Concrete, usually Portland cement concrete, is a composite material composed of fine and coarse aggregate bonded together with a fluid cement that hardens over time—most frequently in the past a lime-based cement binder, such as lime putty, but sometimes with other hydraulic cements, such as a calcium aluminate cement or Portland Cement. It is distinguished from other, non-cementitious types of concrete all binding some form of aggregate together, including asphalt concrete with a bitumen binder, which is frequently used for road surfaces, and polymer concretes that use polymers as a binder.

Reinforced concrete (RC) (also called reinforced cement concrete or RCC) is a composite material in which concrete's relatively low tensile strength and ductility are counteracted by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel reinforcing bars (rebar) and is usually embedded passively in the concrete before the concrete sets. Reinforcing schemes are generally designed to resist tensile stresses in particular regions of the concrete that might cause unacceptable cracking and/or structural failure. Modern reinforced concrete can contain varied reinforcing materials made of steel, polymers or alternate composite material in conjunction with rebar or not. Reinforced concrete may also be permanently stressed, so as to improve the behaviour of the final structure under working loads. In the United States, the most common methods of doing this are known as pre-tensioning and post-tensioning.

John Smeaton was an English civil engineer responsible for the design of bridges, canals, harbours and lighthouses. He was also a capable mechanical engineer and an eminent physicist. Smeaton was the first self-proclaimed "civil engineer", and is often regarded as the "father of civil engineering". He pioneered the use of hydraulic lime in concrete, using pebbles and powdered brick as aggregate. Smeaton was associated with the Lunar Society.

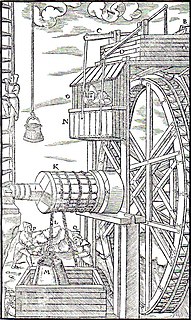

Mechanization is the process of changing from working largely or exclusively by hand or with animals to doing that work with machinery. In an early engineering text a machine is defined as follows:

Every machine is constructed for the purpose of performing certain mechanical operations, each of which supposes the existence of two other things besides the machine in question, namely, a moving power, and an object subject to the operation, which may be termed the work to be done.

Machines, in fact, are interposed between the power and the work, for the purpose of adapting the one to the other.

Ferrocement or ferro-cement is a system of reinforced mortar or plaster applied over layer of metal mesh, woven expanded-metal or metal-fibers and closely spaced thin steel rods such as rebar. The metal commonly used is iron or some type of steel. It is used to construct relatively thin, hard, strong surfaces and structures in many shapes such as hulls for boats, shell roofs, and water tanks. Ferrocement originated in the 1840s in France and is the origin of reinforced concrete. It has a wide range of other uses including sculpture and prefabricated building components. The term "ferrocement" has been applied by extension to other composite materials, including some containing no cement and no ferrous material.

Sir Ove Nyquist Arup, CBE, MICE, MIStructE, FCIOB was an English engineer who founded Arup Group Limited, a multinational corporation that offers engineering, design, planning, project management, and consulting services for building systems. Ove Arup is considered to be among the foremost architectural structural engineers of his time.

Engineered Cementitious Composite (ECC), also called Strain Hardening Cement-based Composites (SHCC) or more popularly as bendable concrete, is an easily molded mortar-based composite reinforced with specially selected short random fibers, usually polymer fibers. Unlike regular concrete, ECC has a strain capacity in the range of 3–7%, compared to 0.01% for ordinary portland cement (OPC) paste, mortar or concrete. ECC therefore acts more like a ductile metal like material rather than a brittle glass like material, leading to a wide variety of applications.

The Paulinskill Viaduct, also known as the Hainesburg Viaduct, is a reinforced concrete railroad bridge that crosses the Paulins Kill in Knowlton Township, New Jersey. When completed in 1910, it was the largest reinforced concrete structure in the world.

The technology history of the Roman military covers the development of and application of technologies for use in the armies and navies of Rome from the Roman Republic to the fall of the Western Roman Empire. The rise of Hellenism and the Roman Republic are generally seen as signalling the end of the Iron Age in the Mediterranean. Roman iron-working was enhanced by a process known as carburization. The Romans used the better properties in their armaments, and the 1,300 years of Roman military technology saw radical changes. The Roman armies of the early empire were much better equipped than early republican armies. Metals used for arms and armor primarily included iron, bronze, and brass. For construction, the army used wood, earth, and stone. The later use of concrete in architecture was widely mirrored in Roman military technology, especially in the application of a military workforce to civilian construction projects.

Joseph Monier was a French gardener and one of the principal inventors of reinforced concrete.

Terence Patrick O'Sullivan (1913-1970) was a British civil engineer. He specialised initially in steel and reinforced concrete structures. Later he founded a firm of consulting engineers, T. P. O’Sullivan & Partners, which grew to have offices on four continents and made a reputation in the field of infrastructure development, particularly in the developing world.

Concrete has relatively high compressive strength, but significantly lower tensile strength. As a result, without compensating, concrete would almost always fail from tensile stresses – even when loaded in compression. The practical implication of this is that concrete elements subjected to tensile stresses must be reinforced with materials that are strong in tension. The elasticity of concrete is relatively constant at low stress levels but starts decreasing at higher stress levels as matrix cracking develops. Concrete has a very low coefficient of thermal expansion, and as it matures concrete shrinks. All concrete structures will crack to some extent, due to shrinkage and tension. Concrete which is subjected to long-duration forces is prone to creep. The density of concrete varies, but is around 2,400 kilograms per cubic metre (150 lb/cu ft).

Walter Mickle Smith, Sr. was a civil engineer who worked primarily on U.S. dams and waterway projects. He was a consulting engineer on the construction of the Panama Canal and Panama Canal Locks and later served as design engineer for the New York Board of Water Supply. He spent much of his career with the State of Illinois waterways division and was its chief engineer until his retirement in 1937. Several of his works built in the 1920s and 1930s as part of the Illinois Waterway project are listed on the National Register of Historic Places, including portions of the Brandon Road Lock and Dam, the Dresden Island Lock and Dam, the Lockport Lock and Power House, and the Marseilles Lock and Dam.

Herbert William Charles Kempton Dyson, M.I.Struct.E. (1880–1944), known professionally as H. Kempton Dyson, was an English structural engineer, civil engineer, architect, editor and author who specialised in reinforced concrete structures. He was a founder member and the first permanent secretary of the Concrete Institute, which became the Institution of Structural Engineers. He designed the Central Bandstand, Herne Bay in 1924.

Julius Kahn was an engineer, industrialist, and manufacturer. He was the inventor of the Kahn System, a reinforced concrete engineering technique for building construction. The Kahn System that he patented in 1903 was used worldwide for housing, factories, office and industrial buildings. His system was used in 134 US cities by 1939. His engineering system for building construction was also found then in Africa, Europe, Canada, China, Brazil, and Mexico. In Yokohama, Japan, his system was used in an automobile factory. His unique engineering system of construction was used also in airplane plants, warehouses, docks, foundries, creameries, filtration plants, rubber factories, steel plants, silos, distilleries, smelters, and textile mills.

Thos. W. Ward Ltd was a Sheffield, Yorkshire, steel, engineering and cement business which began as coal and coke merchants then expanded to recycling metal for Sheffield's steel industry, engineering and the supply of machinery.

Ira Nelson Hollis was an American mechanical engineer at the US Navy, Professor of engineering at Harvard University, and president of Worcester Polytechnic Institute. He served as president of the American Society of Mechanical Engineers in the year 1917-18.

Medlow Dam is a heritage-listed major gated concrete-walled arch dam across the Adams Creek in the Blue Mountains region, located at Beauchamp Road, Medlow Bath in the City of Blue Mountains local government area of New South Wales, Australia. The dam was designed and built in 1907 by the NSW Department of Public Works. The dam's purpose includes is primarily for the potable water supply of the upper Blue Mountains region. The impounded reservoir is called Medlow Bath Reservoir. The dam is also known as Medlow Bath Dam, Lake Medlow Dam, Adams Creek Dam and Medlow Bath Reservoir. The property is owned by Sydney Water, a state-owned corporation of the Government of New South Wales. The dam was added to the New South Wales State Heritage Register on 18 November 1999.

Leslie Arthur Clark OBE., FREng, FIStructE is a British structural engineer born in 1944 in Ilford, London.