In physics, cryogenics is the production and behaviour of materials at very low temperatures.

Distillation is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation. Distillation may result in essentially complete separation, or it may be a partial separation that increases the concentration of selected components in the mixture. In either case, the process exploits differences in the relative volatility of the mixture's components. In industrial applications, distillation is a unit operation of practically universal importance, but it is a physical separation process, not a chemical reaction.

Liquid hydrogen (LH2 or LH2) is the liquid state of the element hydrogen. Hydrogen is found naturally in the molecular H2 form.

The following is a timeline of low-temperature technology and cryogenic technology .. It also lists important milestones in thermometry, thermodynamics, statistical physics and calorimetry, that were crucial in development of low temperature systems.

A vacuum flask is an insulating storage vessel that greatly lengthens the time over which its contents remain hotter or cooler than the flask's surroundings. Invented by Sir James Dewar in 1892, the vacuum flask consists of two flasks, placed one within the other and joined at the neck. The gap between the two flasks is partially evacuated of air, creating a near-vacuum which significantly reduces heat transfer by conduction or convection.

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species, either cold or hot, to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system.

Liquid nitrogen—LN2—is nitrogen in a liquid state at low temperature (−195.79 °C (77 K; −320 °F) boiling point at sea level). It is produced industrially by fractional distillation of liquid air. It is a colorless, low viscosity liquid that is widely used as a coolant.

A boiling liquid expanding vapor explosion is an explosion caused by the rupture of a vessel containing a pressurized liquid that has reached temperatures above its boiling point. Because the boiling point of a liquid rises with pressure, the contents of the pressurized vessel can remain liquid so long as the vessel is intact. If the vessel's integrity is compromised, the loss of pressure and dropping boiling point can cause the liquid to rapidly convert to gas and expand extremely rapidly. If the gas is combustible as well, as is the case e.g. with hydrocarbons and alcohols, further damage can be caused by an ensuing fire.

Bottled gas is a term used for substances which are gaseous at standard temperature and pressure (STP) and have been compressed and stored in carbon steel, stainless steel, aluminum, or composite bottles known as gas cylinders.

A vacuum insulated panel (VIP) is a form of thermal insulation consisting of a gas-tight enclosure surrounding a rigid core, from which the air has been evacuated. It is used in building construction, refrigeration units, and insulated shipping containers to provide better insulation performance than conventional insulation materials.

Pressure swing adsorption (PSA) is a technology used to separate some gas species from a mixture of gases under pressure according to the species' molecular characteristics and affinity for an adsorbent material. It operates at near-ambient temperatures and differs significantly from cryogenic distillation techniques of gas separation. Specific adsorbent materials are used as a trap, preferentially adsorbing the target gas species at high pressure. The process then swings to low pressure to desorb the adsorbed material.

A deaerator is a device that removes oxygen and other dissolved gases from liquids and pumpable compounds.

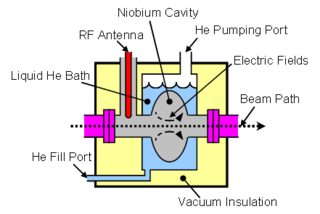

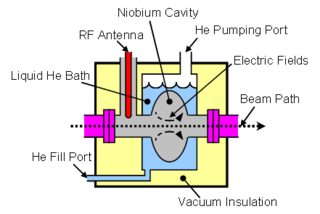

A cryomodule is a section of a modern particle accelerator composed of superconducting RF (SRF) acceleration cavities, and needs very low operating temperatures. The cryomodule is a complex, state-of-the-art supercooled component in which particle beams are accelerated for scientific research. The niobium cavities are cooled with liquid helium.

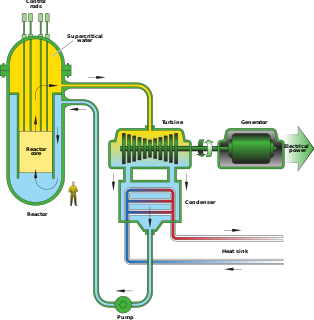

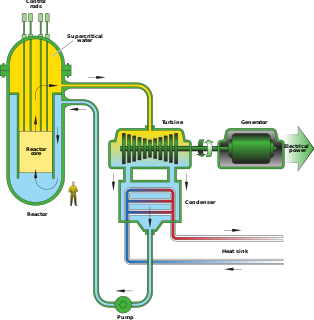

The supercritical water reactor (SCWR) is a concept Generation IV reactor, mostly designed as light water reactor (LWR) that operates at supercritical pressure. The term critical in this context refers to the critical point of water, and must not be confused with the concept of criticality of the nuclear reactor.

A vacuum coffee maker brews coffee using two chambers where vapor pressure and gravity produce coffee. This type of coffee maker is also known as vac pot, siphon or syphon coffee maker, and was invented by Loeff of Berlin in the 1830s. These devices have since been used for more than a century in many parts of the world. Design and composition of the vacuum coffee maker varies. The chamber material is borosilicate glass, metal, or plastic, and the filter can be either a glass rod or a screen made of metal, cloth, paper, or nylon. The Napier Vacuum Machine, presented in 1840, was an early example of this technique. While vacuum coffee makers generally were excessively complex for everyday use, they were prized for producing a clear brew, and were quite popular until the middle of the twentieth century. Vacuum coffee makers remain popular in some parts of Asia, including Japan and Taiwan. The Bauhaus interpretation of this device can be seen in Gerhard Marcks' Sintrax coffee maker of 1925.

Dissolved gas analysis (DGA) is the study of dissolved gases in transformer oil.

Industrial autoclaves are pressure vessels used to process parts and materials which require exposure to elevated pressure and temperature. The manufacture of high-performance components from advanced composites often requires autoclave processing.

A liquid nitrogen vehicle is powered by liquid nitrogen, which is stored in a tank. Traditional nitrogen engine designs work by heating the liquid nitrogen in a heat exchanger, extracting heat from the ambient air and using the resulting pressurized gas to operate a piston or rotary motor. Vehicles propelled by liquid nitrogen have been demonstrated, but are not used commercially. One such vehicle, Liquid Air was demonstrated in 1902.

A cryogenic storage dewar is a specialised type of vacuum flask used for storing cryogens, whose boiling points are much lower than room temperature. Cryogenic storage dewars may take several different forms including open buckets, flasks with loose-fitting stoppers and self-pressurising tanks. All dewars have walls constructed from two or more layers, with a high vacuum maintained between the layers. This provides very good thermal insulation between the interior and exterior of the dewar, which reduces the rate at which the contents boil away. Precautions are taken in the design of dewars to safely manage the gas which is released as the liquid slowly boils. The simplest dewars allow the gas to escape either through an open top or past a loose-fitting stopper to prevent the risk of explosion. More sophisticated dewars trap the gas above the liquid, and hold it at high pressure. This increases the boiling point of the liquid, allowing it to be stored for extended periods. Excessive vapour pressure is released automatically through safety valves. The method of decanting liquid from a dewar depends upon its design. Simple dewars may be tilted, to pour liquid from the neck. Self-pressurising designs use the gas pressure in the top of the dewar to force the liquid upward through a pipe leading to the neck.

Ultra-high-purity steam, also called clean steam, UHP steam or high purity water vapor, is used in a variety of industrial manufacturing processes that require oxidation or annealing. These processes include the growth of oxide layers on silicon wafers for the semiconductor industry, originally described by the Deal-Grove model, and for the formation of passivation layers used to improve the light capture ability of crystalline photovoltaic cells. Several methods and technologies can be employed to generate ultra high purity steam, including pyrolysis, bubbling, direct liquid injection and purified steam generation. The level of purity, or the relative lack of contamination, affects the quality of the oxide layer or annealed surface. The method of delivery affects growth rate, uniformity and electrical performance. Oxidation and annealing are common steps in the manufacture of such devices as microelectronics and solar cells.