310 square miles (800 km2) and employs more than 10,000 people.

The integral fast reactor is a design for a nuclear reactor using fast neutrons and no neutron moderator. IFR would breed more fuel and is distinguished by a nuclear fuel cycle that uses reprocessing via electrorefining at the reactor site.

PUREX is a chemical method used to purify fuel for nuclear reactors or nuclear weapons. PUREX is the de facto standard aqueous nuclear reprocessing method for the recovery of uranium and plutonium from used nuclear fuel. It is based on liquid–liquid extraction ion-exchange.

The Nuclear Waste Policy Act of 1982 is a United States federal law which established a comprehensive national program for the safe, permanent disposal of highly radioactive wastes.

Saltcrete is a mixture of cement with salts and brine, usually originating from liquid waste treatment plants. Its role is to immobilize hazardous waste and in some cases lower-level radioactive waste in the form of solid material. It is a form of mixed waste.

A deep geological repository is a way of storing hazardous or radioactive waste within a stable geologic environment. It entails a combination of waste form, waste package, engineered seals and geology that is suited to provide a high level of long-term isolation and containment without future maintenance. This will prevent any radioactive dangers. A number of mercury, cyanide and arsenic waste repositories are operating worldwide including Canada and Germany and a number of radioactive waste storages are under construction with the Onkalo in Finland being the most advanced.

EnergySolutions, headquartered in Salt Lake City, Utah, is one of the largest processors of low level waste (LLW) in America, making it also one of the world's largest nuclear waste processors. It was formed in 2007 when Envirocare acquired three other nuclear waste disposal companies: Scientech D&D, BNG America, and Duratek.

The Savannah River National Laboratory (SRNL) is a multi-program national laboratory for the U.S. Department of Energy’s (DOE) Office of Environmental Management. SRNL is located at the Savannah River Site (SRS) near Jackson, South Carolina. It was founded in 1951, as the Savannah River Laboratory. It was certified as a national laboratory on May 7, 2004.

Bioremediation of radioactive waste or bioremediation of radionuclides is an application of bioremediation based on the use of biological agents bacteria, plants and fungi to catalyze chemical reactions that allow the decontamination of sites affected by radionuclides. These radioactive particles are by-products generated as a result of activities related to nuclear energy and constitute a pollution and a radiotoxicity problem due to its unstable nature of ionizing radiation emissions.

The Environmental Restoration Disposal Facility (ERDF) is a waste disposal facility located at the Hanford Nuclear Reservation in Richland, Washington, U.S.. Built in 1996, ERDF collects low-level waste, mixed waste, and other hazardous materials that are generated at Hanford. It does not collect any radioactive waste or other hazardous materials from other sites or the public. The hazardous waste dump was designed to be expanded as needed. The main storage facilities consist of single layer tanks that hold in all more than 17 million tons of nuclear waste. As of 2011, two new super tanks which hold double the amount of the single layer tanks were installed, providing safer levels of radioactivity in the surrounding ground areas and water sheds. Liners were previously installed to collect liquid released by the tanks or rain water that may seep in. The ERDF does not accept liquid waste, but water that seeps into the landfill is treated to keep the surrounding environment safe.

The Hanford Tank Waste Treatment and Immobilization Plant, known as the Vit Plant, will process the nuclear waste at the Hanford Site in Washington into a solid glass form using vitrification. A proven technology that has been used at the Savannah River Site and West Valley Demonstration Project, vitrification involves mixing the waste with glass-forming chemicals, heating it to 2,100 degrees Fahrenheit, and pouring it into stainless steel containers to solidify.

References

- Section 3116 Determination for Salt Waste Disposal at the Savannah River Site (February 28, 2005)

- Salt Waste Processing Facility Independent Technical Review (February 26, 2007)

- Independent Oversight Review of the Savannah River Site Salt Waste Processing Facility Safety Basis and Design Development (August 2013)

- Integrated Salt Waste Processing at the Savannah River Site, WM2015 Conference, March 15-19, 2015, Phoenix, Arizona USA (March 15, 2015)

- Salt Waste Processing Facility – Phase II – Aiken, SC (July 2017)

- Salt Waste Processing Facility Operations Underway (November 9, 2020)

- Savannah River’s Salt Waste Processing Facility begins full operations (January 25, 2021)