Spinning is a twisting technique to form yarn from fibers. The fiber intended is drawn out, twisted, and wound onto a bobbin. A few popular fibers that are spun into yarn other than cotton, which is the most popular, are viscose, animal fibers such as wool, and synthetic polyester. Originally done by hand using a spindle whorl, starting in the 500s AD the spinning wheel became the predominant spinning tool across Asia and Europe. The spinning jenny and spinning mule, invented in the late 1700s, made mechanical spinning far more efficient than spinning by hand, and especially made cotton manufacturing one of the most important industries of the Industrial Revolution.

A cotton gin—meaning "cotton engine"—is a machine that quickly and easily separates cotton fibers from their seeds, enabling much greater productivity than manual cotton separation. The separated seeds may be used to grow more cotton or to produce cottonseed oil.

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses. Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue.

This timeline of clothing and textiles technology covers events relating to fiber and flexible woven material worn on the body. This includes the making, modification, usage, and knowledge of tools, machines, techniques, crafts, and manufacturing systems (technology).

Worsted is a high-quality type of wool yarn, the fabric made from this yarn, and a yarn weight category. The name derives from Worstead, a village in the English county of Norfolk. That village, together with North Walsham and Aylsham, formed a manufacturing centre for yarn and cloth in the 12th century, when pasture enclosure and liming rendered the East Anglian soil too rich for the older agrarian sheep breeds. In the same period, many weavers from the County of Flanders moved to Norfolk. "Worsted" yarns/fabrics are distinct from woollens : the former is considered stronger, finer, smoother, and harder than the latter.

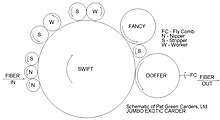

In textile production, carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with "card clothing", a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing.

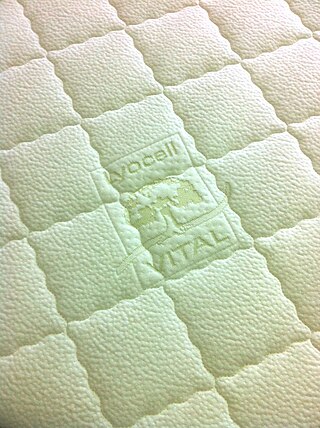

Lyocell is a semi-synthetic fiber used to make textiles for clothing and other purposes. It is a form of regenerated cellulose made by dissolving pulp and dry jet-wet spinning. Unlike rayon made by the more common viscose processes, Lyocell production does not use carbon disulfide, which is toxic to workers and the environment. Lyocell was originally trademarked as Tencel in 1982.

A power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed and patented in 1785 by Edmund Cartwright. It was refined over the next 47 years until a design by the Howard and Bullough company made the operation completely automatic. This device was designed in 1834 by James Bullough and William Kenworthy, and was named the Lancashire loom.

A hole punch, also known as hole puncher, or paper puncher, is an office tool that is used to create holes in sheets of paper, often for the purpose of collecting the sheets in a binder or folder. A hole punch can also refer to similar tools for other materials, such as leather, cloth, or sheets of plastic or metal.

Textile manufacturing or textile engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products.

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be 150 feet (46 m) long, and would move forward and back a distance of 5 feet (1.5 m) four times a minute.

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes. Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel, bar stock, and rails. Most steel mills have rolling mill divisions that convert the semi-finished casting products into finished products.

Cotton-spinning machinery is machines which process prepared cotton roving into workable yarn or thread. Such machinery can be dated back centuries. During the 18th and 19th centuries, as part of the Industrial Revolution cotton-spinning machinery was developed to bring mass production to the cotton industry. Cotton spinning machinery was installed in large factories, commonly known as cotton mills.

Thomas Highs (1718–1803), of Leigh, Lancashire, was a reed-maker and manufacturer of cotton carding and spinning engines in the 1780s, during the Industrial Revolution. He is known for claiming patents on a spinning jenny, a carding machine and the throstle.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, with color and patterns, which turns it into cloth. The machine used for weaving is the loom. For decoration, the process of coloring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Decatising or decatizing, also known as crabbing, blowing, and decating, is the process of making permanent a textile finish on a cloth, so that it does not shrink during garment making. The word comes from the French décatir, which means to remove the cati or finish of the wool. Though used mainly for wool, the term is also applied to processes performed on fabrics of other fibers, such as cotton, linen or polyester. Crabbing and blowing are minor variations on the general process for wool, which is to roll the cloth onto a roller and blow steam through it.

Textile manufacturing is one of the oldest human activities. The oldest known textiles date back to about 5000 B.C. In order to make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving to create cloth. The machine used for weaving is the loom. Cloth is finished by what are described as wet process to become fabric. The fabric may be dyed, printed or decorated by embroidering with coloured yarns.

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

Bradford Industrial Museum, established 1974 in Moorside Mills, Eccleshill, Bradford, United Kingdom, specializes in relics of local industry, especially printing and textile machinery, kept in working condition for regular demonstrations to the public. There is a Horse Emporium in the old canteen block plus a shop in the mill, and entry is free of charge.

Doubling is a textile industry term synonymous with combining. It can be used for various processes during spinning. During the carding stage, several sources of roving are doubled together and drawn, to remove variations in thickness. After spinning, yarn is doubled for many reasons. Yarn may be doubled to produce warp for weaving, to make cotton for lace, crochet and knitting. It is used for embroidery threads and sewing threads, for example: sewing thread is usually 6-cable thread. Two threads of spun 60s cotton are twisted together, and three of these double threads are twisted into a cable, of what is now 5s yarn. This is mercerised, gassed and wound onto a bobbin.