Pressure measurement is the measurement of an applied force by a fluid on a surface. Pressure is typically measured in units of force per unit of surface area. Many techniques have been developed for the measurement of pressure and vacuum. Instruments used to measure and display pressure mechanically are called pressure gauges,vacuum gauges or compound gauges. The widely used Bourdon gauge is a mechanical device, which both measures and indicates and is probably the best known type of gauge.

A pump is a device that moves fluids, or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy.

Pneumatics is the use of gas or pressurized air in mechanical systems.

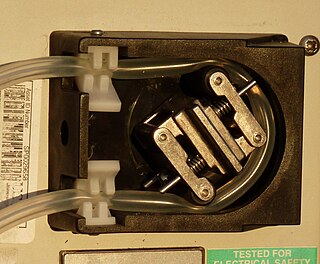

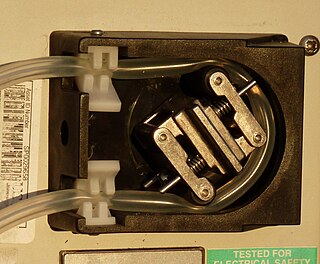

A peristaltic pump, also commonly known as a roller pump, is a type of positive displacement pump used for pumping a variety of fluids. The fluid is contained in a flexible tube fitted inside a circular pump casing. Most peristaltic pumps work through rotary motion, though linear peristaltic pumps have also been made. The rotor has a number of "wipers" or "rollers" attached to its external circumference, which compress the flexible tube as they rotate by. The part of the tube under compression is closed, forcing the fluid to move through the tube. Additionally, as the tube opens to its natural state after the rollers pass, more fluid is drawn into the tube. This process is called peristalsis and is used in many biological systems such as the gastrointestinal tract. Typically, there will be two or more rollers compressing the tube, trapping a body of fluid between them. The body of fluid is transported through the tube, toward the pump outlet. Peristaltic pumps may run continuously, or they may be indexed through partial revolutions to deliver smaller amounts of fluid.

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly.

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid to flow through it in only one direction.

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, forming a seal at the interface.

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates.

EPDM rubber is a type of synthetic rubber that is used in many applications.

A solenoid valve is an electromechanically operated valve.

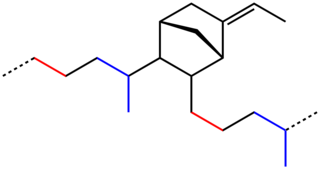

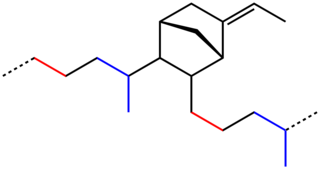

Metal rubber is a broad, informal name for several conductive plastic polymers with metal ions produced by NanoSonic Inc. in cooperation with Virginia Tech. This self-assembling nanocomposite is flexible and durable to high and low pressures, temperatures, tensions, and most chemical reactions, and retains all of its physical and chemical properties upon being returned to a ground state. NanoSonic’s Metal rubber™ is an electrically conductive and flexible elastomer. It can be mechanically strained to greater than 1000% of its original dimensions while remaining electrically conductive. As Metal rubber can carry data and electrical power and is environmentally rugged, it can be used as a flexible and stretchable electrical conductor in the aerospace/defense, electronics, and bioengineering markets.

Pneumatic tires are manufactured according to relatively standardized processes and machinery, in around 455 tire factories in the world. With over 1 billion tires manufactured worldwide annually, the tire industry is a major consumer of natural rubber. Tire factories start with bulk raw materials such as synthetic rubber, carbon black, and chemicals and produce numerous specialized components that are assembled and cured.

Level sensors detect the level of liquids and other fluids and fluidized solids, including slurries, granular materials, and powders that exhibit an upper free surface. Substances that flow become essentially horizontal in their containers because of gravity whereas most bulk solids pile at an angle of repose to a peak. The substance to be measured can be inside a container or can be in its natural form. The level measurement can be either continuous or point values. Continuous level sensors measure level within a specified range and determine the exact amount of substance in a certain place, while point-level sensors only indicate whether the substance is above or below the sensing point. Generally the latter detect levels that are excessively high or low.

FKM is a family of fluorocarbon-based fluoroelastomer materials defined by ASTM International standard D1418, and ISO standard 1629. It is commonly called fluorine rubber or fluoro-rubber. FKM is an abbreviation of Fluorine Kautschuk Material. All FKMs contain vinylidene fluoride as the common monomer, to which different other monomers are added for specific types and functionalities, fitting the desired application.

A expansion joint, or movement joint, is an assembly designed to hold parts together while safely absorbing temperature-induced expansion and contraction of building materials. They are commonly found between sections of buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

Diaphragm valves consists of a valve body with two or more ports, a flexible diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve body may be constructed from plastic, metal or other materials depending on the intended use.

Metal bellows are elastic vessels that can be compressed when pressure is applied to the outside of the vessel, or extended under vacuum. When the pressure or vacuum is released, the bellows will return to its original shape, provided the material has not been stressed past its yield strength. They are used both for their ability to deform under pressure and to provide a hermetic seal that allows movement.

Forensic materials engineering, a branch of forensic engineering, focuses on the material evidence from crime or accident scenes, seeking defects in those materials which might explain why an accident occurred, or the source of a specific material to identify a criminal. Many analytical methods used for material identification may be used in investigations, the exact set being determined by the nature of the material in question, be it metal, glass, ceramic, polymer or composite. An important aspect is the analysis of trace evidence such as skid marks on exposed surfaces, where contact between dissimilar materials leaves material traces of one left on the other. Provided the traces can be analysed successfully, then an accident or crime can often be reconstructed. Another aim will be to determine the cause of a broken component using the technique of fractography.

Cracks can be formed in many different elastomers by ozone attack, and the characteristic form of attack of vulnerable rubbers is known as ozone cracking. The problem was formerly very common, especially in tires, but is now rarely seen in those products owing to preventive measures.