Causes

Annealing Errors

During the annealing process of die making, two main errors can occur, resulting in less than perfect dies. It is impossible to tell without expensive and lengthy tests whether these errors occurred, but they will lead to significantly weaker dies and a higher tendency to deteriorate quickly. The first thing which can happen to a die in this process what metallurgists call decarburization. Decarburization is the result of an improper mix of metals and chemicals in the annealing furnace where the dies are sent to soften. If there is not enough ambient carbon in the furnace, the steel will give up some of its carbon and will become soft. The result is a thin surface of inadequate metal whose chemical composition has been altered and is below standard.

Another less obvious error can also occur when heating the dies. After being taken out of the annealing furnace, the dies must cool for 24 to 36 hours. They are usually given an oil bath to cool them more quickly, but the dies must still cool for a period of several hours. When the dies are cooling, if they are not stored properly or not allowed to fully cool before being used, the result is a much softer die. When the die is subjected to the hubbing press again and work hardened again, it will be softer and more susceptible to wear. If the die is softer because it was not fully cooled, it will not harden to the same standard as a die which has received proper treatment. However, there will not be a noticeable difference between a good die and a bad die; the change in the structure of the die is not apparent until it is used for a period of time.

Overuse of Dies

In modern presses, a die strikes approximately 120 coins a minute. This is a large number of coins produced in a short time, and obviously the die cannot last forever. However, the process of wearing the die is only hastened by the metals used in coins. Nickel, one of the main metals used in today’s coins, is quite hard and causes wear quickly. Copper has been used for centuries because of its malleability and the ease with which it makes coins. However, it too wears the dies when they are used for too long. An infamous example is the 1955 "poorman’s double die." This coin is sold as a replacement for the 1955 doubled die cent, but it is no more than Die Deterioration Doubling, caused by wear on the dies.

When a coin is struck, the planchet is not heated. Although the planchet would be softer and more malleable, the extra time and expense would prove too great for the Mint. The planchet is therefore struck at room temperature, and the only thing which makes the coin form is the tremendous pressure used to strike it. With a metal such as nickel, which is harder than a normal coin metal like silver, gold or copper, the pressure must be greater. When a nickel coin, or any coin, is struck, the metal must "flow" into the contours of the front and back dies. It is through the atoms of the metal flowing into the dies that flow lines are created. However, when metal flows over a sharp corner in the die, like the edges of a mintmark or words, it tends to roll the detail out. It wears on the die, and a little detail is lost with every strike. Die Deterioration Doubling is most prevalent on the date and mintmark because these fine details are alone in the middle of the field, and the metal must flow into these without the help of other valleys nearby. When the metal rolls into the mintmark or date, it wears away the corner of the die, and after long enough will appear on the coin as Die Deterioration Doubling.

In addition, the mint has a practice of polishing the dies and using them longer. When a die begins to show evidence of wear, a mint technician will polish the die and reuse it. However, the die is still rapidly deteriorating, and polishing it cannot avoid the problem of wear. So, after many thousand coins in rapid succession, the wear on the die has gotten so bad that it appears as Die Deterioration Doubling.

Identification

Die deterioration doubling is a result of a few simple causes, but it can be difficult to positively identify. There are a number of different features which appear similar, but the characteristic traits of each are easy to identify with practice. Die deterioration doubling is often mistaken for hub doubling. The causes of the two types of doubling are different, but their appearance on the finished coin is often similar. Die deterioration doubling appears most often around the mintmark and date because they are alone in the field. When it occurs in other features, like an image of a bust, it looks more like a weak strike than doubling.

Close examination of affected features show that the doubling is extremely irregular. This is because the coin metal does not flow from just one direction, but flows and produces wear on the die from all sides. There is no definite shape, and it can take on several different but similar appearances. It often looks like a thin metal shelf or spreading spot. It can also make lettering appear thick and twisted. There are no crisp lines affected, but things generally look bloated, enlarged, blurry, twisted, and damaged. This is different from hub doubling, because hub doubling appears as a crisp secondary image, rotated minutely from the original. When casually glancing at a coin, the difference is not easy to tell, but when magnified, the difference is obvious on most coins. Another easy way to tell hub doubling from die deterioration doubling is the presence of notched serifs; the small flairs on the ends of letters will appear distinctly separated with the former, whereas they appear just blurry and washed out with the latter.

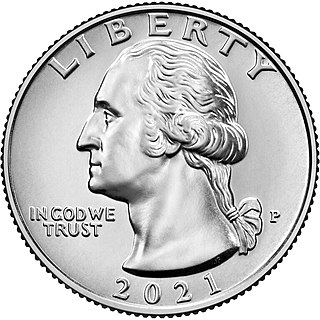

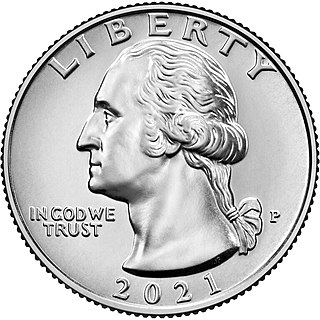

The quarter, short for quarter dollar, is a United States coin worth 25 cents, one-quarter of a dollar. It has a diameter of 0.955 inch (24.26 mm) and a thickness of 0.069 inch (1.75 mm). The coin sports the profile of George Washington on its obverse, and its reverse design has changed frequently. It has been produced on and off since 1796 and consistently since 1831.

The United States one-cent coin, often called the "penny", is a unit of currency equaling one one-hundredth of a United States dollar. It has been the lowest face-value physical unit of U.S. currency since the abolition of the half-cent in 1857. The first U.S. cent was produced in 1787, and the cent has been issued primarily as a copper or copper-plated coin throughout its history. Its obverse has featured the profile of President Abraham Lincoln since 1909, the centennial of his birth. From 1959 to 2008, the reverse featured the Lincoln Memorial. Four different reverse designs in 2009 honored Lincoln's 200th birthday and a new, "permanent" reverse – the Union Shield – was introduced in 2010. The coin is 0.75 inches (19.05 mm) in diameter and 0.0598 inches (1.52 mm) in thickness. Its weight has varied, depending upon the composition of metals used in its production.

1943 steel cents are U.S. one-cent coins that were struck in steel due to wartime shortages of copper. The Philadelphia, Denver, and San Francisco mints each produced these 1943 Lincoln cents. The unique composition of the coin has led to various nicknames, such as wartime cent, steel war penny, zinc cent and steelie. The 1943 steel cent features the same Victor David Brenner design for the Lincoln cent which had been in use since 1909.

Mint-made errors are errors during the minting process. Groups of coins with distinctive characteristics are known as varieties. The term variety applies to coins with both intended and unintended differences while the term error refers only to coins with unintended differences. Nevertheless, not all errors are varieties. Although there may be many identical examples of some errors, others are unique. For example, there may be many indistinguishable examples of coins with a specific die crack, while off-center strikes tend to be unique. Being unique does not mean that an error is valuable. Although no other coin may be similar to a coin with an off-center strike, off-center strikes happen often enough that buyers can choose from many examples each of which varies slightly from the other. Mint error coins can be the result of deterioration of the minting equipment, accidents or malfunctions during the minting process, or intentional interventions by mint personnel. Accidental error coins are perhaps the most numerous and in modern minting are usually very rare, making them valuable to numismatists. Intentional intervention by mint personnel does not necessarily include a deliberate attempt to create an error, but usually involves an action intended to improve quality that miscarries and creates error coins instead. Errors can be the result of defective planchets, defective dies or the result of mistakes made during striking. The planchet, die, and striking classification system happens to correspond with the mintmarks of the three largest U.S. mints, Philadelphia, Denver, and San Francisco. Not all errors fall neatly within the categories. Sometimes design elements are missing from coins because die crevices are filled with grease. Labels used to identify specific categories of errors sometimes describe the cause of the error. Other errors names describe what the viewer sees when looking at the coin while others have names that were adapted for use. The result is that some errors are known by multiple names. Filled die errors are also known as missing design element errors and as strike throughs. As is noted below under the discussion of missing design element coins, some errors have multiple causes. A rare error that sold for $5462.50 on Heritage Auctions in August 2010 is an undated U.S nickel struck on top of a 1960 5 centavos. Foreign coins struck on a U.S coin planchet or vice versa are very uncommon and hold a high value.

The United States Mint is a bureau of the Department of the Treasury responsible for producing coinage for the United States to conduct its trade and commerce, as well as controlling the movement of bullion. It does not produce paper money; that responsibility belongs to the Bureau of Engraving and Printing. The first United States Mint was created in Philadelphia in 1792, and soon joined by other centers, whose coins were identified by their own mint marks. There are currently four active coin-producing mints: Philadelphia, Denver, San Francisco, and West Point.

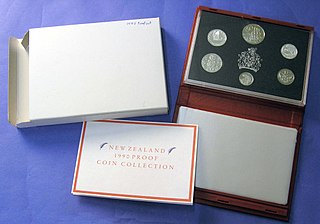

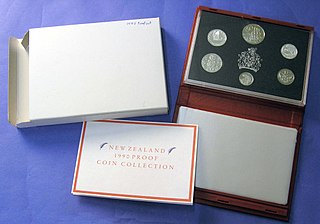

Proof coinage refers to special early samples of a coin issue, historically made for checking the dies and for archival purposes, but nowadays often struck in greater numbers specially for coin collectors (numismatists). Nearly all countries have issued proof coinage.

A planchet is a round metal disk that is ready to be struck as a coin. An older word for planchet is flan. They are also referred to as blanks.

A mint is an industrial facility which manufactures coins that can be used as currency.

The half dime, or half disme, was a silver coin, valued at five cents, formerly minted in the United States.

Doubled die is a term in numismatics used to refer to a duplication of design elements on a working die created due to a misalignment of the die or hub during the hubbing process. Strength of the doubling can vary from very slight and isolated to extreme and widespread. The exact cause of the doubling can also vary, which is why a class system was created to outline the known and hypothesized causes.

The Mercury dime is a ten-cent coin struck by the United States Mint from late 1916 to 1945. Designed by Adolph Weinman and also referred to as the Winged Liberty Head dime, it gained its common name because the obverse depiction of a young Liberty, identifiable by her winged Phrygian cap, was confused with the Roman god Mercury. Weinman is believed to have used Elsie Stevens, the wife of lawyer and poet Wallace Stevens, as a model. The coin's reverse depicts a fasces, symbolizing unity and strength, and an olive branch, signifying peace.

The United States large cent was a coin with a face value of 1/100 of a United States dollar. Its nominal diameter was 11⁄8 inch (28.57 mm). The first official mintage of the large cent was in 1793, and its production continued until 1857, when it was officially replaced by the modern-size one-cent coin.

This glossary of numismatics is a list of definitions of terms and concepts relevant to numismatics and coin collecting, as well as sub-fields and related disciplines, with concise explanations for the beginner or professional.

The Shield nickel was the first United States five-cent piece to be made out of copper-nickel, the same alloy of which American nickels are struck today. Designed by James B. Longacre, the coin was issued from 1866 until 1883, when it was replaced by the Liberty Head nickel. The coin takes its name from the motif on its obverse, and was the first five-cent coin referred to as a "nickel"—silver pieces of that denomination had been known as half dimes.

The Jefferson nickel has been the five-cent coin struck by the United States Mint since 1938, when it replaced the Buffalo nickel. From 1938 until 2004, the copper-nickel coin's obverse featured a profile depiction of founding father and third U.S. President Thomas Jefferson by artist Felix Schlag; the obverse design used in 2005 was also in profile, though by Joe Fitzgerald. Since 2006 Jefferson's portrayal, newly designed by Jamie Franki, faces forward. The coin's reverse is still the Schlag original, although in 2004 and 2005 the piece bore commemorative designs.

The Canadian silver dollar was first issued by the Royal Canadian Mint in 1935 to commemorate the Silver Jubilee of King George V. The coin's reverse design was sculpted by Emanuel Hahn and portrays a voyageur and a person of Indigenous descent paddling a birch-bark canoe. The faint lines in the background represent the Northern Lights. The voyageur design was used on the dollar until 1986. It was then replaced with the 1987 Canadian 1-dollar coin. 1967 marked the end of the silver dollar as a business strike, or a coin issued for circulation. After 1967, the dollar coin was made of nickel, except for non-circulating commemorative issues for the collector market, which continue to contain silver.

In minting, coining or coinage is the process of manufacturing coins using a kind of stamping which is now generically known in metalworking as "coining". This process is different from cast coinage, and can be classified in hammered coinage or hammering and milled coinage or milling.

The Lincoln cent is a one-cent coin that has been struck by the United States Mint since 1909. The obverse or heads side was designed by Victor David Brenner, as was the original reverse, depicting two stalks of wheat. The coin has seen several reverse, or tails, designs and now bears one by Lyndall Bass depicting a Union shield. All coins struck by the United States government with a value of 1/100 of a dollar are called cents because the United States has always minted coins using decimals. The penny nickname is a carryover from the coins struck in England, which went to decimals for coins in 1971.

US error coins are error coins produced by the US government. There are three categories of error coins as provided by the American Numismatic Association. Metal usage and striking errors referred to widely as planchet errors, die errors, and mint striking errors. This does not include the varieties that the US Mint has issued over the years.

The copper-nickel three-cent piece, often called a three-cent nickel piece or three-cent nickel, was designed by US Mint Chief Engraver James B. Longacre and struck by the United States Bureau of the Mint from 1865 to 1889. It was initially popular, but its place in commerce was supplanted by the five-cent piece, or nickel.