A loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

Warp, warped or warping may refer to:

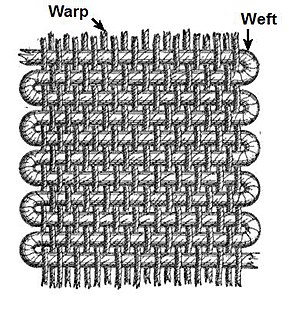

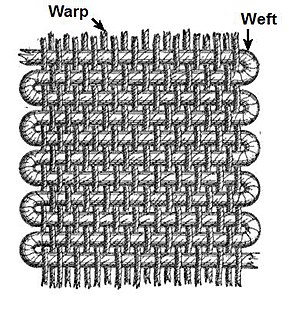

Warp and weft are the two basic components used in weaving to turn thread or yarn into fabric. The lengthwise or longitudinal warp yarns are held stationary in tension on a frame or loom while the transverse weft is drawn through and inserted over and under the warp. A single thread of the weft crossing the warp is called a pick. Terms vary. Each individual warp thread in a fabric is called a warp end or end.

Textile manufacturing is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Overall, many things can be made with cotton, not just clothing.

For woven textiles, grain refers to the orientation of the weft and warp threads. The three named grains are straight grain, cross grain, and the bias grain. In sewing, a pattern piece can be cut from fabric in any orientation, and the chosen grain or orientation will affect the way the fabric hangs and stretches and thus the fit of a garment. Generally speaking a piece is said to be cut on a particular grain when the longest part of the pattern or the main seams of the finished piece are aligned with that grain. Non-woven materials such as felt, interfacing or leather do not have a grain.

Terrycloth, terry cloth, terry cotton, terry toweling, terry, terry towel, or simply toweling is a fabric woven with many protruding loops of thread which can absorb large amounts of water. It can be manufactured by weaving or knitting. Terrycloth is woven on special looms that have two beams of longitudinal warp through which the filler or weft is fired laterally. The first industrial production of terrycloth towels was initiated by the English manufacturer Christy in 1850. According to the Oxford English Dictionary, the word may derive from French tiré 'drawn', past participle of tirer 'draw out'.

Kasuri (絣) is the Japanese term for fabric that has been woven with fibers dyed specifically to create patterns and images in the fabric, typically referring to fabrics produced within Japan using this technique. It is a form of ikat dyeing, traditionally resulting in patterns characterized by their blurred or brushed appearance.

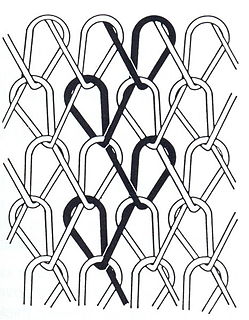

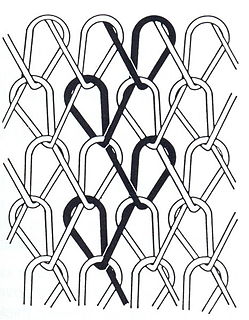

Warp knitting is a family of knitting methods in which the yarn zigzags along the length of the fabric; i.e., following adjacent columns, or wales, of knitting, rather than a single row, or course. For comparison, knitting across the width of the fabric is called weft knitting.

Knitted fabric is a textile that results from knitting, the process of inter-looping of yarns or inter-meshing of loops. Its properties are distinct from woven fabric in that it is more flexible and can be more readily constructed into smaller pieces, making it ideal for socks and hats.

A selvage or selvedge is a "self-finished" edge of a piece of fabric which keeps it from unraveling and fraying. The term "self-finished" means that the edge does not require additional finishing work, such as hem or bias tape, to prevent fraying.

In the context of materials, stuff can refer to any manufactured material. This is illustrated from a quote by Sir Francis Bacon in his 1658 publication New Atlantis: "Wee have also diverse Mechanicall Arts, which you have not; And Stuffes made by them; As Papers, Linnen, Silks, Tissues; dainty Works of Feathers of wonderfull Lustre; excellent Dies, and many others." In Coventry, those completing seven-year apprenticeships with stuff merchants were entitled to become freemen of the city.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Fully fashioned knitting machines are those warp knitting knitting machines which can shape a fabric by adding and reducing stitches. This method of shaping improves the fit of an article.

A knotted-pile carpet is a carpet containing raised surfaces, or piles, from the cut off ends of knots woven between the warp and weft. The Ghiordes/Turkish knot and the Senneh/Persian knot, typical of Anatolian carpets and Persian carpets, are the two primary knots. A flat or tapestry woven carpet, without pile, is a kilim. A pile carpet is influenced by width and number of warp and weft, pile height, knots used, and knot density.

Ottoman is a widthways-ribbed textile with pronounced, raised 'ribs' along its weft. Similar to grosgrain, Ottoman is known as a corded fabric, using a thicker yarn in the weft rather than the warp to create raised stripes running across the width of the fabric.

Yarn weight refers to the thickness of yarn used by knitters, weavers, crocheters and other fiber artists.

Textile manufacturing is one of the oldest human activities. The oldest known textiles date back to about 5000 B.C. In order to make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving to create cloth. The machine used for weaving is the loom. Cloth is finished by what are described as wet process to become fabric. The fabric may be dyed, printed or decorated by embroidering with coloured yarns.

Waffle fabric, also known as honeycomb fabric, has raised threads that form small rectangles. It can be made by either weaving or knitting. Waffle weave is a further exploitation of plain weave and twill weave which produces a three-dimensional effect. The combination of warp and weft floats creates the structure. It is woven partly on tabby areas surrounded by ridges of long floats. The weave consists of warp and weft floats arranged around a plain weave center. The warp and weft threads are interlaced and floating in a way that creates small square ridges and hollows in the fabric in a regular pattern.

Malimo is a textile manufacturing technique in which warp and weft yarns are sewn together. The method is also referred to as "stitch-bonding." It was invented in Eastern Germany in the 1950s. Malimo is used in a variety of applications, including apparel fabrics, wind turbine wings and isolation fabrics, and aerospace.

Warp and weft are the components of weaving to turn thread into cloth.