A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded.

A bellows or pair of bellows is a device constructed to furnish a strong blast of air. The simplest type consists of a flexible bag comprising a pair of rigid boards with handles joined by flexible leather sides enclosing an approximately airtight cavity which can be expanded and contracted by operating the handles, and fitted with a valve allowing air to fill the cavity when expanded, and with a tube through which the air is forced out in a stream when the cavity is compressed. It has many applications, in particular blowing on a fire to supply it with air.

Within industry, piping is a system of pipes used to convey fluids from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.

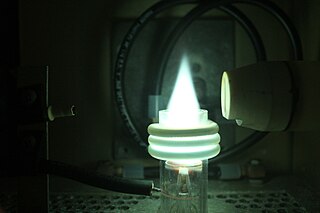

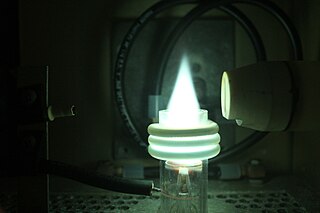

An inductively coupled plasma (ICP) or transformer coupled plasma (TCP) is a type of plasma source in which the energy is supplied by electric currents which are produced by electromagnetic induction, that is, by time-varying magnetic fields.

A slip joint is a mechanical construction allowing extension and compression in a linear structure.

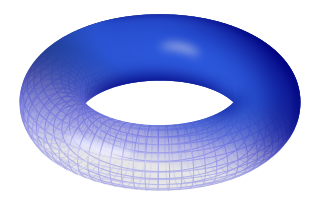

A bubble ring, or toroidal bubble, is an underwater vortex ring where an air bubble occupies the core of the vortex, forming a ring shape. The ring of air as well as the nearby water spins poloidally as it travels through the water, much like a flexible bracelet might spin when it is rolled on to a person's arm. The faster the bubble ring spins, the more stable it becomes. Bubble rings and smoke rings are both examples of vortex rings—the physics of which is still under active study in fluid dynamics. Devices have been invented which generate bubble vortex rings.

In photography, a lens hood or lens shade is a device used on the front end of a lens to block the Sun or other light source(s) to prevent glare and lens flare. Lens hoods may also be used to protect the lens from scratches and the elements without having to put on a lens cover.

The geometry of a lens hood is dependent on three things: the focal length of the lens, the size of the front lens element and the dimensions of the image sensor or film in the camera.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

An expansion joint or movement joint is an assembly designed to safely absorb the temperature-induced expansion and contraction of construction materials, to absorb vibration, to hold parts together, or to allow movement due to ground settlement or earthquakes. They are commonly found between sections of buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

Victaulic is a developer and producer of mechanical pipe joining systems and is the originator of the grooved pipe couplings joining system. Victaulic is a global company with 15 major manufacturing facilities, 28 branches, and over 3600 employees worldwide. Currently, Victaulic headquarters is located in Easton, PA. John F. Malloy has served as CEO since 2002.

A fitting is used in pipe systems to connect the straight pipe or tubing sections, adapt to different sizes or shapes and for other purposes, such as regulating fluid flow. "Plumbing" is generally used to describe the conveyance of water, gas, or liquid waste in domestic or commercial environments; "piping" is often used to describe the high-performance conveyance of fluids in specialized applications. "Tubing" is sometimes used for lighter-weight piping, especially that flexible enough to be supplied in coiled form.

Microflex Inc. is an international corporation manufacturing flexible metal products based in Ormond Beach, Florida and supplying a wide range of industries, with customers including NASA. It was founded in 1975 by Josif and Gjorgjija 'George' Atanasoski. It was originally located in New Haven, Connecticut, however it was relocated to Ormond Beach, Florida in 1980.

Ductile iron pipe is a pipe made of ductile cast iron commonly used for potable water transmission and distribution. This type of pipe is a direct development of earlier cast iron pipe, which it has superseded. The ductile iron used to manufacture the pipe is characterized by the spheroidal or nodular nature of the graphite within the iron. Typically, the pipe is manufactured using centrifugal casting in metal or resin lined moulds. Protective internal linings and external coatings are often applied to ductile iron pipes to inhibit corrosion: the standard internal lining is cement mortar and standard external coatings include bonded zinc, asphalt or water-based paint. In highly corrosive environments loose polyethylene sleeving (LPS) to encase the pipe may also be used. Life expectancy of unprotected ductile iron pipes depends on the corrosiveness of soil present and tends to be shorter where soil is highly corrosive. However, a lifespan in excess of 100 years has been estimated for ductile iron pipelines installed using "evolved laying practices", including use of properly installed LPS. Studies of ductile iron pipe's environmental impact have differing findings regarding emissions and energy consumed. Ductile iron pipe manufactured in the United States has been certified as a sustainable product by the Institute for Market Transformation to Sustainability.

US Bellows is a manufacturer of metal bellows, fabric expansion joints, and metallic expansion joints including refractory lined, hinged, gimbal, slip-type, in-line pressure balanced, and elbow pressure balanced expansion joints. It was acquired by Piping Technology and Products in 1997 from Ketema-U.S. Bellows, Inc. and is now located in Houston, Texas. U.S. Bellows, Inc. provides a variety of expansion joints for piping and duct systems and has been a member of the Expansion Joint Manufacturers Association, Inc. since 2002. In December 2011, U.S. Bellows acquired all bellows assets of the former Lortz Manufacturing companies, doubling its manufacturing capabilities. It is a privately held company owned by Durga D. Agrawal. It is a subsidiary of Piping Technology and Products. These companies provide pipe supports and expansion joints to international companies including Dow Chemical Company, Chevron Corporation, ExxonMobil, and Bechtel.

Piping Technology and Products is a privately owned pipe support manufacturing and engineering company headquartered in Houston, Texas, United States. Its wholly owned subsidiaries are US Bellows, Sweco Fab, Fronek Anchor/Darling Enterprise, and Pipe Shields. These companies provide pipe supports, expansion joints, shock and vibration controls, and pre-insulated supports to a variety of industries including LNG, chemical, petrochemical, pulp & paper, and aerospace.

A Refractory lined expansion joint is an assembly used in a pipe line to allow it to expand and contract as climate conditions move from hot to cold and helps to ensure that the system remains functional. The refractory-lining can be vibra cast insulation with anchors, abrasion resistant refractory in hex mesh, gunned insulating refractory, or poured insulating refractory. Refractory lined expansion joints can be hinged, in-line pressure balanced, gimbal, tied-universal depending on the temperature, pressure, movement and flow media conditions.

A hinged expansion joint is a metallic assembly, that can rotate in a single plane, used to absorb changes resulting from piping thermal expansion or contraction.

Metal expansion joints are compensating elements for thermal expansion and relative movement in pipelines, containers and machines. They consist of one or more metal bellows, connectors at both ends, and tie rods that depend on the application. They are differentiated according to the three basic types of movement: axial, angular and lateral expansion joints. Expansion joints have usage in various sectors, like energy productions, paper industry, chemical industry, water treatment, oil and gas. Everywhere where exist pipelines and occurs thermal movements or vibration, then expansion joints can be used.