Rebar, known when massed as reinforcing steel or reinforcement steel, is a steel bar or mesh of steel wires used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has weak tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface is often deformed to promote a better bond with the concrete.

A fastener or fastening is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints; that is, joints that can be removed or dismantled without damaging the joining components. Welding is an example of creating permanent joints. Steel fasteners are usually made of stainless steel, carbon steel, or alloy steel.

A washer is a thin plate with a hole that is normally used to distribute the load of a threaded fastener, such as a bolt or nut. Other uses are as a spacer, spring, wear pad, preload indicating device, locking device, and to reduce vibration. Washers often have an outer diameter (OD) about twice their inner diameter (ID), but this can vary quite widely.

Bolted joints are one of the most common elements in construction and machine design. They consist of fasteners that capture and join other parts, and are secured with the mating of screw threads.

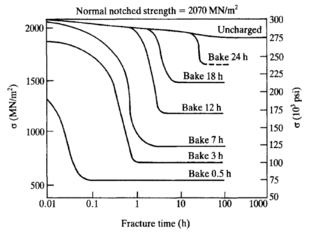

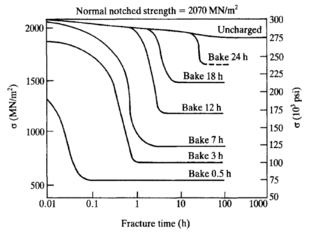

Hydrogen embrittlement (HE) also known as hydrogen assisted cracking (HAC) and hydrogen-induced cracking (HIC), describes the embrittling of metal after being exposed to hydrogen. It is a complex process that is not completely understood because of the variety of mechanisms that can lead to embrittlement. Mechanisms that have been proposed to explain embrittlement include the formation of brittle hydrides within certain metals, the creation of voids that can lead to bubbles and pressure build-up within a material and enhanced decohesion or localised plasticity that assist in the propagation of cracks.

Anchor bolts are used to connect structural and non-structural elements to the concrete. The connection is made by an assembling of different components such as: anchor bolts, steel plates, stiffeners. Anchor bolts transfer different types of load: tension forces and shear forces. A connection between structural elements can be represented by steel column attached to reinforced concrete foundation. Whereas, a common case of non-structural element attached to a structural one is represented by the connection between a facade system and a reinforced concrete wall.

A screw is a type of fastener, in some ways similar to a bolt, typically made of metal, and characterized by a helical ridge, known as a male thread. Screws are used to fasten materials by digging in and wedging into a material when turned, while the thread cuts grooves in the fastened material that may help pull fastened materials together and prevent pull-out. There are many screws for a variety of materials; those commonly fastened by screws include wood, sheet metal, and plastic.

ASTM A992 steel is a structural steel alloy often used in the USA for steel wide-flange and I beams. Like other carbon steels, the density of ASTM A992 steel is approximately 7850 kg/m3. ASTM A992 steel has the following minimum mechanical properties, according to ASTM specification A992/A992M. Tensile yield strength, 345 MPa (50 ksi); tensile ultimate strength, 450 MPa (65 ksi); strain to rupture in a 200-mm-long test specimen, 18%; strain to rupture in a 50-mm-long test specimen, 21%.

ISO 898 is an international standard that defines mechanical and physical properties for metric fasteners. This standard is the origin for other standards that define properties for similar metric fasteners, such as SAE J1199 and ASTM F568M. It is divided into five (nonconsecutive) parts:

Direct tension indicators, or DTIs, are single use mechanical load cells used to indicate when the required tension has been achieved in structural fastener assemblies.

A square nut is a four-sided nut. Compared to standard hex nuts, square nuts have a greater surface in contact with the part being fastened, and therefore provide greater resistance to loosening. They are also much less likely to become rounded-off after repeated loosening/tightening cycles. Square nuts are typically mated with square-headed bolts. Square nuts are used along with flat washers in order to avoid damage from its sharp edges and helps to increase the strength of the fastener. Square nuts can have standard, fine or coarse threading with platings of zinc yellow, plain, zinc clear, tin and cadmium, among others. Most can meet either the ASTM A194, ASTM A563, or ASTM F594 standard.

ASME is a non-profit organization that continues to develop and maintains nearly 600 codes and standards in a wide range of disciplines. Some of which includes the Boiler and Pressure Vessel Code (BPVC), Elevators and Escalators, Piping and Pipelines, Bioprocessing Equipment (BPE), Nuclear Facility Applications (NQA), Process Performance Test Codes (PTC), and Valves, Flanges, Fittings and Gaskets (B16).

ASTM A193/A193M is a specification from the ASTM International that primarily govern industrial piping applications. In the assembly of an industrial plant, many complex components are bolted together of which include parts such as valves, piping, and pressure vessels. ASTM A193 defines the methodology to procure and certify externally threaded fasteners according to specific chemical and mechanical criteria. It is standards such as this that allow industrial process applications to be safely engineered so they do not exceed the tensile strength of the fasteners that hold them together.

Adhesive bonding is a process by which two members of equal or dissimilar composition are joined. It is used in place of, or to complement other joining methods such mechanical fasting by the use nails, rivets, screws or bolts and many welding processes. The use of adhesives provides many advantages over welding and mechanical fastening in steel construction; however, many challenges still exist that have made the use of adhesives in structural steel components very limited.

The Research Council on Structural Connections (RCSC) is a research organization focused on bolted structural connections. Their technical standard on this subject is cited in the US steel design code.