An oil well is a boring in the Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released along with the oil. A well that is designed to produce only gas may be termed a gas well.

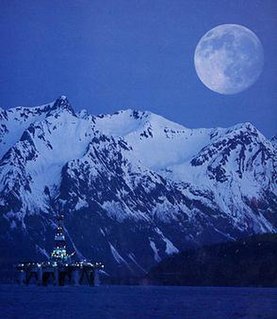

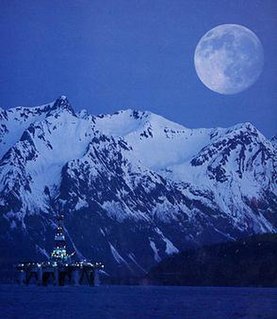

Ocean Ranger was a semi-submersible mobile offshore drilling unit that sank in Canadian waters on 15 February 1982. It was drilling an exploration well on the Grand Banks of Newfoundland, 267 kilometres (166 mi) east of St. John's, Newfoundland, for Mobil Oil of Canada, Ltd. (MOCAN) with 84 crew members on board when it sank. There were no survivors.

A blowout is the uncontrolled release of crude oil and/or natural gas from an oil well or gas well after pressure control systems have failed. Modern wells have blowout preventers intended to prevent such an occurrence. An accidental spark during a blowout can lead to a catastrophic oil or gas fire.

A blowout preventer (BOP) is a large, specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil and/or natural gas from a well. They are usually installed in stacks of other valves.

Seaboard International is a privately held manufacturer of highly engineered oil and gas pressure control equipment providing services for worldwide onshore and offshore oil & gas exploration, drilling and production operations. Seaboard began development of wellhead and electric feed-thru connector product lines in 1974 and is headquartered in Houston, Texas, United States.

The extraction of petroleum is the process by which usable petroleum is drawn out from beneath the earth's surface location

A well intervention, or well work, is any operation carried out on an oil or gas well during, or at the end of, its productive life that alters the state of the well or well geometry, provides well diagnostics, or manages the production of the well.

Subsea is fully submerged ocean equipment, operations or applications, especially when some distance offshore, in deep ocean waters, or on the seabed. The term is frequently used in connection with oceanography, marine or ocean engineering, ocean exploration, remotely operated vehicle (ROVs) autonomous underwater vehicles (AUVs), submarine communications or power cables, seafloor mineral mining, oil and gas, and offshore wind power.

The two barrier rule is a policy of safety for work on piping carrying high pressure and/or high temperature fluids. It is commonly used by oil companies. The rule simply states that for any work that must be done on a section of piping, which involves breaking containment, there must be at least two barriers separating the fluids from the broken area. The purpose behind specifying two barriers is to ensure redundancy. The risk of a total loss of containment is reduced if there are two independent isolations as it is highly improbable they would both fail at the same time.

A downhole safety valve refers to a component on an oil and gas well, which acts as a failsafe to prevent the uncontrolled release of reservoir fluids in the event of a worst-case-scenario surface disaster. It is almost always installed as a vital component on the completion.

The Andrew oilfield is a relatively small hydrocarbon field in the UK sector of the North Sea, 230 kilometres (140 mi) North-East of Aberdeen and it is operated by BP. It is produced from a single platform, which is also the hub of the Kinnoull, Cyrus and Farragon subsea developments.

Well integrity, in regard to oil wells, is defined by NORSOK D-010 as the "“Application of technical, operational and organizational solutions to reduce risk of uncontrolled release of formation fluids throughout the life cycle of a well”. There are various facets to well integrity, including accountability/responsibility, well operating processes, well service processes, tubing/annulus integrity, tree/wellhead integrity and testing of safety systems.

Well completion is the process of making a well ready for production. This principally involves preparing the bottom of the hole to the required specifications, running in the production tubing and its associated down hole tools as well as perforating and stimulating as required. Sometimes, the process of running in and cementing the casing is also included. After a well has been drilled, should the drilling fluids be removed, the well would eventually close in upon itself. Casing ensures that this will not happen while also protecting the wellstream from outside incumbents, like water or sand.

The Douglas Complex is a 54-metre (177 ft) high system of three linked platforms in the Irish Sea, 24 kilometres (15 mi) off the North Wales coast. The Douglas oil field was discovered in 1990, and production commenced in 1996. Now operated by Eni, the complex consists of the wellhead platform, which drills into the seabed, a processing platform, which separates oil, gas and water, and thirdly an accommodation platform, which is composed of living quarters for the crew. This accommodation module was formerly the Morecambe Flame jack-up drilling rig.

In oil drilling, a casing head is a simple metal flange welded or screwed onto the top of the conductor pipe or the casing and forms part of the wellhead system for the well.

Cameron International Corporation is a Schlumberger company and a global provider of pressure control, processing, flow control and compression systems as well as project management and aftermarket services for the oil and gas and process industries. It employs approximately 23,000 people and is headquartered in Park Towers South, Houston, Texas. In 2006 Cooper Cameron was officially renamed "Cameron."

Subsea Production Systems are typical wells located on the seabed, shallow or deep water. Generally termed as Floating production system, where the petroleum is extracted at the seabed and the same can be tied back to an already existing production platform or an onshore facility. The oil platform well is drilled by a movable rig and the extracted oil or natural gas is transported by submarine pipeline under the sea and then to rise to a processing facility.

It is classified into