Related Research Articles

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy.

A locomotive or engine is a rail transport vehicle that provides the motive power for a train. If a locomotive is capable of carrying a payload, it is usually rather referred to as a multiple unit, motor coach, railcar or power car;

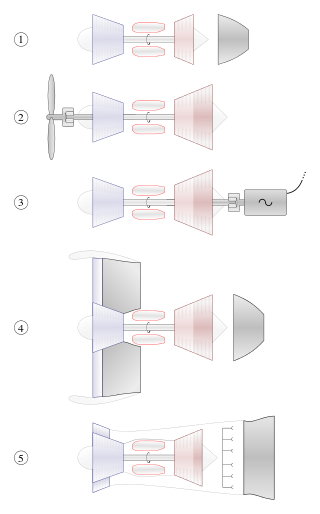

A gas turbine or gas turbine engine, by its old name internal combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part and are, in the direction of flow:

A four-strokeengine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed:

- Intake: Also known as induction or suction. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). In this stroke the intake valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing a partial vacuum in the cylinder through its downward motion.

- Compression: This stroke begins at B.D.C, or just at the end of the suction stroke, and ends at T.D.C. In this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke (below). Both the intake and exhaust valves are closed during this stage.

- Combustion: Also known as power or ignition. This is the start of the second revolution of the four stroke cycle. At this point the crankshaft has completed a full 360 degree revolution. While the piston is at T.D.C. the compressed air-fuel mixture is ignited by a spark plug or by heat generated by high compression, forcefully returning the piston to B.D.C. This stroke produces mechanical work from the engine to turn the crankshaft.

- Exhaust: Also known as outlet. During the exhaust stroke, the piston, once again, returns from B.D.C. to T.D.C. while the exhaust valve is open. This action expels the spent air-fuel mixture through the exhaust port.

The Rover Company Limited was a British car manufacturing company that operated from its base in Solihull in Warwickshire. Its lasting reputation for quality and performance was such that its first postwar model reviewed by Road & Track in 1952 was pronounced finer than any but a Rolls-Royce. Rover also manufactured the Land Rover series from 1948 onwards, which spawned the Range Rover in 1970, and went on to become its most successful and profitable product — with Land Rover eventually becoming a separate company and brand in its own right.

An opposed-piston engine is a piston engine in which each cylinder has a piston at both ends, and no cylinder head. Petrol and diesel opposed-piston engines have been used mostly in large-scale applications such as ships, military tanks, and factories. Current manufacturers of opposed-piston engines include Cummins, Achates Power and Fairbanks-Morse Defense (FMDefense).

The Rover 200 Series, and later the Rover 25, are a series of small family cars that were produced by British manufacturer Rover from 1984 until 2005.

British Racing Motors (BRM) was a British Formula One motor racing team. Founded in 1945 and based in the market town of Bourne in Lincolnshire, it participated from 1951 to 1977, competing in 197 grands prix and winning seventeen. BRM won the constructors' title in 1962 when its driver Graham Hill became world champion. In 1963, 1964, 1965 and 1971, BRM came second in the constructors' competition.

British Rail 18000 was a prototype mainline gas turbine-electric locomotive built for British Railways in 1949 by Brown, Boveri & Cie. An earlier gas-turbine locomotive, 18100, had been ordered from Metropolitan-Vickers by the Great Western Railway but construction was delayed due to World War II; a second, 18000, was thus ordered from Switzerland in 1946. It spent its working life on the Western Region of British Railways, operating express passenger services from Paddington station, London.

The Austin Motor Company A-series is a British small straight-4 automobile engine. Launched in 1951 with the Austin A30, production lasted until 2000 in the Mini. It used a cast-iron block and cylinder head, and a steel crankshaft with three main bearings. The camshaft ran in the cylinder block, driven by a single-row chain for most applications, and with tappets sliding in the block, accessible through pressed steel side covers for most applications, and with overhead valves operated through rockers. The cylinder blocks are not interchangeable between versions intended for conventional end-on mounted gearboxes and the 'in-sump' transaxle used on British Motor Corporation/British Leyland front wheel drive models such as the Mini. The cylinder head for the overhead-valve version of the A-series engine was designed by Harry Weslake – a cylinder head specialist famed for his involvement in SS (Jaguar) engines and several Formula One-title winning engines. Although a "clean sheet" design, the A-series owed much to established Austin engine design practise, resembling in general design and overall appearance a scaled-down version of the 1200cc overhead-valve engine first seen in the Austin A40 Devon which would form the basis of the later B-series engine.

The Chrysler Turbine Car is an experimental two-door hardtop coupe powered by a turbine engine and manufactured by Chrysler from 1963 to 1964. The bodywork was constructed by Italian design studio Carrozzeria Ghia and Chrysler completed the final assembly in Detroit. A total of 55 cars were manufactured: five prototypes and a limited run of 50 cars for a public user program. All have a signature metallic paint named "turbine bronze", roughly the color of root beer. The car was styled by Elwood Engel and the Chrysler studios and featured power brakes, power steering, and a TorqueFlite transmission.

The General Motors Firebird comprises a quartet of prototype cars that General Motors (GM) engineered for the 1953, 1956, and 1959 Motorama auto shows. The cars' designers, headed by Harley Earl, took Earl's inspiration from the innovations in fighter aircraft design at the time. General Motors never intended the cars for production, but rather to showcase the extremes in technology and design that the company was able to achieve.

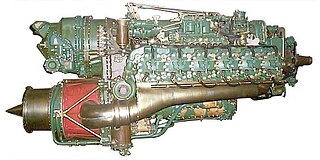

The Rolls-Royce Meteorite, also known as the Rover Meteorite, was a post-war British 18.01 L (1,099 cu in) V8 petrol or diesel engine was derived from the Rolls-Royce Meteor tank engine.

Marine propulsion is the mechanism or system used to generate thrust to move a watercraft through water. While paddles and sails are still used on some smaller boats, most modern ships are propelled by mechanical systems consisting of an electric motor or internal combustion engine driving a propeller, or less frequently, in pump-jets, an impeller. Marine engineering is the discipline concerned with the engineering design process of marine propulsion systems.

A turbo-compound engine is a reciprocating engine that employs a turbine to recover energy from the exhaust gases. Instead of using that energy to drive a turbocharger as found in many high-power aircraft engines, the energy is instead sent to the output shaft to increase the total power delivered by the engine. The turbine is usually mechanically connected to the crankshaft, as on the Wright R-3350 Duplex-Cyclone, but electric and hydraulic power recovery systems have been investigated as well.

The Rover-BRM was a prototype gas turbine-powered racing car, jointly developed in the early 1960s by the British companies Rover and British Racing Motors (BRM). The car is part of the collection at the British Motor Museum.

A liquid nitrogen vehicle is powered by liquid nitrogen, which is stored in a tank. Traditional nitrogen engine designs work by heating the liquid nitrogen in a heat exchanger, extracting heat from the ambient air and using the resulting pressurized gas to operate a piston or rotary motor. Vehicles propelled by liquid nitrogen have been demonstrated, but are not used commercially. One such vehicle, Liquid Air, was demonstrated in 1902.

The Rover JET1 was a gas turbine car originally built in Solihull in 1949/1950 by the Rover Company, and modified to a more aerodynamic style in 1952. It held a world speed record for a gas turbine-powered car in 1952 with a speed of 152.691 mph. Rover won the Dewar Trophy in 1950 for this work, in recognition of its outstanding pioneering achievement. It was the first time this trophy had been awarded since 1929.

The GMWhirlfire gas turbine engines were developed in the 1950s by the research division of General Motors Corporation and fitted to concept vehicles, including the Firebird concept cars, Turbo-Cruiser buses, and Turbo-Titan trucks through the 1960s. They are free-turbine turboshaft machines with two spools: one compressor/gasifier turboshaft and one power/output turboshaft sharing a common axis without a mechanical coupling between them. Fuel consumption of the first-generation GT-300 was high compared to piston engines, so thermal wheel regenerators were added to the second-generation GT-304, cutting consumption by approximately 1⁄2.

Rover T3 is a gas turbine-powered coupé developed in the 1950s by the Rover Company. Showcasing Britain's leading role in the development of this new technology, the Rover T3 was launched at the Earls Court Motor Show in November 1956 ., which was captured on film by British Pathé. The T3 coupé was Rover’s third turbine car, designed by Charles Spencer King and Gordon Bashford.

References

Citations

- ↑ Garrett, Newton & Steeds 2000, p. 679.

- ↑ Norbye 1975, p. 260.

- 1 2 3 4 Barnard & Phillips 1974, p. 2.

- ↑ Mortimer 2015, p. 137.

- 1 2 Barnard & Phillips 1974, p. 3.

- ↑ Barnard & Phillips 1974, p. 6.

- ↑ Barnard & Phillips 1974, pp. 10–11.

- ↑ Mortimer 2015, p. 139.

- ↑ Barnard & Phillips 1974, p. 12.

- 1 2 Favorsky, Oleg (2009). Thermal to Mechanical Energy Conversion :Engines and Requirements. EOLSS. p. 5. ISBN 9781848260221.

- 1 2 Mortimer 2015, p. 138.

Bibliography

- Barnard, M.C.S.; Phillips, P.A. (March 1974). The British Leyland 2S/350/R Gas Turbine Engine (PDF). Gas Turbine Conference. Zurich: American Society of Mechanical Engineers.

- Turbine cost competes at 2,500 units a year Commercial Motor 24 January 1965

- The Rover Turbine Cars

- Garrett, T. K.; Newton, K.; Steeds, W. (2000). The Motor Vehicle. Butterworth-Heinemann. pp. 679–680. ISBN 9780080537016.

- Norbye, Jan (1975). The Gas Turbine Engine: Design, Development, Applications. Chilton. ISBN 9780801957536.

- Mortimer, John (2015). The nearly engine. Chilton. ISBN 9781326177072.