See also

- IBM railway station, near Greenock, Scotland, United Kingdom

IBM is short form for International Business Machines, an American multinational technology and consulting corporation, with headquarters in Armonk, New York.

IBM may also refer to:

In computing, source code, or simply code, is text that conforms to a human-readable programming language and specifies the behavior of a computer. A programmer writes code to produce a program that runs on a computer.

Deep Blue was a chess-playing expert system run on a unique purpose-built IBM supercomputer. It was the first computer to win a game, and the first to win a match, against a reigning world champion under regular time controls. Development began in 1985 at Carnegie Mellon University under the name ChipTest. It then moved to IBM, where it was first renamed Deep Thought, then again in 1989 to Deep Blue. It first played world champion Garry Kasparov in a six-game match in 1996, where it lost four games to two. It was upgraded in 1997 and in a six-game re-match, it defeated Kasparov by winning two games and drawing three. Deep Blue's victory is considered a milestone in the history of artificial intelligence and has been the subject of several books and films.

MI or variants may refer to:

Verification or verify may refer to:

The name Atom applies to a pair of related Web standards. The Atom Syndication Format is an XML language used for web feeds, while the Atom Publishing Protocol is a simple HTTP-based protocol for creating and updating web resources.

IBM Research is the research and development division for IBM, an American multinational information technology company headquartered in Armonk, New York, with operations in over 170 countries. IBM Research is the largest industrial research organization in the world and has twelve labs on six continents.

Moulding or Molding see spelling differences) is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object.

A time clock, sometimes known as a clock card machine, punch clock, or time recorder, is a device that records start and end times for hourly employees at a place of business.

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code.

Blow molding is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes.

IMM or imm may refer to:

Blow-Fill-Seal, also spelled as Blow/Fill/Seal, in this article abbreviated as BFS, is an automated manufacturing process by which plastic containers, such as bottles or ampoules are, in a continuous operation, blow-formed, filled, and sealed. It takes place in a sterile, enclosed area inside a machine, without human intervention, and thus can be used to aseptically manufacture sterile pharmaceutical or non-pharmaceutical liquid/semiliquid unit-dosage forms. BFS is an advanced aseptic processing technology that is typically used for filling and packaging of certain sterile liquid formulations like liquid ophthalmics, inhalational anesthetics, or lavaging agents, but can also be used for injectables, parenteral medicines, and several other liquid or semiliquid medications, with fill volumes ranging from 0.1...1000 cm³. Compared against traditional glass ampoules, BFS ampoules are inexpensive, lightweight, and shatterproof.

Punching is a forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing. Punching is applicable to a wide variety of materials that come in sheet form, including sheet metal, paper, vulcanized fibre and some forms of plastic sheet. The punch often passes through the work into a die. A scrap slug from the hole is deposited into the die in the process. Depending on the material being punched this slug may be recycled and reused or discarded.

Rotary wheel blow molding systems are used for the high-output production of a wide variety of plastic extrusion blow molded articles. Containers may be produced from small, single serve bottles to large containers up to 20-30 liters in volume - but wheel machines are often sized for the volume and dimensional demands of a specific container, and are typically dedicated to a narrow range of bottle sizes once built. Multiple parison machines, with high numbers of molds are capable of producing over one million bottles per day in some configurations.

Open Virtualization Format (OVF) is an open standard for packaging and distributing virtual appliances or, more generally, software to be run in virtual machines.

IBM Watson is a computer system capable of answering questions posed in natural language. It was developed as a part of IBM's DeepQA project by a research team, led by principal investigator David Ferrucci. Watson was named after IBM's founder and first CEO, industrialist Thomas J. Watson.

Gemini Group, Inc. is a supplier of engineered plastic and metal products to OEM's and Tier 1 suppliers. The company operates internationally from its headquarters in Bad Axe, Michigan in the United States.

A Boy and His Atom is a 2013 stop-motion animated short film released on YouTube by IBM Research. One minute in length, it was made by moving carbon monoxide molecules with a scanning tunneling microscope, a device that magnifies them 100 million times. These two-atom molecules were moved to create images, which were then saved as individual frames to make the film. The movie was recognized by the Guinness Book of World Records as the World's Smallest Stop-Motion Film in 2013.

The International Business Machines Corporation, nicknamed Big Blue, is an American multinational technology company headquartered in Armonk, New York and present in over 175 countries. IBM is the largest industrial research organization in the world, with 19 research facilities across a dozen countries, having held the record for most annual U.S. patents generated by a business for 29 consecutive years from 1993 to 2021.

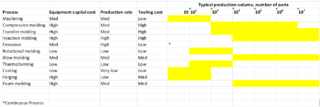

The economics of plastics processing is determined by the type of process. Plastics can be processed with the following methods: machining, compression molding, transfer molding, injection molding, extrusion, rotational molding, blow molding, thermoforming, casting, forging, and foam molding. Processing methods are selected based on equipment cost, production rate, tooling cost, and build volume. High equipment and tooling cost methods are typically used for large production volumes whereas low - medium equipment cost and tooling cost methods are used for low production volumes. Compression molding, transfer molding, injection molding, forging, and foam molding have high equipment and tooling cost. Lower cost processes are machining, extruding, rotational molding, blow molding, thermoforming, and casting. A summary of each process and its cost is displayed in figure 1.