Mechanical advantage is a measure of the force amplification achieved by using a tool, mechanical device or machine system. The device preserves the input power and simply trades off forces against movement to obtain a desired amplification in the output force. The model for this is the law of the lever. Machine components designed to manage forces and movement in this way are called mechanisms. An ideal mechanism transmits power without adding to or subtracting from it. This means the ideal mechanism does not include a power source, is frictionless, and is constructed from rigid bodies that do not deflect or wear. The performance of a real system relative to this ideal is expressed in terms of efficiency factors that take into account departures from the ideal.

The crankset or chainset, is the component of a bicycle drivetrain that converts the reciprocating motion of the rider's legs into rotational motion used to drive the chain or belt, which in turn drives the rear wheel. It consists of one or more sprockets, also called chainrings or chainwheels attached to the cranks, arms, or crankarms to which the pedals attach. It is connected to the rider by the pedals, to the bicycle frame by the bottom bracket, and to the rear sprocket, cassette or freewheel via the chain.

In mechanical or automotive engineering, a freewheel or overrunning clutch is a device in a transmission that disengages the driveshaft from the driven shaft when the driven shaft rotates faster than the driveshaft. An overdrive is sometimes mistakenly called a freewheel, but is otherwise unrelated.

A sprocket or sprocket-wheel is a profiled wheel with teeth, or cogs, that mesh with a chain, track or other perforated or indented material. The name 'sprocket' applies generally to any wheel upon which radial projections engage a chain passing over it. It is distinguished from a gear in that sprockets are never meshed together directly, and differs from a pulley in that sprockets have teeth and pulleys are smooth.

Sturmey-Archer is a manufacturing company originally from Nottingham, England. It primarily produces bicycle hub gears, brakes and a great many other sundry bicycle components, most prominently during their heyday as a subsidiary of the Raleigh Bicycle Company. In the past, it also manufactured motorcycle hubs, gearboxes and engines.

Chain drive is a way of transmitting mechanical power from one place to another. It is often used to convey power to the wheels of a vehicle, particularly bicycles and motorcycles. It is also used in a wide variety of machines besides vehicles.

On a bicycle, the cogset or cluster is the set of multiple sprockets that attaches to the hub on the rear wheel. A cogset works with a rear derailleur to provide multiple gear ratios to the rider. Cogsets come in two varieties, freewheels or cassettes, of which cassettes are a newer development. Although cassettes and freewheels perform the same function and look almost the same when installed, they have important mechanical differences and are not interchangeable.

A toothed belt; timing belt; cogged belt; cog belt; or synchronous belt is a flexible belt with teeth moulded onto its inner surface. It is designed to run over matching toothed pulleys or sprockets. Toothed belts are used in a wide array of in mechanical devices, where high-power transmission is desired.

Bicycle gearing is the aspect of a bicycle drivetrain that determines the relation between the cadence, the rate at which the rider pedals, and the rate at which the drive wheel turns.

Hyperglide is the name given by cycling component manufacturer Shimano to a sprocket design in their bicycle derailleur tooth cassette systems. It varies gear tooth profiles, and/or pins along the faces of freewheel or cassette sprockets, or between the chainrings in a crankset, to ease shifting between them.

A belt-driven bicycle is a chainless bicycle that uses a toothed synchronous belt to transmit power from the pedals to the wheel. The belts are typically made by the same manufacturing companies that produce timing belts for automobiles, machinery, and other synchronous belt-drive applications.

Micro drive is a type of bicycle drivetrain, mostly BMX and MTB, that uses smaller than standard-sized sprockets. The smallest rear sprocket that fits on a freehub body is an 11-tooth, but with the use of a cassette hub, sometimes called a micro drive rear hub, sprockets as small as 8 teeth may be used.

A chain is a serial assembly of connected pieces, called links, typically made of metal, with an overall character similar to that of a rope in that it is flexible and curved in compression but linear, rigid, and load-bearing in tension. A chain may consist of two or more links. Chains can be classified by their design, which is dictated by their use:

An idler-wheel is wheel which serves only to transmit rotation from one shaft to another, in applications where it is undesirable to connect them directly. For example, connecting a motor to the platter of a phonograph, or the crankshaft-to-camshaft gear train of an automobile.

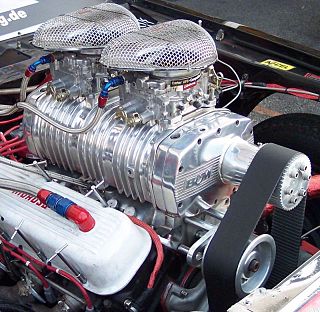

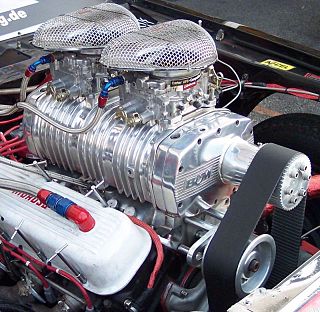

Motorcycle components and systems for a motorcycle are engineered, manufactured, and assembled in order to produce motorcycle models with the desired performance, aesthetics, and cost. The key components of modern motorcycles are presented below.

The saw chain, or "cutting chain", is a key component of a chainsaw. It consists of steel links held together by rivets, and superficially resembles the bicycle-style roller chain, although it is closer in design to a leaf chain. Its key differences are sharp cutting teeth on the outside of the chain loop, and flat drive links on the inside, to retain the chain on the saw's bar and allow propulsion by the engine or motor.

A master link or quick-release link is a roller chain accessory that allows convenient connection and disconnection of a chain without the need for a chain tool. It acts as a set of the chain's outer plates, so joining two sets of the chain's inner plate ends. Such master links may or may not be re-usable. A chain tool is nonetheless needed to adjust a chain's length, for example to shorten a new chain before connecting its ends. They are used on bicycles and motorcycles.