A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

A furnace, referred to as a heater or boiler in British English, is an appliance used to generate heat for all or part of a building. Furnaces are mostly used as a major component of a central heating system. Furnaces are permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water. Heating appliances that use steam or hot water as the fluid are normally referred to as a residential steam boilers or residential hot water boilers. The most common fuel source for modern furnaces in North America and much of Europe is natural gas; other common fuel sources include LPG, fuel oil, wood and in rare cases coal. In some areas electrical resistance heating is used, especially where the cost of electricity is low or the primary purpose is for air conditioning. Modern high-efficiency furnaces can be up to 98% efficient and operate without a chimney, with a typical gas furnace being about 80% efficient. Waste gas and heat are mechanically ventilated through either metal flue pipes or polyvinyl chloride (PVC) pipes that can be vented through the side or roof of the structure. Fuel efficiency in a gas furnace is measured in AFUE.

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated to steam have many uses.

A stove or range is a device that burns fuel or uses electricity to generate heat inside or on top of the apparatus, to be used for general warming or cooking. It has evolved highly over time, with cast-iron and induction versions being developed. Stoves can be powered with many fuels, such as electricity, gasoline, wood, and coal.

Wood fuel is a fuel such as firewood, charcoal, chips, sheets, pellets, and sawdust. The particular form used depends upon factors such as source, quantity, quality and application. In many areas, wood is the most easily available form of fuel, requiring no tools in the case of picking up dead wood, or few tools, although as in any industry, specialized tools, such as skidders and hydraulic wood splitters, have been developed to mechanize production. Sawmill waste and construction industry by-products also include various forms of lumber tailings.

A central heating system provides warmth to a number of spaces within a building from one main source of heat. It is a component of heating, ventilation, and air conditioning systems, which can both cool and warm interior spaces.

A fireplace or hearth is a structure made of brick, stone or metal designed to contain a fire. Fireplaces are used for the relaxing ambiance they create and for heating a room. Modern fireplaces vary in heat efficiency, depending on the design.

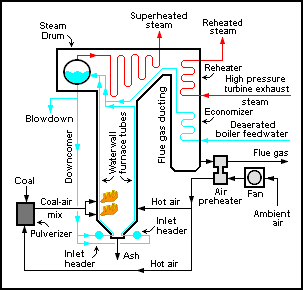

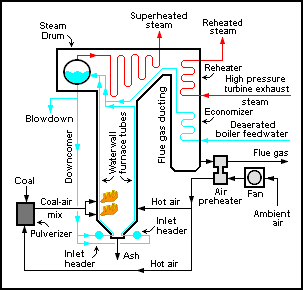

An air preheater is any device designed to heat air before another process (for example, combustion in a boiler With the primary objective of increasing the thermal efficiency of the process. They may be used alone or to replace a recuperative heat system or to replace a steam coil.

A flue is a duct, pipe, or opening in a chimney for conveying exhaust gases from a fireplace, furnace, water heater, boiler, or generator to the outdoors. Historically the term flue meant the chimney itself. In the United States, they are also known as vents for boilers and as breeching for water heaters and modern furnaces. They usually operate by buoyancy, also known as the stack effect, or the combustion products may be 'induced' via a blower. As combustion products contain carbon monoxide and other dangerous compounds, proper 'draft', and admission of replacement air is imperative. Building codes, and other standards, regulate their materials, design, and installation.

A masonry heater is a device for warming an interior space through radiant heating, by capturing the heat from periodic burning of fuel, and then radiating the heat at a fairly constant temperature for a long period. Masonry heaters covered in tile are called cocklestoves. The technology has existed in different forms, from back into the Neoglacial and Neolithic periods. Archaeological digs have revealed excavations of ancient inhabitants utilizing hot smoke from fires in their subterranean dwellings, to radiate into the living spaces. These early forms have evolved into modern systems.

A kerosene heater, also known as a paraffin heater, is typically a portable, unvented, kerosene-fueled, space heating device. In Japan and other countries, they are a primary source of home heat. In the United States and Australia, they are a supplemental heat or a source of emergency heat during a power outage. Most kerosene heaters produce between 3.3 and 6.8 kilowatts.

Renewable heat is an application of renewable energy referring to the generation of heat from renewable sources; for example, feeding radiators with water warmed by focused solar radiation rather than by a fossil fuel boiler. Renewable heat technologies include renewable biofuels, solar heating, geothermal heating, heat pumps and heat exchangers. Insulation is almost always an important factor in how renewable heating is implemented.

A pulverized coal-fired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal that is blown into the firebox.

A cold water flat is an apartment that has no running hot water.

Furo, or the more common and polite form ofuro, is a Japanese bath and/or bathroom. Specifically it is a type of bath which originated as a short, steep-sided wooden bathtub. Baths of this type are found all over Japan in houses, apartments and traditional Japanese inns (ryokan) but are now usually made out of a plastic or stainless steel.

A wood-burning stove is a heating or cooking appliance capable of burning wood fuel, often called solid fuel, and wood-derived biomass fuel, such as sawdust bricks. Generally the appliance consists of a solid metal closed firebox, often lined by fire brick, and one or more air controls. The first wood-burning stove was patented in Strasbourg in 1557. This was two centuries before the Industrial Revolution, so iron was still prohibitively expensive. The first wood-burning stoves were high-end consumer items and only gradually became used widely.

The outdoor wood boiler is a variant of the classic wood stove adapted for set-up outdoors while still transferring the heat to interior buildings.

A hot water storage tank is a water tank used for storing hot water for space heating or domestic use.

An industrial furnace, also known as a direct heater or a direct fired heater, is a device used to provide heat for an industrial process, typically higher than 400 degrees Celsius. They are used to provide heat for a process or can serve as reactor which provides heats of reaction. Furnace designs vary as to its function, heating duty, type of fuel and method of introducing combustion air. Heat is generated by an industrial furnace by mixing fuel with air or oxygen, or from electrical energy. The residual heat will exit the furnace as flue gas. These are designed as per international codes and standards the most common of which are ISO 13705 / American Petroleum Institute (API) Standard 560. Types of industrial furnaces include batch ovens, metallurgical furnaces, vacuum furnaces, and solar furnaces. Industrial furnaces are used in applications such as chemical reactions, cremation, oil refining, and glasswork.